Blogs

How Often Should Vibration Analysis Be Performed?

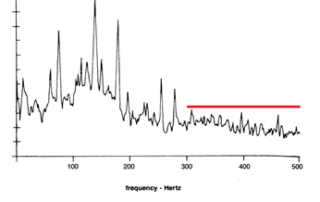

How Often Should Vibration Analysis Be Performed? Once a customer takes delivery of a PBS system and learns how to use it, the next logical question is: “How often should we use it?” At a minimum, your approved maintenance program (whether it’s a program developed by your operation, or the maintenance procedures outlined by the engine/airframe manufacturer) will tell you about the intervals at which to perform a vibration analysis. Usually, there is a procedure to specify how an engine vibration analysis and balance need be only completed when squawked by a pilot or after the completion of maintenance work [...]

Contact vs. Non-Contact Measurement and Linear Displacement Sensors

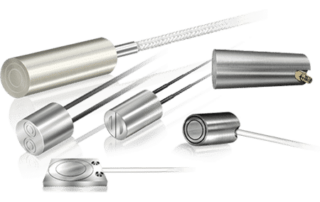

Contact vs. Non-Contact Measurement and Linear Displacement Sensors Linear displacement sensors are used to measure the distance between two points or two plane surfaces. They use various technologies, but there are two basic types: contact and non-contact. As their names suggest, contact sensors make physical contact with the object that is being measured and non-contact sensors do not. This is an obvious but important difference, but there is much more to consider. Non-contact measurement is faster than contact measurement, especially for applications with high sampling rates. Because contact-type devices must touch and then traverse the object, measurement is slower. [...]

Capacitance Sensors vs. Eddy Current Sensors Application Note

Capacitance Sensors vs. Eddy Current Sensors Application Note Capacitance sensors and Eddy current sensors are both used for non-contact measurements. Capacitive probes use electric fields to measure the distance from the sensor face to the surface of a target that is typically conductive and grounded. Eddy current probes use an alternating AC current to induce a magnetic field in a conductive target instead. In turn, the induced magnetic field produces a back magnetic field that is proportional to the gap between the probe face and the target. In a recent application note, MTI Instruments examines the differences between capacitance [...]

Press Release: Barcode Scanner Adds Functionality to Vitrek’s QT Enterprise Electrical Safety Testing Automation Software

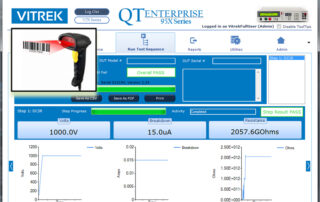

Barcode Scanner Adds Functionality to Vitrek’s QT Enterprise Electrical Safety Testing Automation Software QT Enterprise software facilitates test sequence setup, report creation and data archiving; SQL database of test procedures and results accessible from multiple PCs; Barcode scanner input automatically loads and runs test sequences […]

Ultrasonic Tissue Characterization

Ultrasonic Tissue Characterization Customer Case This customer's application is Ultrasonic Tissue Characterization. Their ultrasonic sensors transmit 16 signals. The customer's requirement is to capture 512 points on the 16 channels, average them together, and then store the data in a buffer, with the system running continuously. They would like to be able to update the average buffer and recapture data as fast as possible. They would then like to log the data to disk or process the data and display an image on the screen. Since the signals coming in from their ultrasonic sensors are very weak, the customer [...]

Digitizing Ultrasonic Signals

Digitizing Ultrasonic Signals Customer Case The customer has an ultrasonic signal that he wants to digitize with either 8 or 12-bit resolution. The sampling rate required for this application is a minimum of 16 MSPS (20 MSPS is acceptable). Finally, the data must be acquired for a full 10 seconds. The data is not coming in continuously: it is arriving in bursts one millisecond apart (PRF = 1 KHz). For each trigger the customer wants to capture approximately 200 us of data. Once this data is acquired, the customer wants it saved to the hard drive as a standard [...]

White Paper: Hipot Testing of Military/Aerospace Interconnect Components

Introduction Operational performance and safety are paramount concerns when determining the acceptability of a range of interconnection products in military and aerospace applications. Connectors and relays, wires, wire bundled into cables and harnesses, all must be tested against stringent standards. The number and range of these standards is mind-numbing — and this paper makes no attempt to catalog them all. Rather, notable and salient MIL standards and similar aerospace standards will be used to site the key role that high-performance electrical safety testers, ancillary equipment and software play in effecting reliable and cost-effective compliance testing of components as [...]

Digital Ultrasonic Array Data Capture

Digital Ultrasonic Array Data Capture Customer Case A customer possesses a commercial medical diagnostic ultrasonic system. The ultrasonic sensing head consists of an ultrasonic generator transducer and an 8' x 8' two-dimensional array of receiver transducers. The sensing head is pressed against the tissue under study and the generation transducer is periodically excited so that it emits a burst of ultrasonic energy. After each burst, the receiver array registers ultrasonic echoes reflected off tissue structures from each transducer element. In normal operation, digitized array data from each element is numerically processed and combined to construct a display image of [...]

Using Capacitance Sensors for Non-Conductive Material Measurement

Non-Conductive Material Measurement with Capacitance Sensors Capacitance sensors are non-contact devices that can be used to obtain position, thickness, and dynamic measurements with a high degree of precision, accuracy, and resolution. Capacitive measurement is used with electrically-conductive materials such as metals but can also be used to measure non-conductive materials such as glass, sapphire, and many plastics. Even if a non-conductive material is relatively inexpensive (such as closed cell foam), manufacturers want to avoid errors that can result in significant waste across high volumes. Importantly, capacitance measurement is also used with semi-insulating materials such as gallium arsenide (GaAs) and [...]

Semiconductor Wafer Lapping and Displacement Measurement

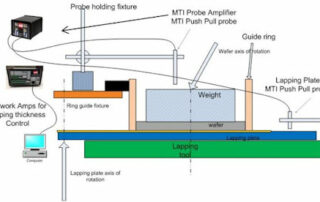

Semiconductor Wafer Lapping and Displacement Measurement Semiconductor Semiconductor Wafer Manufacturing Displacement Description Semiconductor Wafer Lapping and Displacement Measurement This application note explains how MTI’s Accumeasure technology was used with a lapping machine to measure displacement (wafer material removal) and determine the new semiconductor wafer thickness. Changes in electrical capacitance (displacement) were measured and then directly converted into a 24-bit digital reading to obtain precise digital thickness measurements. During lapping, a wafer of known start thickness is placed on a rotary lapping table. The backside of the wafer faces downward and [...]