Blogs

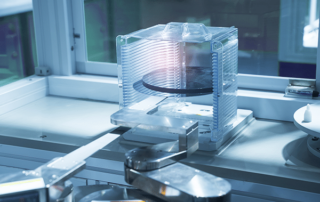

Capacitance Sensing for Non-Contact Thickness Measurements of Insulating Materials

Capacitance sensing can be used to make non-contact thickness measurements for most insulating materials. Capacitance sensors are known for their ability to precisely measure the thickness and position of conductive targets, but what’s less known is that these sensors can also measure the thickness of non-conductive materials. Examples include glass, sapphire, and plastics, as well as semi-insulating semiconductor materials such as GaAs and silicon nitride. Analog vs. Digital Technologies MTI Instruments, a global supplier of precision measurement technologies, takes the guesswork out of what used to be a complex measurement for non-conductive materials. MTI's Digital Accumeasure system features a [...]

White Paper: Cable & Connector Test System Facilitates Multi-Point High Voltage/Current Testing

White Paper: Cable & Connector Test System Facilitates Multi-Point High Voltage/Current Testing Introduction Hipot testing is critical in assuring compliance with a host of electrical safety standards and in confirming the assembled product is free from electrical or mechanical defects. Hipot testers are used to measure leakage current and insulation resistance between all components and connections, confirm solid ground connections and test ground bonds. All of these tests require the sequential application of precise and controlled high voltages or currents between pairs of elements then accurately measuring and recording the results. Products like the Vitrek 95x and V7x series [...]

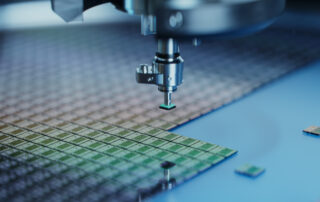

Trends in High Resolution Sensors for Semiconductor Metrology and Inspection

High resolution sensors are supporting improvements in semiconductor metrology and inspection at vital points in the production process. Because the fabrication of semiconductor wafers may require hundreds of steps and weeks of manufacturing time, early-stage defects that go undetected can have costly downstream consequences. Plus, because semiconductor processing always requires a high degree of precision, advances in fabrication methods seem to require ever-finer measurements in a never-ending quest. Today’s metrology instruments are incorporating high resolution sensors for automated wafer inspection. Resolution, the smallest measurement that a sensor can reliably indicate, may be given in dimensional units such as nanometers [...]

Vitrek featured in Appliance & HVAC Report

Click here to download a copy of this article featuring Vitrek Products! Click here to download a copy of this article featuring Vitrek Products!

Position, Displacement, and Vibration Measurement with Precision, High Resolution, and Flexibility

The MTI-2100 Fotonic™ sensor uses advanced fiber optics and electronics to precisely measure position, displacement, and vibration. This high-resolution, non-contact metrology system supports a wide range of interchangeable fiber-optic probes and works with almost any surface, including metallic, composite, plastic, glass, ceramic, or liquid. Made in the USA by MTI Instruments, the MTI-2100 Fotonic™ features a modular design and supports application-specific requirements in R&D, quality, and process control. With its dual channel capabilities, the MTI-2100 Fotonic™ sensor allows users to make simultaneous measurements, such as for structure dynamics and modal analysis. All probe modules have two distinct operating ranges [...]

How the Aviation Industry Solves Vibration and Balancing Challenges

The aviation industry spends significant amounts of time and money on problems caused by engine vibration. Imbalance, the most common cause of engine vibration, happens because of bird strikes and other impacts, but also because of natural wear and corrosion that redistribute mass. In turn, out-of-balance parts can result in cabin noise, metal fatigue, and cracked turbine, fan, or compressor components. In the most extreme cases, catastrophic engine failure may result MTI Instruments, a worldwide supplier of precision measurement solutions, makes equipment for monitoring vibration levels and balancing rotors. For maintenance, repair and overhaul (MRO) crews who want to [...]

White Paper: Precision Power Analyzers

White Paper All the tools needed to study and optimize virtually any power project in a single instrument Introduction The design of any power conversion system requires the measurement of a large range of electrical parameters that could be made using a lab bench full of instruments. The precision power analyzer pulls all of these measurements into a single instrument replacing meters, oscilloscopes, chart recorders, harmonic analyzers and other devices. This paper will provide a basic overview of the functions and capabilities of high-performance power analyzers. Examples of these functions and how to apply [...]

Five Common Mistakes with Semiconductor Wafer Measurement

Semiconductor wafer measurement requires a high degree of precision. The right metrology equipment and inspection processes are important, but so is procedural consistency and attention to detail. If you’re not getting the results you want, it’s time to look beyond the measurements. With bare semiconductor wafers, users need to avoid these five common mistakes. Mistake #1 | Turning the Device Off Most users turn on metrology devices only when it’s time to use them. As soon as semiconductor wafer measurement is complete, the devices are turned off. This reduces electricity consumption but also introduces thermal instability that can cause [...]

Press Release: QT Enterprise Electrical Safety Software Manages and Records Test Procedures

Vitrek’s QT Enterprise Electrical Safety Software Manages and Records Test Procedures Platform facilitates electrical safety test sequence setup, report creation and data archiving; SQL database of test procedures and results accessible from multiple PCs, bar coding feature enables accurate application of production test sequences. […]

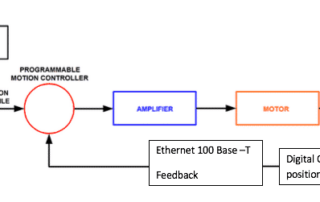

How to Implement a Complete Digital Closed Loop Control System

Co-authored by Don Welch, Director of Engineering and Business Development Cory Bufi, Software Engineer Isaac Abbott,Product Innovation Engineer – PBS Group Request Whitepaper Today’s electronic designs often call for reasonably fast and precise positioning of miniature components for process deposition elements such as ink jet nozzles, 3D printing elements etc. And as process control moves from mm positioning to micron to sub-micron positioning it becomes necessary to monitor and control positioning actuators such as piezo flexure stage and voice coil motors. Open loop control of the positioning stage may have been adequate in non-precision applications but piezo electric [...]