Blogs

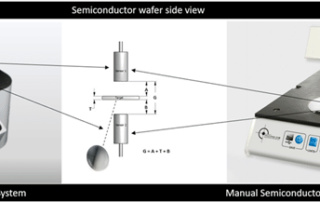

Why Disc Geometry Matters In Wafer Production

This is the first of three articles in Semiconductor Wafer Measurement for Increased Profitability. The second article examines the cost of failing to inspect semiconductor wafers. The third article describes the benefits of using semi-automated, fully-automated, and manual systems for wafer metrology and inspection. Semiconductor wafers are cut from cylindrical silicon crystals, or ingots. The flatness of these disc-shaped wafers is controlled to tight tolerances to ensure that the entire wafer surface is suitable for integrated circuit (IC) production. If disc geometry is out-of-spec after cutting, it may be possible to reprocess the wafer. Cutting is only the first [...]

1520 Portable Signal Simulator

Laboratory grade accuracy, WiFi connectivity, Ruggedly built. Request a Quote Download Brochure Get proven reliability, performance, and remote operation in a portable signal simulator for testing and calibrating sensor-driven systems. The 1520 Precision Signal Simulator is a NIST-traceable signal source for testing and calibrating sensor-driven systems. This portable and easy-to-use system lets technicians bring laboratory-grade precision into the field or onto the factory floor or flightline. Applications include accelerometers, flow meters, pressure transducers, tachometer generators, and microphones. An intelligent sensor database lets operators simulate a wide variety of sensor types and build custom simulations [...]

How Capacitive Measurement Can Help Reduce Packaging Waste

Product packaging is often made of lightweight polymeric foams or plastic sheets and films. These materials are relatively inexpensive, but manufacturers still want to minimize waste and maximize yields. Across high volumes of low-cost materials, even a small per-unit savings can become significant, especially as the price of petroleum – a key ingredient in many polymers – continues to rise. For companies with environmental sustainability efforts, there are other important considerations as well. The excessive use of packaging materials can contribute to environmental pollution, especially with polymers that are slow to degrade. Yet, materials such as plastic sheets and [...]

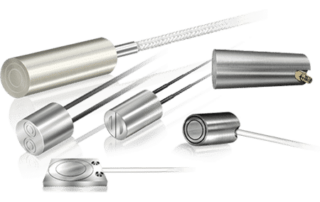

Non-Contact Displacement Sensors for Detection and Measurement

Non-contact sensors detect or measure a physical property without making direct contact with the target, the object that is being monitored or measured. They are used to measure physical properties such as thickness, proximity, displacement, or distance. To obtain readings, non-contact displacement sensors emit a form of energy and may use capacitance, fiber optic, or laser triangulation technologies. By contrast, contact sensors must touch the target and often rely upon mechanical movement. Non-Contact Sensors vs. Contact Sensors Non-contact sensors are faster, especially for applications with high sampling rates, and won’t dampen the motion of a target. They can also [...]

Advantages of Measuring Semiconductor Thin Film Thickness with Capacitance

Semiconductor Thin Films: Measuring Thickness with Capacitance In the semiconductor industry, thin films are deposited onto silicon and other wafer materials one atomic layer at a time. The thickness of these extremely thin coatings is important because thin-film thickness affects the wafer’s electrical, optical, and mechanical properties. With semiconductors, either conductive metallic films or non-conductive metal oxide films are deposited. There are two main thin-film coating methods, chemical vapor deposition (CVD) and physical vapor deposition (PVD), both of which use a variety of processes. Because the coatings for semiconductor wafers are so thin, thickness measurement require a high degree [...]

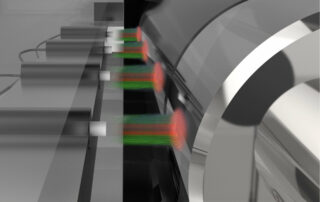

Laser Measurement Solutions

Laser Measurement Solutions Request Quote Providing precise, high-resolution gap, thickness, distance and displacement laser measurement solutions for the semiconductor, automotive, aviation, electronics, and medical industries, our products are relied on globally, in a wide range of environmental conditions and configurations. Delivering over 60 years of expertise and industry authority to ensure the right solution for your needs From laser product solutions that can be integrated into your manufacturing process to a stand alone system, we’ll help you find the right solution for your needs. Ensuring you have the right product solution to meet measurement and [...]

Contact vs. Non-Contact Measurement and Linear Displacement Sensors

Contact vs. Non-Contact Measurement and Linear Displacement Sensors Linear displacement sensors are used to measure the distance between two points or two plane surfaces. They use various technologies, but there are two basic types: contact and non-contact. As their names suggest, contact sensors make physical contact with the object that is being measured and non-contact sensors do not. This is an obvious but important difference, but there is much more to consider. Non-contact measurement is faster than contact measurement, especially for applications with high sampling rates. Because contact-type devices must touch and then traverse the object, measurement is slower. [...]

Capacitance Sensors vs. Eddy Current Sensors Application Note

Capacitance Sensors vs. Eddy Current Sensors Application Note Capacitance sensors and Eddy current sensors are both used for non-contact measurements. Capacitive probes use electric fields to measure the distance from the sensor face to the surface of a target that is typically conductive and grounded. Eddy current probes use an alternating AC current to induce a magnetic field in a conductive target instead. In turn, the induced magnetic field produces a back magnetic field that is proportional to the gap between the probe face and the target. In a recent application note, MTI Instruments examines the differences between capacitance [...]

Foam Density Measurement: Capacitance Sensors vs. Nuclear Gauges

This application note from MTI Instruments compares two technologies for measuring foam density: capacitance sensors and nuclear gauges. It examines the basic operating principles of each technology and explains why capacitance measurement is recommended for in-line measurement during foam manufacturing. Capacitance Sensors Capacitive probes are non-contact devices that use electric fields to measure foam density. In combination with a thickness value, a density measurement may be calculated. These probes consist of a capacitance sensor inside of a protective housing and are part of a larger measurement system that includes amplifiers, cables, and software. With parallel plate capacitance, the capacitance probe [...]

Capacitance Sensing vs. Strain Gauge Sensing Application Note

Capacitance Sensing vs. Strain Gauge Sensing Application Note Capacitance probes that are embedded in piezo flexure stages can provide significantly greater accuracy than strain gauges. Although some minor mounting modifications are required, capacitance probes with picoscale positioning provide higher linearity, greater long-term stability, and better direct measurement. Capacitance sensors cost more, however, and are limited by sensing distance. Therefore, strain gauge sensors remain a good choice for applications where cost is a consideration, sensing distances are larger, and high resolution or high accuracy are required. In a recent application note, MTI Instruments examines the differences between capacitance probes and [...]