Blogs

The Growing Need for Industry 4.0 Testing and Validation Tools

Industry 4.0 means that manufacturers need to test and validate more sensors. MTI Instruments 1510A portable signal generator can help. Industry 4.0 is spurring a dramatic increase in the number of sensors that manufacturers need to install, test, validate, and maintain. Although these industrial sensors are packaged to withstand harsh environments, they’re still susceptible to performance-related problems. Whether it’s to support predictive maintenance, asset monitoring, or process automation, proper testing and validation is required to keep systems running smoothly. Otherwise, the data that sensors collect won’t enable the operators of smart factories to make the right decisions. Smart [...]

Silicon Carbide vs. Silicon in EV Power Electronics

Compare silicon carbide vs. silicon for electric vehicle (EV) power electronics and learn about SiC wafer measurement. As demand for electric vehicles (EVs) continues to grow, manufacturers are comparing two semiconductor technologies, silicon carbide and silicon, for power electronics applications. Silicon carbide (SiC) provides the high temperature resistance, low power consumption, rigidity, and support for smaller, thinner designs that EV power electronics need. Examples of SiC’s current applications include on-board DC/DC converters, off-board DC fast chargers, on-board battery chargers, EV powertrains, and automotive lighting for LEDs. According to Automotive World, SiC technology could also drive future EV innovations [...]

EV Batteries Need Thickness Gauging for Lower Costs and Higher Performance

EV batteries need to cost less and last longer. Until the e-mobility industry solves these challenges, electric vehicle (EV) adoption won’t match the hype that’s driven by Tesla, the established automakers, and a host of startups who are attracting investors. According to Axios, the expense of owning an electric vehicle will exceed that of owning a conventional one until EV batteries cost less than $100/KWh to produce. Unfortunately, the EV industry isn’t expected to hit that target for another ten years. Yet, there is some encouraging news. Less expensive and better performing EV batteries are just a few years [...]

Transducer Selection for High Resolution Applications

High resolution applications do not always require an interferometer. If you want to make accurate measurements in the micron to picometer range, then an MTI Digital Accumeasure D100 HD or D200 system may be what you need. Laser interferometers can sell for more than $15,000 and be difficult to setup. For example, you may have to buy additional optics to guarantee a good return signal since the laser beam must reflect off a mirror surface or precision retro reflector in order for the beam to re-enter the interferometer’s optics at less than a degree of reflection angle. The downsides [...]

High Resolution Semiconductor Wafer Measurements at Lower Costs

MTI's Proforma technology characterizes semiconductor wafers in terms of bow and warp, thickness, total thickness variation (TTV) and center thickness. Until recently, semiconductor wafer measurements at resolutions less than 100 µm were cost-prohibitive. Moreover, only expensive devices such as interferometers were capable of these measurements. Today, the semiconductor industry can use capacitance gauges instead of laser interferometers to achieve high resolution at fraction of the cost. Much like affordable CCD cameras transformed and expanded the market for video, cost-effective capacitance is disrupting the semiconductor wafer measurement market and creating new opportunities for quality testing and validation. The [...]

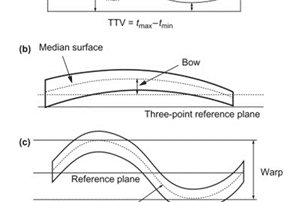

Measure Wafer Bow, Warp and TTV with Capacitance

The flatness of silicon wafers used to manufacture integrated circuits is controlled to tight tolerances to help ensure that the whole wafer is sufficiently flat for lithographic processing. To ensure your wafer manufacturing process is within tolerance, you need to measure the wafers being produced. Various measurement techniques exist to verify process tolerances and eliminate expensive scrap wafers. Non-contact capacitive sensing is a highly precise and cost-effective means to measure wafer flatness, bow, warp, and total thickness variation (TTV). MTI Instruments’ Proforma 300i and 300iSA systems use capacitance sensors to improve yields while reducing costs through better dimensional control of [...]

How to Measure Dielectric Separator Thickness in EV Batteries

The International Energy Agency predicts that as many as 125 million electric vehicles (EVs) will be on the road by 2030. At the heart of these electric cars, trucks, and buses is the lithium-ion (Li-ion) battery, a type of rechargeable battery with high energy density and low self-discharge. The plates in Li-ion batteries consist of lithium compounds that are applied to either a copper plate substrate (cathode) or an aluminum substrate (anode). In turn, these two plates are separated by a dielectric separator. All of the layers in an EV battery are extremely thin. In fact, the cathode and [...]

Capacitance Sensing for Non-Contact Thickness Measurements of Insulating Materials

Capacitance sensing can be used to make non-contact thickness measurements for most insulating materials. Capacitance sensors are known for their ability to precisely measure the thickness and position of conductive targets, but what’s less known is that these sensors can also measure the thickness of non-conductive materials. Examples include glass, sapphire, and plastics, as well as semi-insulating semiconductor materials such as GaAs and silicon nitride. Analog vs. Digital Technologies MTI Instruments, a global supplier of precision measurement technologies, takes the guesswork out of what used to be a complex measurement for non-conductive materials. MTI's Digital Accumeasure system features a [...]

Capacitance Sensing Provides Two Ways to Measure EV Battery Plate Thickness

MTI Instruments has released an application note that explains how to use capacitance to measure the thickness of the lithium battery plates in electric vehicles (EVs). Manufacturers need to check these plates for thickness before calendaring them together to ensure that the overall battery diameter is within specifications. In EV batteries, lithium ion compounds are applied to either a copper plate substrate (cathode) or an aluminum substrate (anode plate). These conductive plates are separated by a dielectric. MTI Instruments, a global supplier of precision measurement solutions, makes capacitance sensors that can measure thicknesses materials down to nanometers. Moreover, MTI [...]

Trends in High Resolution Sensors for Semiconductor Metrology and Inspection

High resolution sensors are supporting improvements in semiconductor metrology and inspection at vital points in the production process. Because the fabrication of semiconductor wafers may require hundreds of steps and weeks of manufacturing time, early-stage defects that go undetected can have costly downstream consequences. Plus, because semiconductor processing always requires a high degree of precision, advances in fabrication methods seem to require ever-finer measurements in a never-ending quest. Today’s metrology instruments are incorporating high resolution sensors for automated wafer inspection. Resolution, the smallest measurement that a sensor can reliably indicate, may be given in dimensional units such as nanometers [...]