Blogs

Webinar Recap: Electrical Safety Testing for the Appliance & Consumer Product Industries

Vitrek is proud to hold educational webinars for our customers in various industries with information and products that are relevant to their applications. One such industry that relies on some of the technology that we offer is the appliance and consumer products industry, which requires extensive electrical safety testing in order to bring their products to market. All products that will be sold to consumers need to be tested by a Nationally Recognized Testing Laboratory (NRTL) in order to earn the proper safety certification. […]

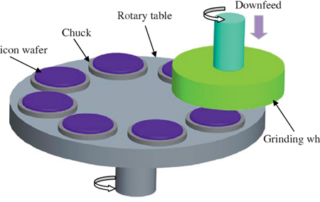

Wafer Backgrinding and Semiconductor Thickness Measurements

Wafer backgrinding is the first step in semiconductor packaging, the process of encasing one or more discrete semiconductor devices or integrated circuits (IC) for protection. Known also as wafer thinning or wafer lapping, backgrinding reduces wafer thickness to allow stacking and high-density IC packaging. Wafer thickness also determines package height, an important consideration as smartphones, laptops, and other electronic devices become thinner. With MEMS, wafer thinning also controls the proof mass for devices such as accelerometers or the diaphragm thickness for pressure sensors. Etching the surface of the wafer produces the IC but grinding the backside is what produces [...]

Silicon Carbide vs. Silicon in EV Power Electronics

Compare silicon carbide vs. silicon for electric vehicle (EV) power electronics and learn about SiC wafer measurement. As demand for electric vehicles (EVs) continues to grow, manufacturers are comparing two semiconductor technologies, silicon carbide and silicon, for power electronics applications. Silicon carbide (SiC) provides the high temperature resistance, low power consumption, rigidity, and support for smaller, thinner designs that EV power electronics need. Examples of SiC’s current applications include on-board DC/DC converters, off-board DC fast chargers, on-board battery chargers, EV powertrains, and automotive lighting for LEDs. According to Automotive World, SiC technology could also drive future EV innovations [...]

Film Sound Quality Control

Customer Case In performing quality control of the sound quality on film, the customer requires a fairly slow sampling and very high vertical resolution. Because the customer does not produce the actual film, there is a need to double-check the sound quality before it hits the theatres. Being sound, the highest frequency component is 20 KHz and they will probably oversample by a factor of 20. The customer would like to control the card via LabVIEW. GaGe Case Solution The CompuScope 1450 was suggested for its high resolution and ability to sample over a wide range of frequencies. Should [...]

White Paper: Electrical Safety & Compliance Testing for Appliance & Consumer Product Manufacturers

Introduction Electrical appliances, computers and peripherals, power tools and other devices found in the home and office environments must be tested to confirm adherence to a plethora of stringent certification standards. The vast array of consumer devices for the home and office — from blenders and ovens to computers and high-definition LED TVs — are becoming increasingly sophisticated. Refrigerators, once basic electrical appliances, now often include adjustable speed motor controls, digital displays and Bluetooth communications. While the complexity and functionality found in this class of devices varies extensively, there is one thing they all have in common when [...]

Press Release: Vitrek Announces New SE Series High Voltage Safety Enclosures

Vitrek Announces the SE Series of High Voltage Safety Enclosures The SE Series offers the utmost in operator safety for high voltage testing with solid aluminum frame construction, a durable acrylic cover and a magnetic interlock safety switch. […]

EV Batteries Need Thickness Gauging for Lower Costs and Higher Performance

EV batteries need to cost less and last longer. Until the e-mobility industry solves these challenges, electric vehicle (EV) adoption won’t match the hype that’s driven by Tesla, the established automakers, and a host of startups who are attracting investors. According to Axios, the expense of owning an electric vehicle will exceed that of owning a conventional one until EV batteries cost less than $100/KWh to produce. Unfortunately, the EV industry isn’t expected to hit that target for another ten years. Yet, there is some encouraging news. Less expensive and better performing EV batteries are just a few years [...]

High Resolution Semiconductor Wafer Measurements at Lower Costs

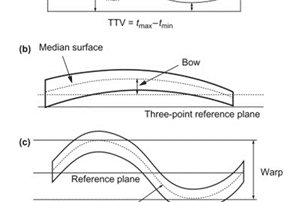

MTI's Proforma technology characterizes semiconductor wafers in terms of bow and warp, thickness, total thickness variation (TTV) and center thickness. Until recently, semiconductor wafer measurements at resolutions less than 100 µm were cost-prohibitive. Moreover, only expensive devices such as interferometers were capable of these measurements. Today, the semiconductor industry can use capacitance gauges instead of laser interferometers to achieve high resolution at fraction of the cost. Much like affordable CCD cameras transformed and expanded the market for video, cost-effective capacitance is disrupting the semiconductor wafer measurement market and creating new opportunities for quality testing and validation. The [...]

Measure Wafer Bow, Warp and TTV with Capacitance

The flatness of silicon wafers used to manufacture integrated circuits is controlled to tight tolerances to help ensure that the whole wafer is sufficiently flat for lithographic processing. To ensure your wafer manufacturing process is within tolerance, you need to measure the wafers being produced. Various measurement techniques exist to verify process tolerances and eliminate expensive scrap wafers. Non-contact capacitive sensing is a highly precise and cost-effective means to measure wafer flatness, bow, warp, and total thickness variation (TTV). MTI Instruments’ Proforma 300i and 300iSA systems use capacitance sensors to improve yields while reducing costs through better dimensional control of [...]

How to Measure Dielectric Separator Thickness in EV Batteries

The International Energy Agency predicts that as many as 125 million electric vehicles (EVs) will be on the road by 2030. At the heart of these electric cars, trucks, and buses is the lithium-ion (Li-ion) battery, a type of rechargeable battery with high energy density and low self-discharge. The plates in Li-ion batteries consist of lithium compounds that are applied to either a copper plate substrate (cathode) or an aluminum substrate (anode). In turn, these two plates are separated by a dielectric separator. All of the layers in an EV battery are extremely thin. In fact, the cathode and [...]