Blogs

WAFER QA/QC AFTER SLICING AND POLISHING

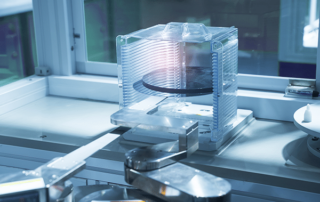

Industry Semiconductor Applications Wafer Qa/Qc After Slicing And Polishing Measurement Type Surface Description When wafers are sliced up with wire saws, they are measured to make sure they are within the specified thickness, with minimal bow, warp, and TTV. After initial measurement, they are sorted and sent for polishing. Since polishing removes material and smoothes out the rough surfaces they need to be measured again to ensure they meet thickness guidelines and quality standards. Solution: MTI Instruments manufactures multiple systems to perform thickness measurements. From semi automated Proforma 300SA to manual wafer [...]

GAAS SUBSTRATE THICKNESS MEASUREMENT

Industry Semiconductor Applications Gaas Substrate Thickness Measurement Measurement Type Thickness Description Measuring Thickness of Wafers with Different Chemistries Introduction: Silicon wafers are ordinarily highly conductive and easy to measure with standard capacitive displacement sensors (See MTI’s Proforma 300i). Measuring the thickness of GaAs wafers that have high bulk resistivity (>10k Ohm/cm) is a little more difficult because the wafers act as non-conductive insulators in a capacitive sensor’s measuring field. Fortunately, MTI has a solution to this problem. Solution: It’s possible to measure the thickness and TTV of high resistivity semiconducting wafers (like GaAs) using non-contact capacitive [...]

CAMERA SHIELD MEASUREMENT

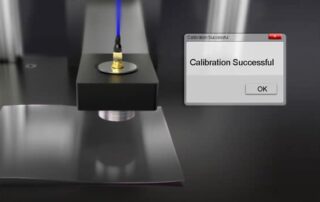

Equipment Setup Equipment Used DTS-25-04 laser head Rotary Stage PC with Digital Microtrak Basic Support software Setup Power is automatic mode. Filter is 100Hz Sample rate is 1000 samples sec The head was operated in diffuse mode (not specular/tilted) Validation of Setup The setup should be validated by performing a total runout scan on the rotary stage with no target present. The stage should be cleaned with Isopropyl alcohol and allowed to dry prior to the scan. This reduces any dust or dirt accumulation which will give a false reading of runout. A 360-degree runout of the rotary table, [...]

Testing for Connector Failure Due to Vibration or Shock

Testing for Connector Failure Due to Vibration or Shock Mobile Communications Equipment Needs Reliable Connectors That Will Not Disconnect with Shock or Vibration Introduction A large multinational company approached MTI to provide a sensor capable of measuring displacement that also wouldn’t load the target (connector). Shock and vibration testing would span 2-15G and the target connectors were very small. Application MTI’s 2100 optical displacement sensor system is ideal for this kind of application because very small probes can be used and they measure displacement via reflected light. Of course, reflected light does [...]

Camera Shield Measurement

Camera Shield Measurement Consumer Electronics Camera shield measurement Surface Equipment Setup Equipment Used DTS-25-04 laser head Rotary Stage PC with Digital Microtrak Basic Support software Setup: Power is automatic mode. Filter is 100Hz Sample rate is 1000 samples sec The head was operated in diffuse mode (not specular/tilted) Validation of Setup The setup should be validated by performing a total runout scan on the rotary stage with no target present. The stage should be cleaned with Isopropyl alcohol and allowed to dry prior to the scan. This reduces any dust [...]

GLASS THICKNESS

Industry Consumer Electronics Applications Glass Thickness Measurement Type Thickness Description Did you know that glass thickness can be measured with a capacitance probe? You will need some equipment: Digital Accumeasure D200 ASP-2500-CTA Dielectric probe (The capacitance probe has a sensing area of 11.25 mm) Range extension = 3X, 10Hz filter Introduction: An industrial glass fabricator needed a way to determine the thickness of glass, before cutting it to shape and coating it. The glass sample was marked with indices to find the measuring points. The sample center point -5- thickness was [...]

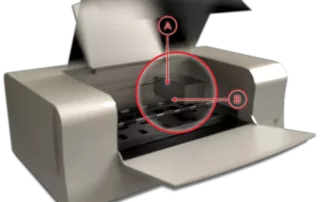

HEIGHT GAP OF INKJET PRINTERS

Industry Consumer Electronics Applications Height Gap Of Inkjet Printers Measurement Type Positioning Description Introduction: Inkjet printers require a certain distance between the inkjet print head and the paper. If the distance is set incorrectly, the printed images get blurry. Current state of the art printers have the print head nozzles built right into the bottom of the ink reservoir (B) as shown below. When the ink cartridge is installed in the printer, the inkjet nozzles (made out of silicon) essentially become a grounded target through the connections shown at [...]

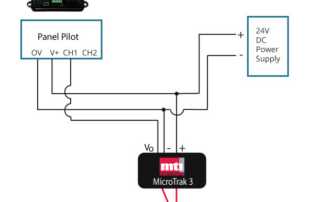

Adding a Digital Panel Meter to MTI Analog Output Products

Adding a Digital Panel Meter to MTI Analog Output Products Consumer Electronics Electronics Parts Profiling Thickness Description Some MTI Products with Analog outputs, Accumeasure 9000 and Microtrak 3 laser How To Use Digital Displays with Analog Outputs MTI Microtrak 3 Lasers and some of our Accumeasure amplifiers such as the Accumeasure 9000 only have analog outputs. If you wish to add a digital display, then the Lascar Panel pilot © makes a nice cost effective (~ $110) addition - Fig 1. These Digital panel meters have both [...]

MTI Video: Wafer Inspection & Metrology Startup (Proforma 300iSA)

https://youtu.be/mawagL6Yg3U

MTI Video: Wafer Inspection and Metrology Tutorial (Proforma 300i)

https://www.youtube.com/watch?v=nGkbpG2sz_k Learn More Download this brochure to learn more about the Proforma 300i wafer measurement system for semiconducting and semi-insulating wafers. This article in AZO Sensors also provides information.