Blogs

Hopkinson Bar Testing (Stress Pulse Reaction Testing)

Hopkinson Bar Testing (Stress Pulse Reaction Testing) Customer Case This customer is involved in testing materials for how they react to stress pulses. The idea is to introduce a stress pulse into the Material Under Test (MUT) and monitor it as it travels through the material. This method of material characterization is also known as "Hopkinson Bar" testing. Multiple sensors pick up the reaction of the material and provide outputs which need to be digitized. These outputs are transient signals of approximately 2 Volts and have a rise time of approximately 600 nanoseconds. The resulting system must be programmable [...]

Vibration Test Equipment Instrument Grade Chassis

Vibration Test Equipment Instrument Grade Chassis Customer Case The customer is in the business of building Vibration Test equipment for semiconductor, automotive and aerospace industries. Their product is currently housed in Industrial Grade PCs which they integrate themselves. They currently purchase the chassis from an off-shore company. Their major problem is product differentiation: their product looks like "just another PC" and, therefore, cannot command a better price point. They also presently have to ship a separate monitor, as one is not integrated in the chassis. They want to upgrade the chassis to one of better quality, with a more [...]

Machine Tools Characterization

Machine Tools Characterization Customer Case This customer is involved in characterizing machine tools. In order to do this, they need five simultaneous channels capturing 12-bit samples at 50 KSPS, with a 20 us sample width. A total of 5 seconds of data is required. GaGe Case Solution The solution to this problem is a three-card Master/Slave CompuScope 512 system, with each card having 512 Kilosamples of on-board memory. The CompuScope 512 is a 12-bit 5 MSPS A/D card for the ISA bus. As each CompuScope 512 has two channels, this system would provide 6 channels for the customer's application. [...]

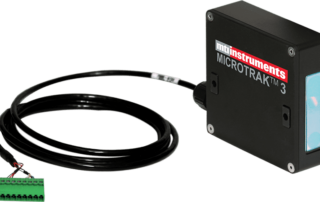

MICROTRAK 3: 1D Laser Displacement Sensor

An essential measurement tool for process automation, quality control and tool automation control. Request Quote Download Brochure Compact laser triangulation sensor head for easy integration to machine control system High resolution, high speed laser displacement sensor (non-contact linear displacement sensor) utilizes the latest CMOS sensor technology that challenges even the most difficult measurement applications. The Microtrak™ 3 is an essential measurement tool for process automation, quality control and tool automation control, for applications such as, thickness measurement, dimensional displacement, part profiling, vibrations testing, build-up measurement, and much more. Measurement rate [...]

MICROTRAK 4: 1D Laser Displacement Sensor

Accurate and repeatable displacement measurements from highly reflective to dull surfaces Request a Quote Download Microtrak 4 Brochure Compact digital laser displacement sensor head with stable and accurate measurements The latest 1D laser displacement sensor from MTI provides excellent speed and accuracy for even the most difficult applications and provides data output and power through a single USB cable. The MicroTrak 4 is the ultimate 1D laser sensor for measuring height, thickness, displacement, vibration, and more, with a sensor frame rate of 40k Samples/sec. and linearity of 0.03% FSO (Full Scale Output) accuracy and [...]

Fiber Optic Sensor Principles

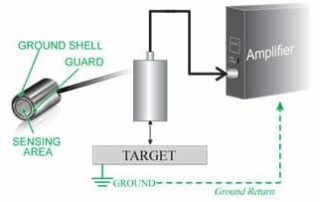

The Fotonic Sensor™ is a non-contact instrument, which uses the fiber optics lever principle to perform displacement measurement, vibration analysis and surface-condition measurements. The Fotonic Sensor transmits a beam of light through a flexible fiber-optic probe, receives light reflected from a target surface, and converts this light into an electrical signal proportional to the distance between the probe tip and the target being measured. A simplified example of the fiber optic principal is shown in Figure 2. The output signal voltage from the fiber optic sensor is then used to determine position, displacement, vibration amplitude, frequency and waveshape of a [...]

Common Test and Calibration Uses of the 1510A Portable Signal Generator

Introduction As one of the most versatile and powerful hand-held signal generators on the market, the 1510A is a two-channel, battery-powered, microprocessor-controlled direct digital signal generator. It has an average battery life of 3 hours of continuous use. Weighing in at under two pounds, makes it ideal for use in the field. There are many different ways this sophisticated device can be leveraged to perform precise test and calibration of equipment, wires, cables, sensors and much more. Use Case #1 | Sensor Simulation You can simulate sensors during system development, bring-up, and test. Often during [...]

Product Education & Training

Education & Training Vibration Measurement & Engine Rotor Balancing High-Speed Data Acquisition Products for Streaming Applications Industry Application Webinars Test & Measurement Solutions for Semiconductor Manufacturers GaGe Digitizers in Ultrasonic Applications Electrical Safety & Compliance Testing for Printed Circuit Board Manufacturers Vitrek Products for Metrologists & Calibration Labs Vitrek Electrical Safety Testing for the Appliance & Consumer Product Industries Compliance Testing for the Lighting Industry Webinar Vitrek [...]

Selecting a Displacement Sensor / Measuring System

Capacitive displacement sensors Capacitive displacement sensors are non-contact devices that are used for measurements at a high-resolution. It can also be used to check the position of any conductive object as well as measure the width or density of non-conductive materials. Capacitive displacement sensors have a large variety of uses including precision thickness measurements, assembly line testing, assembly metrology, and semiconductor processing. Capacitive displacement sensors can be found in manufacturing facilities all around the globe. There’s more to selecting the proper type of displacement sensor and measurement system than meets the eye. To select the appropriate type of device [...]

Target Material and Characteristics

Target Material and Characteristics Transparent/Opaque Targets There are a number of measurement systems that are capable of measuring a target that is opaque. When it comes to transparent targets, the measurement system being used must match the material of the target being measured. For example, if you’re attempting to measure plastic you should use a contact-type measurement system such as a micrometer. When performing a soft target measurement, such as film, a non-contact measurement system (such as a laser displacement sensor) should be utilized. Hard/Soft Targets Objects made out of hard material (such as a block of wood), would [...]