Blogs

PIEZO STAGE POSITIONING

Industry Consumer Electronics Applications Piezo Stage Measurement Type Positioning Description Positioning stages using piezoelectric stack actuators (PEA) have very high resolution. However, it is difficult to achieve precise dynamic motion tracking using traditional linear controllers such as PID due to the inherent hysteresis nonlinearity of piezoelectric materials and the phase lag associated with such controllers. Capacitance Sensors are ideal for measuring the actual piezo stage position and correcting for the inherent nonlinearity through closed loop feedback. They have the stability, bandwidth and high resolution needed to do the job. [...]

Displacement Measurement by Fiber Optics

Displacement Measurement by Fiber Optics Semiconductor, Research & Development 3D IC Construction Displacement, Vibration Description The Fotonic™ Sensor is a non-contact instrument which uses the fiber optics lever¬π principle to perform displacement, vibration and surface-condition measurements (Figure 1). The Fotonic Sensor transmits a beam of light through a flexible fiber-optic probe, receives light reflected from a target surface, and converts it into an electrical signal proportional to the distance between the probe tip and the target being measured.¬† The output signal voltage from the fiber optic sensor is then used [...]

MicroTrak 4 Over a LAN for Ethernet Signaling

MicroTrak 4 Over a LAN for Ethernet Signaling Semiconductor, Research & Development 3D IC Construction Distance, Positioning, Displacement Description The MicroTrak 4, which is a USB device, can also be used over a LAN or even CAT 5e/6/7 wiring with additional hardware to convert the USB sensor to Ethernet signaling. The devices required to run over the LAN or direct CAT wire are Icron USB 2.0 Ranger 2301GE-LAN extender system. The MicroTtrak 4 basic software then runs on the host computer.  The LAN does not have to be dedicated; it [...]

Monitor Roller Gaps and Parallelism

Monitor Roller Gaps and Parallelism Industrial Printing, Calendering, Crushing Gap Easy Roller Gap Measurement Ensures Calendering Success Many roll-to-roll finishing processes typically use a calender, or series of hard pressure rollers, to deliver smooth, high-quality products of plastic, textile, or paper (Fig 1). Ensuring a consistent material thickness, however, depends on the ability to monitor, and maintain, a precise gap between rollers. This application note describes a quick and easy means for roller gap measurement. Figure 1: Calender Rollers where consistent gap across the rollers are vital [...]

GAAS SUBSTRATE THICKNESS MEASUREMENT

Industry Semiconductor Applications Gaas Substrate Thickness Measurement Measurement Type Thickness Description Measuring Thickness of Wafers with Different Chemistries Introduction: Silicon wafers are ordinarily highly conductive and easy to measure with standard capacitive displacement sensors (See MTI’s Proforma 300i). Measuring the thickness of GaAs wafers that have high bulk resistivity (>10k Ohm/cm) is a little more difficult because the wafers act as non-conductive insulators in a capacitive sensor’s measuring field. Fortunately, MTI has a solution to this problem. Solution: It’s possible to measure the thickness and TTV of high resistivity semiconducting wafers (like GaAs) using non-contact capacitive [...]

Capacitance Probes Measure Gaps in Rotating Environments

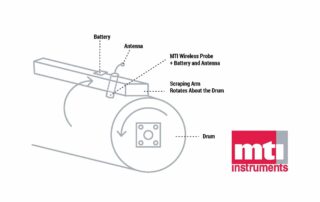

Capacitance Probes Measure Gaps in Rotating Environments Textiles, Industrial Optimizing Performance of Rotating Cylinders Gap Description [Application Note 72518] Sensor environments are not always ideal. Across the various Gap sensor applications conditions may vary drastically. Some setups may have requirements of miniaturization, and others of wireless signal propagation. In rotating environments where cables cannot go, often there is a need for both. Problem Traditional sensing solutions can’t be used in environments requiring wireless propagation such as inside a rotating body. In these situations, the size and power requirements restrict the [...]

SPINDLE RUN OUT

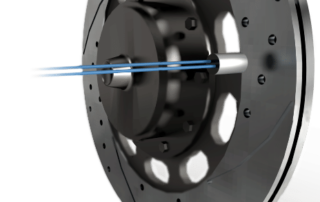

Industry Automotive Applications Spindle Run Out Measurement Type Positioning Description Rotating targets frequently have an intermittent, uncertain or nonexistent ground path. This introduces unwanted noise, instability, drift and reduces accuracy of the measurement. MTI Instruments offers a unique “Push-Pull” capacitance measurement system that does not require a grounded target. It utilizes two probes, built into one body, that work together to complete the ground path. One probe pushes current into the brake rotor while the adjacent probe pulls the current out. The result is a “clean”, consistent electrical sensing path. As [...]

CAPACITANCE SENSORS FACILITATE 3D IC CONSTRUCTION

[Application Note 70518] To boost device performance, today’s semiconductor and microelectronics manufacturers are building three-dimensional integrated circuits featuring vertically-stacked silicon wafers and dies. The rationale is simple. Exploiting the Z-axis avoids the power and footprint penalties associated with two-dimensional processes. Implementing the rationale, however, is not so simple. Going vertical requires coplanar surfaces to make contact with all pins, pads, and pillars. Problem Typically, manufacturers measure the angle and gap between two planes to determine coplanarity. Bonding tool actuators rely on these angle/gap measurements to adjust components and make sure all device pins and/or solder balls reside on the [...]

MONITOR ROLLER GAPS AND PARALLELISM

Easy Roller Gap Measurement Ensures Calendering Success Many roll-to-roll finishing processes typically use a calender, or series of hard pressure rollers, to deliver smooth, high-quality products of plastic, textile, or paper (Fig 1). Ensuring a consistent material thickness, however, depends on the ability to monitor, and maintain, a precise gap between rollers. This application note describes a quick and easy means for roller gap measurement. Problem Establishing a roller gap and checking for parallelism across roller width can be a slow and cumbersome procedure. Manual measurement requires multiple sized feeler gauges which can introduce errors. Misinterpreting feeler gauge drag, [...]

Windshield Manufacturing

Industry Automotive Applications Oil Film Measurement Type Level Description In order to maintain proper profile and thickness within a glass furnace the extrusion plate spacing must be maintained at a predetermined gap. Unfortunately, due to process changes and temperature swings this gap can fluctuate significantly in short periods of time. This variation causes the glass thickness to change (check out our glass thickness measurement devices to accurately measure thickness), producing uneven temperature gradients and creating potentially weak glass panels. To control this critical parameter the manufacturing process requires automated active feedback [...]