Blogs

Hopkinson Bar Testing (Stress Pulse Reaction Testing)

Hopkinson Bar Testing (Stress Pulse Reaction Testing) Customer Case This customer is involved in testing materials for how they react to stress pulses. The idea is to introduce a stress pulse into the Material Under Test (MUT) and monitor it as it travels through the material. This method of material characterization is also known as "Hopkinson Bar" testing. Multiple sensors pick up the reaction of the material and provide outputs which need to be digitized. These outputs are transient signals of approximately 2 Volts and have a rise time of approximately 600 nanoseconds. The resulting system must be programmable [...]

EV Batteries Need Thickness Gauging for Lower Costs and Higher Performance

EV batteries need to cost less and last longer. Until the e-mobility industry solves these challenges, electric vehicle (EV) adoption won’t match the hype that’s driven by Tesla, the established automakers, and a host of startups who are attracting investors. According to Axios, the expense of owning an electric vehicle will exceed that of owning a conventional one until EV batteries cost less than $100/KWh to produce. Unfortunately, the EV industry isn’t expected to hit that target for another ten years. Yet, there is some encouraging news. Less expensive and better performing EV batteries are just a few years [...]

Vibration Test Equipment Instrument Grade Chassis

Vibration Test Equipment Instrument Grade Chassis Customer Case The customer is in the business of building Vibration Test equipment for semiconductor, automotive and aerospace industries. Their product is currently housed in Industrial Grade PCs which they integrate themselves. They currently purchase the chassis from an off-shore company. Their major problem is product differentiation: their product looks like "just another PC" and, therefore, cannot command a better price point. They also presently have to ship a separate monitor, as one is not integrated in the chassis. They want to upgrade the chassis to one of better quality, with a more [...]

Check Out Vitrek’s Available Education and Product Training Resources

At Vitrek, we do more than just design and build high-quality electrical testing equipment — we ensure that our customers have all of the tools that they need to succeed when using our products. Here, we offer an overview of the plethora of educational resources that we have available on our website. […]

High Resolution Semiconductor Wafer Measurements at Lower Costs

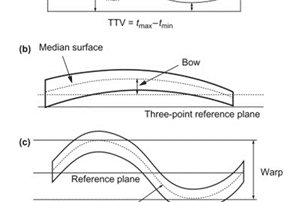

MTI's Proforma technology characterizes semiconductor wafers in terms of bow and warp, thickness, total thickness variation (TTV) and center thickness. Until recently, semiconductor wafer measurements at resolutions less than 100 µm were cost-prohibitive. Moreover, only expensive devices such as interferometers were capable of these measurements. Today, the semiconductor industry can use capacitance gauges instead of laser interferometers to achieve high resolution at fraction of the cost. Much like affordable CCD cameras transformed and expanded the market for video, cost-effective capacitance is disrupting the semiconductor wafer measurement market and creating new opportunities for quality testing and validation. The [...]

Measure Wafer Bow, Warp and TTV with Capacitance

The flatness of silicon wafers used to manufacture integrated circuits is controlled to tight tolerances to help ensure that the whole wafer is sufficiently flat for lithographic processing. To ensure your wafer manufacturing process is within tolerance, you need to measure the wafers being produced. Various measurement techniques exist to verify process tolerances and eliminate expensive scrap wafers. Non-contact capacitive sensing is a highly precise and cost-effective means to measure wafer flatness, bow, warp, and total thickness variation (TTV). MTI Instruments’ Proforma 300i and 300iSA systems use capacitance sensors to improve yields while reducing costs through better dimensional control of [...]

How to Measure Dielectric Separator Thickness in EV Batteries

The International Energy Agency predicts that as many as 125 million electric vehicles (EVs) will be on the road by 2030. At the heart of these electric cars, trucks, and buses is the lithium-ion (Li-ion) battery, a type of rechargeable battery with high energy density and low self-discharge. The plates in Li-ion batteries consist of lithium compounds that are applied to either a copper plate substrate (cathode) or an aluminum substrate (anode). In turn, these two plates are separated by a dielectric separator. All of the layers in an EV battery are extremely thin. In fact, the cathode and [...]

Capacitance Sensing for Non-Contact Thickness Measurements of Insulating Materials

Capacitance sensing can be used to make non-contact thickness measurements for most insulating materials. Capacitance sensors are known for their ability to precisely measure the thickness and position of conductive targets, but what’s less known is that these sensors can also measure the thickness of non-conductive materials. Examples include glass, sapphire, and plastics, as well as semi-insulating semiconductor materials such as GaAs and silicon nitride. Analog vs. Digital Technologies MTI Instruments, a global supplier of precision measurement technologies, takes the guesswork out of what used to be a complex measurement for non-conductive materials. MTI's Digital Accumeasure system features a [...]

SEPTA Case Study: Major Metropolitan Transit System Uses Vitrek Power Analyzer to Monitor High-Power DC Feeders

- - - Challenges Personnel needed a reliable, portable instrument to accurately measure and record the current on each feeder over a selected time period. - Overview The Southeastern Pennsylvania Transportation Authority (SEPTA) operates the transit system throughout the city of Philadelphia, extending into the surrounding counties in Pennsylvania and across the Delaware River into New Jersey. A major component of this system is the network of subways and commuter trains. Power for the operation of these trains is provided by an array of substations distributed throughout the region. One [...]

Machine Tools Characterization

Machine Tools Characterization Customer Case This customer is involved in characterizing machine tools. In order to do this, they need five simultaneous channels capturing 12-bit samples at 50 KSPS, with a 20 us sample width. A total of 5 seconds of data is required. GaGe Case Solution The solution to this problem is a three-card Master/Slave CompuScope 512 system, with each card having 512 Kilosamples of on-board memory. The CompuScope 512 is a 12-bit 5 MSPS A/D card for the ISA bus. As each CompuScope 512 has two channels, this system would provide 6 channels for the customer's application. [...]