Blogs

Contact vs. Non-Contact Measurement and Linear Displacement Sensors

Contact vs. Non-Contact Measurement and Linear Displacement Sensors Linear displacement sensors are used to measure the distance between two points or two plane surfaces. They use various technologies, but there are two basic types: contact and non-contact. As their names suggest, contact sensors make physical contact with the object that is being measured and non-contact sensors do not. This is an obvious but important difference, but there is much more to consider. Non-contact measurement is faster than contact measurement, especially for applications with high sampling rates. Because contact-type devices must touch and then traverse the object, measurement is slower. [...]

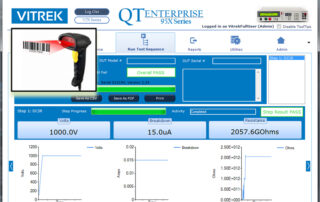

Press Release: Barcode Scanner Adds Functionality to Vitrek’s QT Enterprise Electrical Safety Testing Automation Software

Barcode Scanner Adds Functionality to Vitrek’s QT Enterprise Electrical Safety Testing Automation Software QT Enterprise software facilitates test sequence setup, report creation and data archiving; SQL database of test procedures and results accessible from multiple PCs; Barcode scanner input automatically loads and runs test sequences […]

Foam Density Measurement: Capacitance Sensors vs. Nuclear Gauges

This application note from MTI Instruments compares two technologies for measuring foam density: capacitance sensors and nuclear gauges. It examines the basic operating principles of each technology and explains why capacitance measurement is recommended for in-line measurement during foam manufacturing. Capacitance Sensors Capacitive probes are non-contact devices that use electric fields to measure foam density. In combination with a thickness value, a density measurement may be calculated. These probes consist of a capacitance sensor inside of a protective housing and are part of a larger measurement system that includes amplifiers, cables, and software. With parallel plate capacitance, the capacitance probe [...]

Using Capacitance Sensors for Non-Conductive Material Measurement

Non-Conductive Material Measurement with Capacitance Sensors Capacitance sensors are non-contact devices that can be used to obtain position, thickness, and dynamic measurements with a high degree of precision, accuracy, and resolution. Capacitive measurement is used with electrically-conductive materials such as metals but can also be used to measure non-conductive materials such as glass, sapphire, and many plastics. Even if a non-conductive material is relatively inexpensive (such as closed cell foam), manufacturers want to avoid errors that can result in significant waste across high volumes. Importantly, capacitance measurement is also used with semi-insulating materials such as gallium arsenide (GaAs) and [...]

Why Demand for SiC Wafers is Hot and Durable

Why Demand for SiC Wafers is Hot and Durable Pardon the pun, but SiC wafers are a hot item for high-temperature applications. Silicone carbide (SiC), a semiconductor containing both silicon and carbide, withstands temperatures up to 2700°C. Carborundum, as this durable ceramic is also known, finds additional applications in bulletproof vests, extrusion dies, sandpaper, and high-performance disc brakes. In electronics, SiC materials are used with light-emitting diodes (LEDs) and detectors. In the semiconductor industry, a market where interest is red-hot, SiC wafers are used in electronic devices that operate at high temperatures, high voltages, or both. Examples include electric [...]

Wafer Stress Analysis Using the 300iSA

Wafer Stress Analysis Using MTI Instruments Proforma 300iSAWafer processing involves several stages that may translate into mechanical alterations. Sometimes these alterations can cause deformities that render the wafer either unusable or that put it marginally close to not being usable. To determine this, stress analysis can be used.The Proforma 300iSA wafer characterization tool provides a software capability in which a wafer can be analyzed prior to processing and then after processing. The tool then evaluates how the wafer changed and hence, provides the resulting stress analysis.The software expects the customer to provide the material elasticity constants and to define them [...]

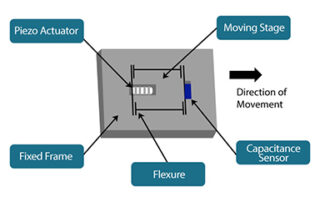

Capacitance Probes vs. Strain Gauges in Piezo Flexure Stages

Capacitance probes with pico-positioning sensors can be embedded in piezo flexure stages. With minor mounting modifications, these non-contact probes provide significantly greater accuracy than strain gauges. Piezo flexure stages are positioning devices with a high degree of resolution. These motion stages contain a piezoelectric actuator that converts an electrical signal into displacement based on the reverse piezoelectric effect, which is the ability of a piezo electric material to elongate when a voltage is applied. When a voltage (e.g., 0-150 VDC) is applied to the actuator, the stage moves in proportion to the applied voltage. Yet, the exact position remains [...]

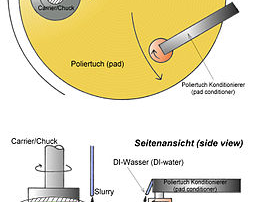

CMP and Capacitance-Based Semiconductor Wafer Measurement

Chemical mechanical polishing (CMP) uses chemical oxidation and mechanical abrasion to selectively remove material from semiconductor wafers in order to achieve very high levels of planarity. The planarity, or flatness, of these wafers is important for optical lithography, a microfabrication technique that produces integrated circuits (ICs) by transferring a geometric pattern from a photomask to a light-sensitive chemical photoresist. Also known as photolithography or UV lithography, optical lithography can produce a geometric pattern on a thin film or directly onto the substrate. Semiconductor Wafer Measurements: Flatness and Shape During optical lithography, variations in wafer flatness must be smaller than [...]

MEMS and Capacitance-Based Semiconductor Wafer Measurement

MEMS Technology and Capacitance-Based Wafer Measurement Micro-electrical-mechanical systems (MEMS) are tiny devices that house electrical and mechanical components on a single silicon chip or integrated circuit (IC). They integrate mechanical structures with electronics that are normally fabricated with complementary metal-oxide-semiconductor (CMOS) technologies. In addition to miniaturization, the benefits of MEMS include expanded functionalities at lower cost and with improved performance and reliability. With MEMS devices, critical physical dimensions range from smaller than one micron (µ) to larger than several millimeters (mm). In complex systems, multiple moving elements may be controlled by integrated electronics. Examples of the mechanical components in [...]

Measuring the Step Height Thickness of Non- Woven Conductive Films

Establishing and maintaining product quality throughout the production process is a common challenge of all manufacturers. How does an organization ensure the optimal output from their production lines, especially in real time? Key to this is strong non-destructive measurement practices that can take place at various points along the production process. The case study below is an example of how this was done at Saint-Gobain to measure the thickness and density of foam materials. They engaged with MTI's team of experts as their current direction was proving cost-prohibitive. Saint-Gobain's R&D organization, led by Dr. Mickael Boinet, found a solution [...]