Blogs

High Resolution Semiconductor Wafer Measurements at Lower Costs

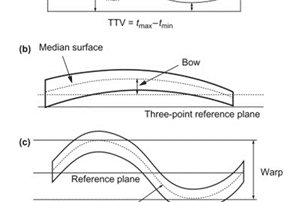

MTI's Proforma technology characterizes semiconductor wafers in terms of bow and warp, thickness, total thickness variation (TTV) and center thickness. Until recently, semiconductor wafer measurements at resolutions less than 100 µm were cost-prohibitive. Moreover, only expensive devices such as interferometers were capable of these measurements. Today, the semiconductor industry can use capacitance gauges instead of laser interferometers to achieve high resolution at fraction of the cost. Much like affordable CCD cameras transformed and expanded the market for video, cost-effective capacitance is disrupting the semiconductor wafer measurement market and creating new opportunities for quality testing and validation. The [...]

Measure Wafer Bow, Warp and TTV with Capacitance

The flatness of silicon wafers used to manufacture integrated circuits is controlled to tight tolerances to help ensure that the whole wafer is sufficiently flat for lithographic processing. To ensure your wafer manufacturing process is within tolerance, you need to measure the wafers being produced. Various measurement techniques exist to verify process tolerances and eliminate expensive scrap wafers. Non-contact capacitive sensing is a highly precise and cost-effective means to measure wafer flatness, bow, warp, and total thickness variation (TTV). MTI Instruments’ Proforma 300i and 300iSA systems use capacitance sensors to improve yields while reducing costs through better dimensional control of [...]

How to Measure Dielectric Separator Thickness in EV Batteries

The International Energy Agency predicts that as many as 125 million electric vehicles (EVs) will be on the road by 2030. At the heart of these electric cars, trucks, and buses is the lithium-ion (Li-ion) battery, a type of rechargeable battery with high energy density and low self-discharge. The plates in Li-ion batteries consist of lithium compounds that are applied to either a copper plate substrate (cathode) or an aluminum substrate (anode). In turn, these two plates are separated by a dielectric separator. All of the layers in an EV battery are extremely thin. In fact, the cathode and [...]

Capacitance Sensing for Non-Contact Thickness Measurements of Insulating Materials

Capacitance sensing can be used to make non-contact thickness measurements for most insulating materials. Capacitance sensors are known for their ability to precisely measure the thickness and position of conductive targets, but what’s less known is that these sensors can also measure the thickness of non-conductive materials. Examples include glass, sapphire, and plastics, as well as semi-insulating semiconductor materials such as GaAs and silicon nitride. Analog vs. Digital Technologies MTI Instruments, a global supplier of precision measurement technologies, takes the guesswork out of what used to be a complex measurement for non-conductive materials. MTI's Digital Accumeasure system features a [...]

Machine Tools Characterization

Machine Tools Characterization Customer Case This customer is involved in characterizing machine tools. In order to do this, they need five simultaneous channels capturing 12-bit samples at 50 KSPS, with a 20 us sample width. A total of 5 seconds of data is required. GaGe Case Solution The solution to this problem is a three-card Master/Slave CompuScope 512 system, with each card having 512 Kilosamples of on-board memory. The CompuScope 512 is a 12-bit 5 MSPS A/D card for the ISA bus. As each CompuScope 512 has two channels, this system would provide 6 channels for the customer's application. [...]

Capacitance Sensing Provides Two Ways to Measure EV Battery Plate Thickness

MTI Instruments has released an application note that explains how to use capacitance to measure the thickness of the lithium battery plates in electric vehicles (EVs). Manufacturers need to check these plates for thickness before calendaring them together to ensure that the overall battery diameter is within specifications. In EV batteries, lithium ion compounds are applied to either a copper plate substrate (cathode) or an aluminum substrate (anode plate). These conductive plates are separated by a dielectric. MTI Instruments, a global supplier of precision measurement solutions, makes capacitance sensors that can measure thicknesses materials down to nanometers. Moreover, MTI [...]

White Paper: Cable & Connector Test System Facilitates Multi-Point High Voltage/Current Testing

White Paper: Cable & Connector Test System Facilitates Multi-Point High Voltage/Current Testing Introduction Hipot testing is critical in assuring compliance with a host of electrical safety standards and in confirming the assembled product is free from electrical or mechanical defects. Hipot testers are used to measure leakage current and insulation resistance between all components and connections, confirm solid ground connections and test ground bonds. All of these tests require the sequential application of precise and controlled high voltages or currents between pairs of elements then accurately measuring and recording the results. Products like the Vitrek 95x and V7x series [...]

How Aviation MROs Can Maximize Labor Efficiency and Asset Uptime

MTI Instruments is supplying the aviation industry with solutions to the skilled labor shortage and reduced equipment availability. No, our Albany, New York company isn’t providing aviation MROs with more flight line personnel, engine mechanics, or Boeing 737 MAX aircraft. Instead, we’re delivering precision measurement solutions that can help MROs to maximize labor productivity and asset uptime. Solving the Skilled Labor Shortage Aviation MROs have a choice. They can wait for training programs to provide new workers, poach workers from competitors, invest in robots, or look for ways to gain greater efficiency from existing labor assets. About 18 months [...]

Microsoft Windows 7 Security Advisory and Impact on MTI PBS-4100+ Users

Learn about this important security advisory and its impact on MTI-PBS-4100+ users. What is the Microsoft Windows 7 Security Advisory? Microsoft will no longer provide maintenance on Windows Version 7 in January of this year after 10-years of supporting the product. Microsoft does this across their product lines (not just Windows) in order to continue to evolve their products and invest their resources on the more recent versions. This means that Microsoft will no longer release any updates for that version of Windows, including bug fixes or security updates. For details on this activity by Microsoft, please visit their [...]

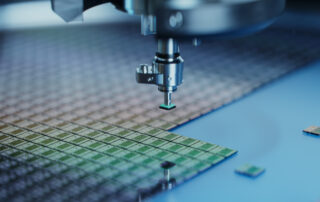

Trends in High Resolution Sensors for Semiconductor Metrology and Inspection

High resolution sensors are supporting improvements in semiconductor metrology and inspection at vital points in the production process. Because the fabrication of semiconductor wafers may require hundreds of steps and weeks of manufacturing time, early-stage defects that go undetected can have costly downstream consequences. Plus, because semiconductor processing always requires a high degree of precision, advances in fabrication methods seem to require ever-finer measurements in a never-ending quest. Today’s metrology instruments are incorporating high resolution sensors for automated wafer inspection. Resolution, the smallest measurement that a sensor can reliably indicate, may be given in dimensional units such as nanometers [...]