Blogs

Thickness Measurement of Dielectric Materials

Thickness Measurement of Dielectric Materials Manufacturing EV Battery Production Thickness, Distance --- Description --- Introduction Many applications, both in manufacturing and research, require precise material thickness measurements. This becomes especially difficult if the material is moving, is non conductive and/or translucent to clear. The specifics of your application may make accurate measurements difficult; many circumstances prohibit contact measurement, and make laser measurements difficult or impossible, for example with thin clear materials such as glass, sapphire, plastic . In cases such as these, capacitance measurement provides a highly accurate and cost-effective solution. [...]

Windshield Manufacturing

Industry Automotive Applications Oil Film Measurement Type Level Description In order to maintain proper profile and thickness within a glass furnace the extrusion plate spacing must be maintained at a predetermined gap. Unfortunately, due to process changes and temperature swings this gap can fluctuate significantly in short periods of time. This variation causes the glass thickness to change (check out our glass thickness measurement devices to accurately measure thickness), producing uneven temperature gradients and creating potentially weak glass panels. To control this critical parameter the manufacturing process requires automated active feedback [...]

Comparing Non-Contact Sensors: Capacitive vs. Eddy Current Sensors

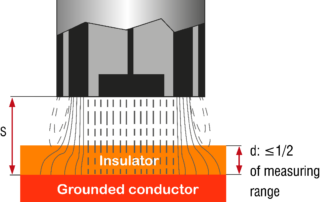

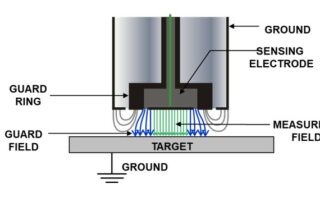

Comparing Non-Contact Sensors: Capacitive vs. Eddy Current Sensors Comparing Non-Contact Sensors: Capacitive vs. Eddy Current Sensors Manufacturing EV Battery Production Thickness, Distance This application note from MTI Instruments compares two types of non-contact sensors: capacitive and Eddy current. It describes their basic operating principles, includes a quick comparison table, and offers recommendations for use. Capacitance Sensors: Basic Operating Principles Capacitive probes use electric fields to measure the distance from the sensor face to the target surface. A guard ring around the capacitive sensor in the probe steers the direction of [...]

Vibration and Balancing Systems: The Spectrum Plot

The Spectrum Plot: Types of Aircraft Vibration One of the least understood features of the PBS series of vibration analyzers is the spectrum function. The spectrum functionality is a more difficult function to understand, but once mastered, technicians can quickly develop an extremely in-depth understanding on what is going on in an engine during a test. Figure 1, below, shows a basic spectrum from the PBS system. On the x-axis is frequency, measured in Hz (per second). On the y-axis is amplitude, measured in units of velocity, inches per second pk, or IPS pk. Figure 1: Basic Spectrum [...]

GRINDING PROCESS

A cylindrical grinding process finishes most wheel spindle surfaces. It is essential that this grinding process leave a surface finish that is smooth and free of defects with minimal runout. No grinder produces a perfect surface. Grinder wheel runout, improperly dressed wheels and fixture vibrations can cause chatter on the spindle surface finish. Chatter is a series of microscopic, repetitive imperfections, or waves, in the surface of the material being machined. The required production environment sensor must have small spatial resolution, high frequency response and large standoff distance for easy loading and unloading of parts. Additionally, the measurement accuracy had to [...]

Ideal Charge Amplifier for Piezo Electric Transducers

Ideal Charge Amplifier for Piezo Electric Transducers Aviation (Turbine Engines), Automotive Research and Development, Industrial Manufacturing Vibration Monitoring: Turbine Engines; Vehicle Testing Pressure Monitoring: Combustion Engines; Pumps, Turbines Amplitude Measurements:  Acceleration, Vibration, Pressure Description Ideal Charge Amplifier for Piezo Electric Transducers Piezoelectric-type transducers such as accelerometers used for turbine vibration measurement and pressure transducers used for combustion dynamics monitoring (CDM) produce a high-impedance charge output that must be conditioned and amplified before transmission across system cabling and into measurement instrumentation. Challenge A piezoelectric transducer is a sensor that produces a [...]

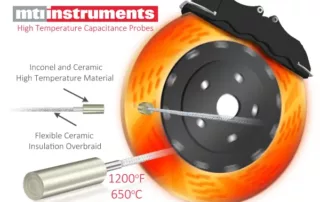

BRAKE ROTORS THICKNESS VARIATION

Industry Automotive Applications Brake Rotors Thickness Variation Measurement Type Surface Description Driving cross country or cross town, we give little thought to the operation or complexity of our vehicle braking systems. They only cross our mind when we absolutely need them; we never stop to think about the extensive design and testing that makes them such a lifesaver. Take the brake rotor for example. Under normal operating conditions it’s subjected to extreme temperatures and forces, which can cause rotor distortion and potential failure. To make certain it can withstand [...]

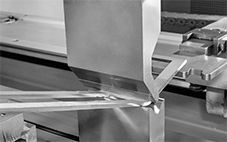

Angle Measurement And Monitoring

Angle Measurement And Monitoring Industrial Angle Measurement And Monitoring Robot Guide Description Introduction So what do sheet metal, speakers, and wine bottles all have in common? They represent the many angles and profiles that can be measured with laser sensor head. Angles: Numerous applications call for measuring angles such as sheet metal Press Brake applications. As the Press Brake bends the sheet metal, the controller reads the actual bend angle from the sensor head and can control under/over bending to reduce product waste and time. Sensor measurements can easily be interfaced [...]

OIL FILM THICKNESS MEASUREMENT

Industry Automotive Applications Oil Film Measurement Type Level Description A top marine engine manufacturer commissioned MTI Instruments to design and manufacture a non-contact sensor to measure the microscopic oil film layer between the engine cylinder wall and the piston ring. Engine testing is normally performed through a range of low RPM’s to high RPM’s (400- 6000) with piston linear speeds approaching 500 inches/second and at various torques. A measuring system with high frequency response and small sensor size was essential to keep engine machining to a minimum while not altering [...]

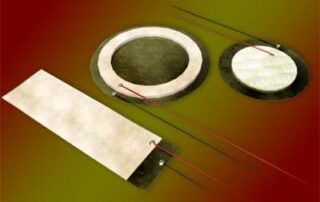

Piezoelectric Device Amplitude

Piezoelectric Device Amplitude Research & Development Piezoceramic, 1-3 Pzt / Polymer Composite And Pvdf Film Amplitude Description Measuring Piezoelectric device amplitude including piezoceramic, 1-3 PZT/polymer composite and PVDF film A “PZT ” is a piezoelectric device which generates motion when a voltage is applied across the crystal. The motion can be anywhere from DC to ultrasonic and the motion is typically very small. PZT devices are used to generate sound and to convert voltage to motion. MTI's MTI-2100 controller in conjunction with a High resolution fiber optic probe such as [...]