Blogs

Tire Tread Measurement

Tire Tread Measurement Automotive Tire Tread Inspection Depth Description Tire manufacturers and Used Tire Reuse Centers want to satisfy their customers, and protect themselves from liabilities. Manufacturers are moving to 100% tire inspection for tread depth, defects and abnormality detection. Defects not only cause potential safety issues but they can also introduce unwanted vibration into the vehicle suspension system and cause excessive road noise. Belts can be overlapped, or not cover the complete tire surface, causing weak or bubbled areas and imbalances. The tread depth can be too shallow, leading [...]

Brake Rotors

Brake Rotors Automotive Brake Rotors Surface Description Introduction Under normal operating conditions brake rotors are subjected to extreme temperatures and forces, which can cause rotor distortion and potential failure. To make certain it can withstand these conditions; extensive laboratory testing is performed to optimize design for longevity, short stopping distance, and vibration free operation. Extensive on-vehicle testing is done under real life conditions to test prototype units and engineering designs. Test vehicles are driven for long periods of time while brake performance is monitored by a variety of sensors and data [...]

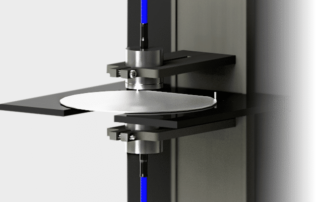

Wafer Characterization

Semiconductor Wafer Characterization Surface Description Thickness Measurement ASTM F657: The distance through a wafer between corresponding points on the front and back surface. Thickness is expressed in microns or mils (thousandths of an inch). Total Thickness Variation (TTV) ASTM F657: The difference between the maximum and minimum values of thickness encountered during a scan pattern or series of point measurements. TTV is expressed in microns or mils (thousandths of an inch). Figure above shows a wafer placed between two non-contact measurement probes. By monitoring changes between the upper probe [...]

Solenoid Door Latches

Solenoid Door Latches Aviation/ Aerospace Solenoid Door Latches Displacement Description A key supplier to the aerospace industry who manufactures many types of solenoid door latches was faced with the requirement to measure the motion of the lock plunger. Since the solenoid latch needs to complete the locking or unlocking cycle in as quickly as 13 milliseconds, it was critical to accurately track the fast motion of the plunger with a measurement system having a frequency response in excess of 100kHz. Because of the limited access to the interior of the [...]

Fiber Optic Probes Measure Stator Bar Vibration

Fiber Optic Probes Measure Stator Bar Vibration Power Generation, Industrial Stator Bar Vibration In A High Magnetic Field Amplitude Description [Application Note 11718] One of the primary concerns in large generator design is vibration. Excessive vibration can lead to premature breakdown of insulation and other materials, ultimately resulting in early failure of the generator itself. The Problem A leading manufacturer of power generating equipment required a sensing system able to measure stator bar vibration in a partial generator mockup. Specifically, the company's multi-day testing program demanded a sensing system that was [...]

Nuclear Heat Exchanger Vibration

Nuclear Heat Exchanger Vibration Power Generation Nuclear Heat Exchanger Vibration Amplitude Description Introduction: Power plants, particularly nuclear power plants, require heat exchangers to cool down the primary working fluid for the power plant. Excessive vibration can lead to cracking and premature failure of the heat exchanger. Problem: A major power plant company approached MTI looking for a sensor that could measure vibration of a heat exchanger assembly that was immersed under water. Additionally, the water could reach 250 F and up to 220 PSI; the probe had to be sealed [...]

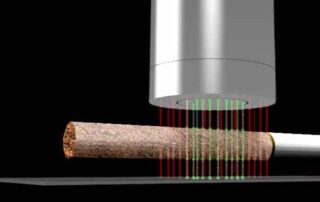

In-Situ Particle Detection

In-Situ Particle Detection Research & Development In-Situ Particle Detection Presence/Absence Description Introduction:  Foreign particles in food stuffs, plant produce, grains, etc. can lead to customer dissatisfaction when the items are packaged for sale. In some cases — it can be dangerous. Opportunity:  A major cigarette producer contacted MTI Instruments requesting a system to detect extraneous material, metal, plastic, filter fiber, and other contaminants. Background:  A cigarette’s dielectric footprint is controlled by the tobacco packing density, moisture content and the type of tobacco leaf. - packing density is controlled by the [...]

Piezoelectric Stack Motion

Piezoelectric Stack Motion Research & Development Piezoelectric Stack Motion Displacement Description Fotonic sensors are ideal for making dynamic measurement of very small oscillatory motions. Using the MTI-2100 with a spectrum analyzer, angstrom level measurements are possible. Would you like to know more? Okay let’s set up some basic equipment and get started. Piezoelectric crystals expand and contract when voltage is applied across the stack. By controlling the amplitude of the applied signal we control the magnitude of the displacement. The test setup A Spectrum Analyzer A Signal Generator to drive piezo device [...]

Thickness and TTV of Semiconducting Wafers

Thickness and TTV of Semiconducting Wafers Semiconductor Thickness And TTV Of Semiconducting Wafers Thickness Description Introduction:  Silicon wafers are ordinarily highly conductive and easy to measure with standard capacitive displacement sensors (See MTI’s Proforma 300i). Measuring the thickness of GaAs wafers that have high bulk resistivity (>10k Ohm/cm) is a little more difficult because the wafers act as non-conductive insulators in a capacitive sensors measuring field. Fortunately, MTI has a solution to this problem. Solution:  It’s possible to measure the thickness and TTV of high resistivity semiconducting wafers (like GaAs) [...]

Lithography Optics Position Focus

Lithography Optics Position Focus Semiconductor Lithography Optics Position Focus Positioning Description One specific area where capacitance systems excel is high resolution focusing of complex lens systems such as those found in atomic force microscopes, vision inspection machines and photolithography tools. In a multi-million dollar photolithography tool, high accuracy, nanometer resolution and maximum thermal stability are absolutely critical to maintain proper focus and obtain integrated circuit line widths as small as 45 nanometers. Additionally, most systems demand low power consumption and maximum heat dissipation to eliminate any adverse affects from temperature [...]