Blogs

3D Integrated Circuits Use Capacitive Sensing to Ensure Coplanarity

Three-dimensional (3D) integrated circuits (ICs) feature silicon wafers and dies that are stacked vertically for improved device performance. By using the Z-axis, 3D ICs can overcome the power and footprint limitations associated with two-dimensional (2D) integrated circuits. Yet 3D ICs need coplanar surfaces to contact all of the pads, pins, and pillars. To determine coplanarity, semiconductor manufacturers measure the angle and gap between two planes. Bonding tool actuators use these measurements to adjust components and ensure that all device pins and solder balls reside on the same geometric plane. This process, active parallelism compensation, promotes proper bonding without residual [...]

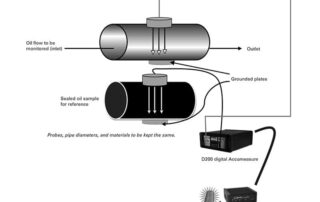

Oiling System Uses Capacitive Sensing to Detect Water Contamination

Water contamination can reduce the life of lubricants and increase the frequency of maintenance and repairs. If corrective action isn’t taken before an out-of-limit incident occurs, operational costs can escalate. When unplanned maintenance disrupts operations, productivity suffers and technicians may focus on a quick fix instead of the root cause. To detect water contamination in oil systems, in-line capacitance probes can be used. These flexible, off-the-shelf devices provide automatic and continuous monitoring. Yet checking moisture levels isn’t just about enhancing reliability or eliminating corrosion. In-line capacitance probes improve operations by supporting a proactive approach to maintenance. How In-Line Capacitance Probes [...]

The Top Five Trends Impacting Test and Measurement for 2019

With 2019 upon us, we know everyone is thinking about what's next in the Test and Measurement industry. We also know that without test and measurement equipment, engineers can't accurately and consistently prove that their mechanical or electronic devices perform as required. When they don't work, engineers also need to determine why and how to fix them. All of this leads to innovative thinking on how to test and measure even better by taking advantage of rapidly growing trends such as digitization, software, additive manufacturing, the Internet of Things (IoT), and new sensing applications that are driving advances in T&M. [...]

Offshore Wind Supply Chain Uses MTI Capacitance Sensors

Capacitance sensors from MTI Instruments are an important part of the supply chain for offshore wind (OSW) in New York State. According to a recent report from the Center for Economic Growth (CEG), New York’s Capital Region is home to MTI Instruments and dozens of other manufacturers who support this growing form of wind power. The Capital Region also offers essential infrastructure for OSW. As the CEG report explains, the New York State Energy Research Development Authority (NYSERDA) has assessed 54 waterfront sites for OSW-related projects such as component staging, manufacturing, and fabrication. Two of the most promising sites [...]

About Wafer Bow And Warp Measurement Systems

Semiconductor/Solar Wafer Bow And Warp Metrology/Surface About Wafer Bow And Warp Measurement Systems Thickness Measurement for Metrology Systems ASTM F657: The distance through a wafer between corresponding points on the front and back surface. Thickness is expressed in microns or mils (thousandths of an inch). Total Thickness Variation (TTV) ASTM F657: The difference between the maximum and minimum values of thickness encountered during a scan pattern or series of point measurements. TTV is expressed in microns or mils (thousandths of an inch). Figure above shows a wafer placed between two non-contact [...]

THICKNESS INFORMATION OF COMPOSITE MATERIALS

Composite materials consist of two or more materials which include a substrate or base material such as paper, cotton cloth, or glass cloth along with a resin or adhesive such as epoxy, melamine, or silicone. To make a thermoset laminate, the base material is coated with the adhesive so that layers of material can be pressed under heat and pressure into sheet form. The Problem: Composite material thickness needed to be verified prior to forming or machining. Due to the size of the sheets typical measurement techniques were not suitable. A consistent method to accurately measure the board thickness [...]

TORQUE CONVERTER

Industry Automotive Applications Torque Converter Measurement Type Surface Description Since minute defects in the torque converter casing wall thickness can result in unacceptable and dangerous torque converter expansion, a precision measurement system was needed to measure the impeller hub displacement and thus the torque converter axial displacement. An AC dynamometer would be required to spin the torque converter at a high rate of speed while a fast response hydraulic system is needed to pressurize the converter to pressures up to 150 psi. MTI’s MicroTrak laser sensor was selected because it offered [...]

Modernizing a Passive Sonar that has a Beam-Former with Digital Output

Modernizing a Passive Sonar that has a Beam-Former with Digital Output Customer Case The customer's requirement is to capture 10 signals, lasting 0.6 milliseconds each. 120 such signals arrive sequentially from a multiplexer within a beam-former. The clock rate is 2 MHz. The beam-former creates 120 beams and the raw digital data (underwater acoustic signal) from each beam is present at the output port of beam-former with a clock rate of 2 Mhz. At a certain time, we get the digital raw data of one beam. We plan to get 120 x 10 12-bit data records. That is, we [...]

Intra-Vascular Ultrasound

Intra-Vascular Ultrasound Customer Case The customer does intra-vascular diagnostic ultrasound. In this novel technique, an ultrasonic catheter is guided through a patient's blood vessel. Throughout its helical or corkscrew-like path, the ultrasonic transducer-tipped catheter emits bursts of ultrasonic energy. Reflections from the vessel wall return into the transducer and can be used to characterize such features as plaque deposits. The customer wishes to resolve features as small as 3 mm. The amount of time, D t, required for ultrasound to reflect off an interface that is a distance x away and return to the transducer is: D t = [...]

Measurement Applications

Measurement Applications Application Notes by Measurement Type Whatever our customers are trying to measure precisely, MTI Instruments has a tool. From getting accurate distances and thicknesses to precise vibration analysis, our measurement systems and tools are used by industry leaders around the world. Take a look at the measurement types below to see the variety of tools we have for various applications that help our customers.