Blogs

Case-In-Point: Step Height Measurement (Thickness) of Copper Foil or EV Battery Film on a Roller Rig

Step Height Measurement (Thickness) of Copper Foil or EV Battery Film on a Roller Rig Leverage MTI Instruments’ digital Accumeasure system to measure the thickness of the material used as anode and cathode plates in rechargeable Li-Ion battery cells Many roll-to-roll finishing processes typically use a calender, or series of hard pressure rollers, to deliver smooth, high-quality products of plastic, textile, or paper (Fig 1). Ensuring a consistent material thickness, however, depends on the ability to monitor, and maintain, a precise gap between rollers. This application note describes a quick and easy means for roller gap measurement. Introduction [...]

Case-In-Point: High-Accuracy Capacitive Thickness Measurement Optimizes Li-Ion EV Battery Plate Qualities

High-Accuracy Capacitive Thickness Measurement Optimizes Li-Ion EV Battery Plate Qualities EV Battery manufacturers need to measure EV battery plate thickness with a high degree of precision (repeatable <2um accuracy and resolution) to optimize manufacturing efficiencies while maintaining uniform cell capacity and minimizing waste. The MTI Accumeasure System provides an effective means of monitoring plate thickness achieving sub 2um accuracy with high repeatability Introduction The rapidly expanding demand for electric vehicles is driving advances in the production of rechargeable cells that comprise the first stage in the composition of EV battery packs. Individual Li-Ion cells are combined to [...]

MTI App Note: Step Height Measurement (Thickness) of Copper Foil or EV Battery Film on a Roller Rig

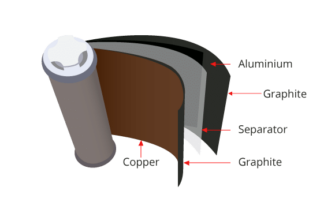

Step Height Measurement (Thickness) of Copper Foil or EV Battery Film on a Roller Rig Leverage MTI Instruments' digital Accumeasure system to measure the thickness of the material used as anode and cathode plates in rechargeable Li-Ion battery cells Introduction Figure 1. Simplified structure of a Li-Ion battery cell This white paper describes, in detail, how Non-Contact Measurement systems can be used to measure the thickness of the material used as anode and cathode plates in a rechargeable Li-Ion battery Cell. Figure 1 describes the elements comprising a Li-Ion battery cell. The cathode is comprised of [...]

High Precision Portable Signal Generators and Calibrators: Everything You Need to Know

High precision portable signal generators are portable electronic devices that generate highly precise signals for testing, system calibration, sensor simulation, troubleshooting, and monitoring. Unlike the benchtop signal generators that are used in laboratories, these hand-held portable devices are designed to be used in the field. The best high precision portable signal generators are also rugged and NIST traceable, meaning that their manufacturer calibrates them to standards from the National Institute of Standards and Technology (NIST). In terms of cost, high precision portable signal generators are more expensive than less precise, lower-end devices that can be held in the hand; [...]

MTI Application Note: How to Achieve <1um Accuracy When Measuring Roller Gap

How to Achieve <1um Accuracy When Measuring Roller Gap Roller Gap Measurement with MTI Digital Accumeasure Capacitive Probes Many roll-to-roll finishing processes typically use a calender, or series of hard pressure rollers, to deliver smooth, high-quality products of plastic, textile, or paper (Fig 1). Ensuring a consistent material thickness, however, depends on the ability to monitor, and maintain, a precise gap between rollers. This application note describes a quick and easy means for roller gap measurement. Problem How to measure the small gap between rollers to keep track of product thickness. Typically, it’s not possible to [...]

GaGe Application Note: Creating a Data Link Signal Integrity Test Platform

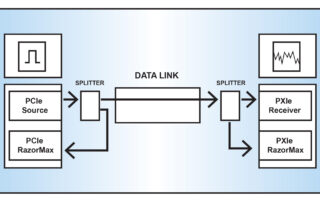

Creating a Data Link Signal Integrity Test Platform This application note describes how a manufacturer of data links utilizes GaGe Instruments’ PC-based high-speed data acquisition digitizers to perform production-level signal integrity testing. Data Link Device Testing The data link device under test (Figure 1) is characterized by comparing test signals that are input to the link with signals measured at the link output. Differences between these two test signals indicate a degradation by the link during transmission. The input and output test signals require sampling at 1 GS/s (GigaSample per second) with at least 14-bit vertical resolution. [...]

MTI Application Note: Testing for Connector Failure Due To Vibration or Shock

Testing for Connector Failure Due to Vibration or Shock Mobile Communications Equipment Needs Reliable Connectors That Will Not Disconnect with Shock or Vibration Introduction A large multinational company approached MTI to provide a sensor capable of measuring displacement that also wouldn’t load the target (connector). Shock and vibration testing would span 2-15G and the target connectors were very small. Application MTI’s 2100 optical displacement sensor system is ideal for this kind of application because very small probes can be used and they measure displacement via reflected light. [...]

MTI Whitepaper: Easy Roller Gap Measurement Ensures Calendering Success

Easy Roller Gap Measurement Ensures Calendering Success Many roll-to-roll finishing processes typically use a calender, or series of hard pressure rollers, to deliver smooth, high-quality products of plastic, textile, or paper (Fig 1). Ensuring a consistent material thickness, however, depends on the ability to monitor, and maintain, a precise gap between rollers. This application note describes a quick and easy means for roller gap measurement Problem Establishing a roller gap and checking for parallelism across roller width can be a slow and cumbersome procedure. Manual measurement requires multiple sized feeler gauges which can introduce errors. Misinterpreting [...]