Blogs

CEMENT BOARD QUALITY CONTROL

Cement backer board is used as underlayment for tile floors, walls and counter tops. It is also used as exterior sheathing and in exterior stucco systems. Cement backer board has proven to be more durable than virtually any other underlayment if quality control and thickness is maintained. The Problem: A major cement board manufacturer was faced with the challenge to improve a board production line throughput and decrease the amount of waste in the process. Too thin of cement board material weakens it structurally, while board that is too thick wastes material and resources, as well as drives up production costs. [...]

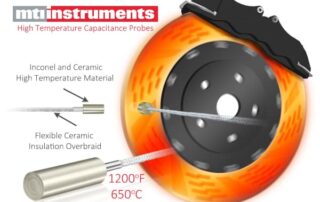

Measuring Brake Rotor Thickness Variation with Capacitive Sensing

Brake rotor thickness variation, or disc thickness variation (DTV), causes uneven wear to brake rotors, disc-shaped automotive parts that are squeezed between brake pads to slow or stop a vehicle’s wheels. When a brake rotor has areas of different thickness, the amount of clamping force that’s applied across the rotor’s surface varies. These differences in clamping force lead to difference in torque, and the results may include brake shuddering, pulsating, or vibration. Even under normal driving conditions, brake rotors are subjected to extreme conditions that can cause performance-related issues. To ensure that brake rotors can perform properly without problems such [...]

Measurements Using Capacitive Sensors

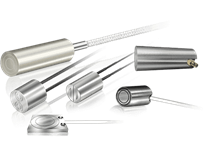

Capacitive sensors can be divided into two categories based upon their performance and intended use. High resolution sensors are typically used in displacement and position monitoring applications where high accuracy, stability and low temperature drift are required. Quite frequently these sensors are used in process monitoring and closed-loop feedback control systems. Proximity type capacitive sensors are much less expensive and are typically used to detect the presence of a part or used in counting applications. Applications Position Sensing General positioning is probably the most common application for capacitive sensors. As mentioned about, [...]

Measurement Applications

Measurement Applications Application Notes by Measurement Type Whatever our customers are trying to measure precisely, MTI Instruments has a tool. From getting accurate distances and thicknesses to precise vibration analysis, our measurement systems and tools are used by industry leaders around the world. Take a look at the measurement types below to see the variety of tools we have for various applications that help our customers.

Laser Triangulation Sensor Principles

Laser triangulation sensors can be divided into two categories based upon their performance and intended use. High-resolution lasers are typically used in displacement and position monitoring applications where high accuracy, stability and low temperature drift are required. Quite frequently these laser sensors are used in process monitoring and closed-loop feedback control systems. Proximity type laser triangulation sensors are much less expensive and are typically used to detect the presence of a part, or used in counting applications. Laser Triangulation Sensor Applications Position Sensing General positioning is the [...]

Advanced Sensing & Physical Measurement Technology Principles

Overview At MTI Instruments, we offer advanced sensing and physical measurement technology in products that range from basic sensors to complete, fully integrated measurement systems. The technologies we bring to bear to solve measurement applications include capacitance, laser and fiber-optic sensors, which can provide resolution up to 0.01 uin. (2.5 Angstroms). Sensors are available for integration into existing systems or as a complete system level solution Our technologies are available as sensors for integration into existing data acquisition systems or as complete system-level solutions that can be further integrated into a facility wide communication backbone. [...]

Measurements Using Capacitive Sensors

Precise Measurements Using Capacitive Sensors Capacitive sensors can be divided into two categories based upon their performance and intended use. High resolution sensors are typically used in displacement and position monitoring applications where high accuracy, stability and low temperature drift are required. Quite frequently these sensors are used in process monitoring and closed-loop feedback control systems. Proximity type capacitive sensors are much less expensive and are typically used to detect the presence of a part or used in counting applications. Applications Position Sensing General positioning is probably the most [...]

TSC-4800A: Tachometer Signal Conditioner System

TSC-4800A: Tachometer Signal Conditioner System Programmable tachometer conditioner for engine monitoring and testing systems The state of the art speed resolver/signal conditioning unit capable of working with all types of engine speed signals. Whether you are testing engines with a long tooth or short tooth embedded N1 signal, if you have engines with older high-voltage tachometer generators, or if you are testing engines with the new offset tooth design, the TSC-4800A will condition all of these types of signals. Download Brochure About TSC-4800A Tachometer Signal Conditioner SystemProgrammable tachometer conditioner for [...]

Laser Thickness Gauge System Principles

Microtrak™ 3 TGS The Microtrak™ 3 TGS system is specifically designed for thickness applications utilizing two lasers. The product can be used in a standalone configuration or easily interfaced with PLCs and PCs. Each module contains an integral LCD display and keypad for setup and display of measurements. A USB serial port also allows control by a laptop computer. Basic PLC or control input/output is provided by discrete digital I/O lines or a Modbus® interface. Laser Triangulation Principle The Microtrak™ 3 TGS system uses the principle of laser triangulation to perform a one dimensional [...]

Download How to Reduce Inconsistent Wafer Measurements

How to Reduce Inconsistent Wafer Measurements Thank you for downloading! Here's the link to How to Reduce Inconsistent Wafer Measurements.