Blogs

OIL FILM THICKNESS MEASUREMENT

Industry Automotive Applications Oil Film Measurement Type Level Description A top marine engine manufacturer commissioned MTI Instruments to design and manufacture a non-contact sensor to measure the microscopic oil film layer between the engine cylinder wall and the piston ring. Engine testing is normally performed through a range of low RPM’s to high RPM’s (400- 6000) with piston linear speeds approaching 500 inches/second and at various torques. A measuring system with high frequency response and small sensor size was essential to keep engine machining to a minimum while not altering [...]

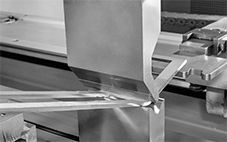

Angle Measurement And Monitoring

Angle Measurement And Monitoring Industrial Angle Measurement And Monitoring Robot Guide Description Introduction So what do sheet metal, speakers, and wine bottles all have in common? They represent the many angles and profiles that can be measured with laser sensor head. Angles: Numerous applications call for measuring angles such as sheet metal Press Brake applications. As the Press Brake bends the sheet metal, the controller reads the actual bend angle from the sensor head and can control under/over bending to reduce product waste and time. Sensor measurements can easily be interfaced [...]

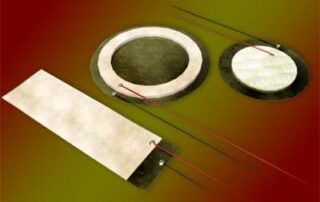

Piezoelectric Device Amplitude

Piezoelectric Device Amplitude Research & Development Piezoceramic, 1-3 Pzt / Polymer Composite And Pvdf Film Amplitude Description Measuring Piezoelectric device amplitude including piezoceramic, 1-3 PZT/polymer composite and PVDF film A “PZT ” is a piezoelectric device which generates motion when a voltage is applied across the crystal. The motion can be anywhere from DC to ultrasonic and the motion is typically very small. PZT devices are used to generate sound and to convert voltage to motion. MTI's MTI-2100 controller in conjunction with a High resolution fiber optic probe such as [...]

Tire Tread Measurement

Tire Tread Measurement Automotive Tire Tread Inspection Depth Description Tire manufacturers and Used Tire Reuse Centers want to satisfy their customers, and protect themselves from liabilities. Manufacturers are moving to 100% tire inspection for tread depth, defects and abnormality detection. Defects not only cause potential safety issues but they can also introduce unwanted vibration into the vehicle suspension system and cause excessive road noise. Belts can be overlapped, or not cover the complete tire surface, causing weak or bubbled areas and imbalances. The tread depth can be too shallow, leading [...]

Brake Rotors

Brake Rotors Automotive Brake Rotors Surface Description Introduction Under normal operating conditions brake rotors are subjected to extreme temperatures and forces, which can cause rotor distortion and potential failure. To make certain it can withstand these conditions; extensive laboratory testing is performed to optimize design for longevity, short stopping distance, and vibration free operation. Extensive on-vehicle testing is done under real life conditions to test prototype units and engineering designs. Test vehicles are driven for long periods of time while brake performance is monitored by a variety of sensors and data [...]

Wafer Characterization

Semiconductor Wafer Characterization Surface Description Thickness Measurement ASTM F657: The distance through a wafer between corresponding points on the front and back surface. Thickness is expressed in microns or mils (thousandths of an inch). Total Thickness Variation (TTV) ASTM F657: The difference between the maximum and minimum values of thickness encountered during a scan pattern or series of point measurements. TTV is expressed in microns or mils (thousandths of an inch). Figure above shows a wafer placed between two non-contact measurement probes. By monitoring changes between the upper probe [...]

Solenoid Door Latches

Solenoid Door Latches Aviation/ Aerospace Solenoid Door Latches Displacement Description A key supplier to the aerospace industry who manufactures many types of solenoid door latches was faced with the requirement to measure the motion of the lock plunger. Since the solenoid latch needs to complete the locking or unlocking cycle in as quickly as 13 milliseconds, it was critical to accurately track the fast motion of the plunger with a measurement system having a frequency response in excess of 100kHz. Because of the limited access to the interior of the [...]

Fiber Optic Probes Measure Stator Bar Vibration

Fiber Optic Probes Measure Stator Bar Vibration Power Generation, Industrial Stator Bar Vibration In A High Magnetic Field Amplitude Description [Application Note 11718] One of the primary concerns in large generator design is vibration. Excessive vibration can lead to premature breakdown of insulation and other materials, ultimately resulting in early failure of the generator itself. The Problem A leading manufacturer of power generating equipment required a sensing system able to measure stator bar vibration in a partial generator mockup. Specifically, the company's multi-day testing program demanded a sensing system that was [...]

Nuclear Heat Exchanger Vibration

Nuclear Heat Exchanger Vibration Power Generation Nuclear Heat Exchanger Vibration Amplitude Description Introduction: Power plants, particularly nuclear power plants, require heat exchangers to cool down the primary working fluid for the power plant. Excessive vibration can lead to cracking and premature failure of the heat exchanger. Problem: A major power plant company approached MTI looking for a sensor that could measure vibration of a heat exchanger assembly that was immersed under water. Additionally, the water could reach 250 F and up to 220 PSI; the probe had to be sealed [...]

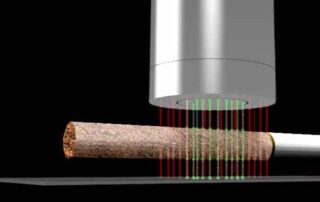

In-Situ Particle Detection

In-Situ Particle Detection Research & Development In-Situ Particle Detection Presence/Absence Description Introduction:  Foreign particles in food stuffs, plant produce, grains, etc. can lead to customer dissatisfaction when the items are packaged for sale. In some cases — it can be dangerous. Opportunity:  A major cigarette producer contacted MTI Instruments requesting a system to detect extraneous material, metal, plastic, filter fiber, and other contaminants. Background:  A cigarette’s dielectric footprint is controlled by the tobacco packing density, moisture content and the type of tobacco leaf. - packing density is controlled by the [...]