Blogs

MTI Application Note: Testing for Connector Failure Due To Vibration or Shock

Testing for Connector Failure Due to Vibration or Shock Mobile Communications Equipment Needs Reliable Connectors That Will Not Disconnect with Shock or Vibration Introduction A large multinational company approached MTI to provide a sensor capable of measuring displacement that also wouldn’t load the target (connector). Shock and vibration testing would span 2-15G and the target connectors were very small. Application MTI’s 2100 optical displacement sensor system is ideal for this kind of application because very small probes can be used and they measure displacement via reflected light. [...]

GaGe Whitepaper: Real-Time High-Speed Data Acquisition on PC-Based System Platforms

GaGe Whitepaper: Real-Time High-Speed Data Acquisition on PC-Based System Platforms By Gerald Allgaier, Systems Specialist and Bob Fitzgerald, Application Specialist - Vitrek For many measurements that require the capture and processing of analog data, data throughput speed and conversion resolution are the two most important considerations. Typical examples include Radar, Signals Intelligence (SIGINT), Ultrasound Imaging, Non- Destructive Testing (NDT), Mass Spectroscopy / Time-of-Flight (TOF), and Production Test. These test applications usually demand high speed data transfer rates. So typically, Digitizers (A/D) or Arbitrary Waveform Generators (D/A) residing on a high-speed backplane are required. These [...]

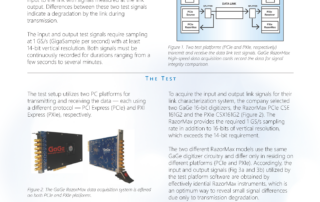

GaGe Application Note: Creating a Data Link Signal Integrity Test Platform

Download a PDF Copy of this App Note Data Link Device Testing The data link device under test (Figure 1) is characterized by comparing test signals that are input to the link with signals measured at the link output. Differences between these two test signals indicate a degradation by the link during transmission. Figure 1. Two test platforms (PCIe and PXIe, respectively) transmit and receive the data link test signals. GaGe RazorMax high-speed data acquisition cards record the data for signal integrity comparison. The input and output test signals require sampling at 1 GS/s (GigaSample per second) [...]

Cable Testing Applications

Cable Testing Applications Cable/Wire Testing Overview Cable testing is important in any industry that relies on cables for its operation. Cable testing is important for compliance and regulations because it helps ensure that cables meet the necessary requirements and standards set by regulatory bodies or industry organizations. These requirements are in place to promote safety, reliability, and performance, and failure to comply can result in legal consequences or penalties. Cable testing is important in various industries, including: Telecommunications: Cable testing is essential in the telecommunications industry to ensure that cables are properly installed and [...]

MTI’s Wireless Gap Measurement Probe System Is Ideal for Rotating Machinery

The Accumeasure capacitance probe system offers major improvement over conventional eddy current probes; network up to four probes per system to deliver rich geometrical in-situ measurements in a variety of industry standard formats. Albany, NY—June 28, 2022—MTI Instruments, a US-based manufacturer of advanced test and measurement equipment, announces the introduction of its Accumeasure Wireless Gap Measurement Probe System. The system consists of up to four, battery-powered, wireless capacitance probes paired via Bluetooth to their receiving device. The wireless capability and compact form factor of the battery-powered probes are designed specifically to measure gap in difficult-to-reach or [...]

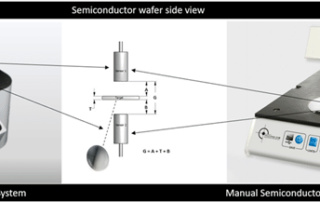

The Benefits of Manual, Semi-Automated, and Fully-Automated Systems for Semiconductor Wafer Inspection and Metrology

This is the third of three articles in Semiconductor Wafer Measurement for Increased Profitability. The first article in this series explains why disc geometry matters. The second article examines the cost of failing to inspect semiconductor wafers. Fully automated systems that can load, scan, and unload wafers are fast, convenient, and efficient at high volumes. They’re useful for checking every wafer in every batch, but these systems are expensive. Semi-automated and manual systems cost significantly less and are generally used for lower volumes; however, they’re also easy-to-use and can make fast, accurate measurements that support production flow. Semi-automated and [...]

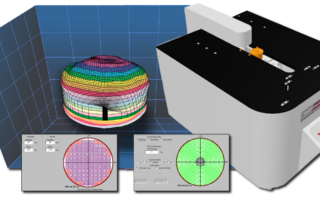

Why Disc Geometry Matters In Wafer Production

This is the first of three articles in Semiconductor Wafer Measurement for Increased Profitability. The second article examines the cost of failing to inspect semiconductor wafers. The third article describes the benefits of using semi-automated, fully-automated, and manual systems for wafer metrology and inspection. Semiconductor wafers are cut from cylindrical silicon crystals, or ingots. The flatness of these disc-shaped wafers is controlled to tight tolerances to ensure that the entire wafer surface is suitable for integrated circuit (IC) production. If disc geometry is out-of-spec after cutting, it may be possible to reprocess the wafer. Cutting is only the first [...]

Advantages of Measuring Semiconductor Thin Film Thickness with Capacitance

Semiconductor Thin Films: Measuring Thickness with Capacitance In the semiconductor industry, thin films are deposited onto silicon and other wafer materials one atomic layer at a time. The thickness of these extremely thin coatings is important because thin-film thickness affects the wafer’s electrical, optical, and mechanical properties. With semiconductors, either conductive metallic films or non-conductive metal oxide films are deposited. There are two main thin-film coating methods, chemical vapor deposition (CVD) and physical vapor deposition (PVD), both of which use a variety of processes. Because the coatings for semiconductor wafers are so thin, thickness measurement require a high degree [...]

Contact vs. Non-Contact Measurement and Linear Displacement Sensors

Contact vs. Non-Contact Measurement and Linear Displacement Sensors Linear displacement sensors are used to measure the distance between two points or two plane surfaces. They use various technologies, but there are two basic types: contact and non-contact. As their names suggest, contact sensors make physical contact with the object that is being measured and non-contact sensors do not. This is an obvious but important difference, but there is much more to consider. Non-contact measurement is faster than contact measurement, especially for applications with high sampling rates. Because contact-type devices must touch and then traverse the object, measurement is slower. [...]

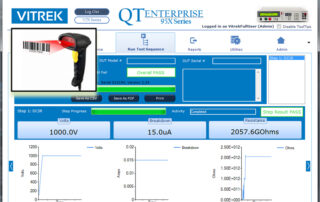

Press Release: Barcode Scanner Adds Functionality to Vitrek’s QT Enterprise Electrical Safety Testing Automation Software

Barcode Scanner Adds Functionality to Vitrek’s QT Enterprise Electrical Safety Testing Automation Software QT Enterprise software facilitates test sequence setup, report creation and data archiving; SQL database of test procedures and results accessible from multiple PCs; Barcode scanner input automatically loads and runs test sequences […]