Blogs

Measuring Glass wafer thickness with a Proforma 300i

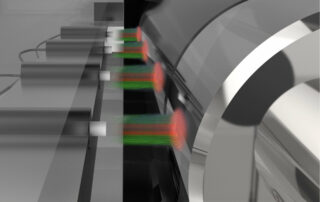

Measuring glass substrate thickness with a Proforma 300i Semiconductor Glass Wafer Thickness Measurement Thickness Applications testing of glass (substrate) thickness An applications experiment was made with the MTI Proforma 300i Semiconductor thickness system to determine if it’s useful to measure glass substrate thicknesses typically found as support structures for Si semiconductors that are used for fabricating MEMs components and other thin Si wafers. The MEMs Silicon wafer is so thin after grinding that it needs the support of a thicker substrate to prevent breakage of the wafer during the back grinding/thinning [...]

MTI Instruments Enters Advanced Qualification Stage for Electric Vehicle Battery Measurement Device with Several Major Automotive OEM Manufacturers

NEW YORK, December 16, 2021 – MTI Instruments division, a manufacturer of precision tools and testing equipment for electronics, aviation, automotive, power and other industries, today announced that it has entered into the advanced qualification stage for its electric vehicle (EV) battery measurement device with several major automotive OEM manufacturers. Moshe Binyamin, President and CEO of MTI Instruments commented, “We committed to shareholders that we would communicate with them as we began to get traction in the growing and large EV Battery manufacturing segment. I am pleased to report, we are gaining serious traction.” Binyamin further added, “In fact, [...]

MTI Instruments Announces Record $1.4 Million Order with Global Industrial Manufacturer

NEW YORK, Dec. 15, 2021 (GLOBE NEWSWIRE) -- via NewMediaWire -- MTI Instruments division, a manufacturer of precision tools and testing equipment for electronics, aviation, automotive, power and other industries, today announced a $1.4 million order with a global industrial manufacturer. The contract also includes a 14-year ongoing maintenance and support component representing another high-value contract win with recurring revenue. This repeat order stems from a multi-year customer relationship and is for MTI’s Block Gage measurement device that allows this top-tier global industrial manufacturer to perfectly machine ball pistons that require extremely precise accuracy for high power transmissions. MTI uses [...]

Exploring the Different Types of Aircraft Vibrations

There are two main types of aircraft vibrations: normal and abnormal. Normal vibrations regularly occur when an airplane is in flight and during takeoff and landing. These oscillating or reciprocating motions do not indicate potential defects with the aircraft or its engines and can be explained by routine operations such as flying through turbulence or extending or retracting the landing gear. With abnormal vibrations, a mechanical defect or condition is to blame. If this is not corrected, further damage and even catastrophic failure may occur. What are the causes of aircraft vibrations? The causes of aircraft vibrations include: engine [...]

How Capacitive Measurement Can Help Reduce Packaging Waste

Product packaging is often made of lightweight polymeric foams or plastic sheets and films. These materials are relatively inexpensive, but manufacturers still want to minimize waste and maximize yields. Across high volumes of low-cost materials, even a small per-unit savings can become significant, especially as the price of petroleum – a key ingredient in many polymers – continues to rise. For companies with environmental sustainability efforts, there are other important considerations as well. The excessive use of packaging materials can contribute to environmental pollution, especially with polymers that are slow to degrade. Yet, materials such as plastic sheets and [...]

Non-Contact Displacement Sensors for Detection and Measurement

Non-contact sensors detect or measure a physical property without making direct contact with the target, the object that is being monitored or measured. They are used to measure physical properties such as thickness, proximity, displacement, or distance. To obtain readings, non-contact displacement sensors emit a form of energy and may use capacitance, fiber optic, or laser triangulation technologies. By contrast, contact sensors must touch the target and often rely upon mechanical movement. Non-Contact Sensors vs. Contact Sensors Non-contact sensors are faster, especially for applications with high sampling rates, and won’t dampen the motion of a target. They can also [...]

Advantages of Measuring Semiconductor Thin Film Thickness with Capacitance

Semiconductor Thin Films: Measuring Thickness with Capacitance In the semiconductor industry, thin films are deposited onto silicon and other wafer materials one atomic layer at a time. The thickness of these extremely thin coatings is important because thin-film thickness affects the wafer’s electrical, optical, and mechanical properties. With semiconductors, either conductive metallic films or non-conductive metal oxide films are deposited. There are two main thin-film coating methods, chemical vapor deposition (CVD) and physical vapor deposition (PVD), both of which use a variety of processes. Because the coatings for semiconductor wafers are so thin, thickness measurement require a high degree [...]

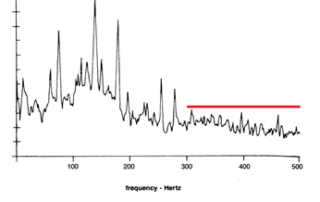

How Often Should Vibration Analysis Be Performed?

How Often Should Vibration Analysis Be Performed? Once a customer takes delivery of a PBS system and learns how to use it, the next logical question is: “How often should we use it?” At a minimum, your approved maintenance program (whether it’s a program developed by your operation, or the maintenance procedures outlined by the engine/airframe manufacturer) will tell you about the intervals at which to perform a vibration analysis. Usually, there is a procedure to specify how an engine vibration analysis and balance need be only completed when squawked by a pilot or after the completion of maintenance work [...]

Contact vs. Non-Contact Measurement and Linear Displacement Sensors

Contact vs. Non-Contact Measurement and Linear Displacement Sensors Linear displacement sensors are used to measure the distance between two points or two plane surfaces. They use various technologies, but there are two basic types: contact and non-contact. As their names suggest, contact sensors make physical contact with the object that is being measured and non-contact sensors do not. This is an obvious but important difference, but there is much more to consider. Non-contact measurement is faster than contact measurement, especially for applications with high sampling rates. Because contact-type devices must touch and then traverse the object, measurement is slower. [...]

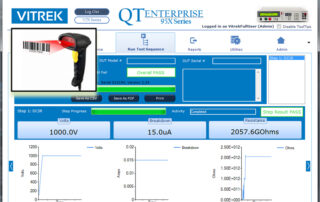

Press Release: Barcode Scanner Adds Functionality to Vitrek’s QT Enterprise Electrical Safety Testing Automation Software

Barcode Scanner Adds Functionality to Vitrek’s QT Enterprise Electrical Safety Testing Automation Software QT Enterprise software facilitates test sequence setup, report creation and data archiving; SQL database of test procedures and results accessible from multiple PCs; Barcode scanner input automatically loads and runs test sequences […]