Blogs

Wireless Measurement of Very Small Gap Changes Inside Rotating Machinery

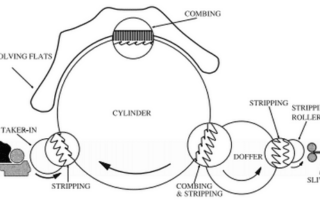

Solar, Semiconductor Measurement of Ungrounded Targets Thickness, Metrology Description Description This application note describes how to use capacitance for the non-contact, wireless measurement of very small gap changes (distances) between a device and a grounded target. It uses the textile industry as an example, but any industry that uses machinery with continuously rotating drums or motors can benefit from this approach to remote measurement. Capacitance is highly accurate and can support the use of probes that are wireless. In our example, a capacitive sensing system from MTI Instruments eliminated concerns about establishing and maintaining [...]

MTI’s Accumeasure HD Amplifier vs. SmarAct’s PicoScale Interferometer

MTI's Accumeasure HD Amplifier vs. SmarAct's PicoScale Interferometer Research & Development Piezoceramic, 1-3 Pzt / Polymer Composite And Pvdf Film Amplitude Description This application note compares MTI's Accumeasure HD amplifier to SmarAct's Picoscale interferometer in terms of resolution and accuracy for very small displacement measurements. Specifically, this comparison focuses on minimum expected resolution and the effects of noise on accuracy. High resolution interferometers are widely regarded as the instrument of choice for the type of measurements described in this application note, but MTI's technology provides exceptional accuracy and stability. Moreover, [...]

Testing for Connector Failure Due to Vibration or Shock

Testing for Connector Failure Due to Vibration or Shock Mobile Communications Equipment Needs Reliable Connectors That Will Not Disconnect with Shock or Vibration Introduction A large multinational company approached MTI to provide a sensor capable of measuring displacement that also wouldn’t load the target (connector). Shock and vibration testing would span 2-15G and the target connectors were very small. Application MTI’s 2100 optical displacement sensor system is ideal for this kind of application because very small probes can be used and they measure displacement via reflected light. Of course, reflected light does [...]

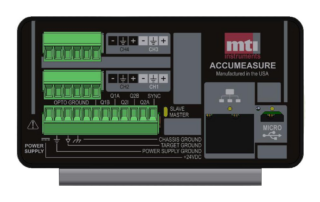

Connecting Encoders to MTI’s Digital Accumeasure

Connecting Encoders to MTI's Digital Accumeasure MTI's Digital Accumeasure D has the ability to accept one or two digital quadrature encoders. The encoders can be linear slide-type or rotary. Digital encoders allow for tracking the position of capacitive probes such that you can synchronize a probe's position with the probe's displacement data. Two common examples are: Rotary shaft runout: shaft (radial) displacement vs. angular encoder position X/Y position of probes measuring wafer thickness (map wafer thickness) Accumeasure software (basic and measurement) allows the display of instantaneous encoder counts as well as probe displacement data; however, [...]

Foam Density Measurement: Capacitance Sensors vs. Nuclear Gauges

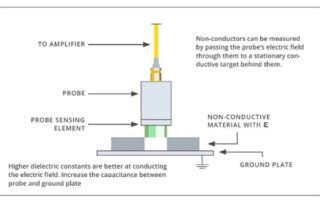

Foam Density Measurement: Capacitance Sensors vs. Nuclear Gauges Foam Density Measurement Manufacturing EV Battery Production Thickness, Distance This application note from MTI Instruments compares two technologies for measuring foam density: capacitance sensors and nuclear gauges. It examines the basic operating principles of each technology and explains why capacitance measurement is recommended for in-line measurement during foam manufacturing. Capacitance Sensors Capacitive probes are non-contact devices that use electric fields to measure foam density. In combination with a thickness value, a density measurement may be calculated. These probes consist of a capacitance [...]

Thickness Measurement of Dielectric Materials

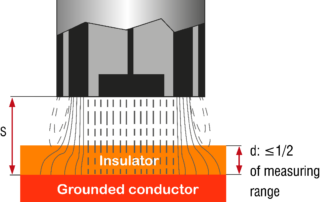

Thickness Measurement of Dielectric Materials Manufacturing EV Battery Production Thickness, Distance --- Description --- Introduction Many applications, both in manufacturing and research, require precise material thickness measurements. This becomes especially difficult if the material is moving, is non conductive and/or translucent to clear. The specifics of your application may make accurate measurements difficult; many circumstances prohibit contact measurement, and make laser measurements difficult or impossible, for example with thin clear materials such as glass, sapphire, plastic . In cases such as these, capacitance measurement provides a highly accurate and cost-effective solution. [...]

Comparing Non-Contact Sensors: Capacitive vs. Eddy Current Sensors

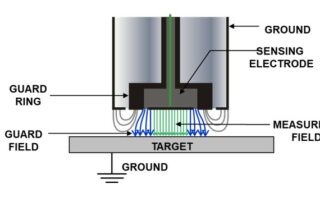

Comparing Non-Contact Sensors: Capacitive vs. Eddy Current Sensors Comparing Non-Contact Sensors: Capacitive vs. Eddy Current Sensors Manufacturing EV Battery Production Thickness, Distance This application note from MTI Instruments compares two types of non-contact sensors: capacitive and Eddy current. It describes their basic operating principles, includes a quick comparison table, and offers recommendations for use. Capacitance Sensors: Basic Operating Principles Capacitive probes use electric fields to measure the distance from the sensor face to the target surface. A guard ring around the capacitive sensor in the probe steers the direction of [...]

Windshield Manufacturing

Industry Automotive Applications Oil Film Measurement Type Level Description In order to maintain proper profile and thickness within a glass furnace the extrusion plate spacing must be maintained at a predetermined gap. Unfortunately, due to process changes and temperature swings this gap can fluctuate significantly in short periods of time. This variation causes the glass thickness to change (check out our glass thickness measurement devices to accurately measure thickness), producing uneven temperature gradients and creating potentially weak glass panels. To control this critical parameter the manufacturing process requires automated active feedback [...]

Vibration and Balancing Systems: The Spectrum Plot

The Spectrum Plot: Types of Aircraft Vibration One of the least understood features of the PBS series of vibration analyzers is the spectrum function. The spectrum functionality is a more difficult function to understand, but once mastered, technicians can quickly develop an extremely in-depth understanding on what is going on in an engine during a test. Figure 1, below, shows a basic spectrum from the PBS system. On the x-axis is frequency, measured in Hz (per second). On the y-axis is amplitude, measured in units of velocity, inches per second pk, or IPS pk. Figure 1: Basic Spectrum [...]

Ideal Charge Amplifier for Piezo Electric Transducers

Ideal Charge Amplifier for Piezo Electric Transducers Aviation (Turbine Engines), Automotive Research and Development, Industrial Manufacturing Vibration Monitoring: Turbine Engines; Vehicle Testing Pressure Monitoring: Combustion Engines; Pumps, Turbines Amplitude Measurements:  Acceleration, Vibration, Pressure Description Ideal Charge Amplifier for Piezo Electric Transducers Piezoelectric-type transducers such as accelerometers used for turbine vibration measurement and pressure transducers used for combustion dynamics monitoring (CDM) produce a high-impedance charge output that must be conditioned and amplified before transmission across system cabling and into measurement instrumentation. Challenge A piezoelectric transducer is a sensor that produces a [...]