Blogs

Foam Density Measurement: Capacitance Sensors vs. Nuclear Gauges

This application note from MTI Instruments compares two technologies for measuring foam density: capacitance sensors and nuclear gauges. It examines the basic operating principles of each technology and explains why capacitance measurement is recommended for in-line measurement during foam manufacturing. Capacitance Sensors Capacitive probes are non-contact devices that use electric fields to measure foam density. In combination with a thickness value, a density measurement may be calculated. These probes consist of a capacitance sensor inside of a protective housing and are part of a larger measurement system that includes amplifiers, cables, and software. With parallel plate capacitance, the capacitance probe [...]

Get More Out Of Your Military & Aerospace Applications

When testing the electrical systems for your military and aerospace applications, you need to ensure they are ready for the job and meet all the necessary standards. These specialized systems work to keep the highly sophisticated and advanced technology housed in these applications running at full strength, which requires the right amount of power to do their jobs effectively. Having the right electrical safety and performance testing equipment on hand can help determine the overall effectiveness of your applications. […]

Ultrasonic Tissue Characterization

Ultrasonic Tissue Characterization Customer Case This customer's application is Ultrasonic Tissue Characterization. Their ultrasonic sensors transmit 16 signals. The customer's requirement is to capture 512 points on the 16 channels, average them together, and then store the data in a buffer, with the system running continuously. They would like to be able to update the average buffer and recapture data as fast as possible. They would then like to log the data to disk or process the data and display an image on the screen. Since the signals coming in from their ultrasonic sensors are very weak, the customer [...]

White Paper: Hipot Testing of Military/Aerospace Interconnect Components

Introduction Operational performance and safety are paramount concerns when determining the acceptability of a range of interconnection products in military and aerospace applications. Connectors and relays, wires, wire bundled into cables and harnesses, all must be tested against stringent standards. The number and range of these standards is mind-numbing — and this paper makes no attempt to catalog them all. Rather, notable and salient MIL standards and similar aerospace standards will be used to site the key role that high-performance electrical safety testers, ancillary equipment and software play in effecting reliable and cost-effective compliance testing of components as [...]

Webinar Recap: Vitrek Products for Metrology and Calibration Labs

Metrology requires equipment capable of precise measurements and accurate readings. Taking the time to ensure that the instruments you use remain properly calibrated requires the right tools and training to ensure that they are in good working order. In our webinar: Vitrek Products for Metrology and Calibration Labs, we cover why you need the right calibration tools and why Vitrek offers the best high voltage tester options on the market in the form of our 4700 High Voltage Meter, PA920 Power Analyzer, and 2000MN Calibrator. […]

Using Capacitance Sensors for Non-Conductive Material Measurement

Non-Conductive Material Measurement with Capacitance Sensors Capacitance sensors are non-contact devices that can be used to obtain position, thickness, and dynamic measurements with a high degree of precision, accuracy, and resolution. Capacitive measurement is used with electrically-conductive materials such as metals but can also be used to measure non-conductive materials such as glass, sapphire, and many plastics. Even if a non-conductive material is relatively inexpensive (such as closed cell foam), manufacturers want to avoid errors that can result in significant waste across high volumes. Importantly, capacitance measurement is also used with semi-insulating materials such as gallium arsenide (GaAs) and [...]

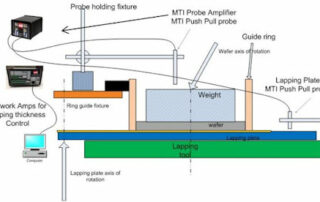

Semiconductor Wafer Lapping and Displacement Measurement

Semiconductor Wafer Lapping and Displacement Measurement Semiconductor Semiconductor Wafer Manufacturing Displacement Description Semiconductor Wafer Lapping and Displacement Measurement This application note explains how MTI’s Accumeasure technology was used with a lapping machine to measure displacement (wafer material removal) and determine the new semiconductor wafer thickness. Changes in electrical capacitance (displacement) were measured and then directly converted into a 24-bit digital reading to obtain precise digital thickness measurements. During lapping, a wafer of known start thickness is placed on a rotary lapping table. The backside of the wafer faces downward and [...]

Why Demand for SiC Wafers is Hot and Durable

Why Demand for SiC Wafers is Hot and Durable Pardon the pun, but SiC wafers are a hot item for high-temperature applications. Silicone carbide (SiC), a semiconductor containing both silicon and carbide, withstands temperatures up to 2700°C. Carborundum, as this durable ceramic is also known, finds additional applications in bulletproof vests, extrusion dies, sandpaper, and high-performance disc brakes. In electronics, SiC materials are used with light-emitting diodes (LEDs) and detectors. In the semiconductor industry, a market where interest is red-hot, SiC wafers are used in electronic devices that operate at high temperatures, high voltages, or both. Examples include electric [...]

Wafer Stress Analysis Using the 300iSA

Wafer Stress Analysis Using MTI Instruments Proforma 300iSAWafer processing involves several stages that may translate into mechanical alterations. Sometimes these alterations can cause deformities that render the wafer either unusable or that put it marginally close to not being usable. To determine this, stress analysis can be used.The Proforma 300iSA wafer characterization tool provides a software capability in which a wafer can be analyzed prior to processing and then after processing. The tool then evaluates how the wafer changed and hence, provides the resulting stress analysis.The software expects the customer to provide the material elasticity constants and to define them [...]

Webinar Recap: Cable Testing Systems

For over thirty years, Vitrek has been a leading provider of high-quality, multi-functional electrical and high voltage testing equipment. Based in San Diego, CA, Vitrek is an internationally recognized electrical and safety test equipment manufacturer supplying customers in 30 countries. Vitrek designs and manufactures cutting-edge test equipment used in industries such as aerospace, military, medical, automotive, and many more! […]