Blogs

Transducer Selection for High Resolution Applications

High resolution applications do not always require an interferometer. If you want to make accurate measurements in the micron to picometer range, then an MTI Digital Accumeasure D100 HD or D200 system may be what you need. Laser interferometers can sell for more than $15,000 and be difficult to setup. For example, you may have to buy additional optics to guarantee a good return signal since the laser beam must reflect off a mirror surface or precision retro reflector in order for the beam to re-enter the interferometer’s optics at less than a degree of reflection angle. The downsides [...]

Vibration Test Equipment Instrument Grade Chassis

Vibration Test Equipment Instrument Grade Chassis Customer Case The customer is in the business of building Vibration Test equipment for semiconductor, automotive and aerospace industries. Their product is currently housed in Industrial Grade PCs which they integrate themselves. They currently purchase the chassis from an off-shore company. Their major problem is product differentiation: their product looks like "just another PC" and, therefore, cannot command a better price point. They also presently have to ship a separate monitor, as one is not integrated in the chassis. They want to upgrade the chassis to one of better quality, with a more [...]

Non-Destructive Testing (NDT)

Non-Destructive Testing (NDT) Customer Case This customer manufactures non-destructive test equipment which allows customers such as steel mills to test the quality of their end-products. Presently, the ultrasound frequencies being used are centered at either 5 MHz, 10 MHz or 15 MHz. The worst case analog bandwidth requirement in this case is 35 MHz. In order to set up their equipment properly, the customer presently views the return signal (including the flaw) on an analog oscilloscope with a sweep time of either 50 us or 100 us (providing approximately 5 to 10 inches of depth in a metal). The [...]

High Resolution Semiconductor Wafer Measurements at Lower Costs

MTI's Proforma technology characterizes semiconductor wafers in terms of bow and warp, thickness, total thickness variation (TTV) and center thickness. Until recently, semiconductor wafer measurements at resolutions less than 100 µm were cost-prohibitive. Moreover, only expensive devices such as interferometers were capable of these measurements. Today, the semiconductor industry can use capacitance gauges instead of laser interferometers to achieve high resolution at fraction of the cost. Much like affordable CCD cameras transformed and expanded the market for video, cost-effective capacitance is disrupting the semiconductor wafer measurement market and creating new opportunities for quality testing and validation. The [...]

Acoustic Micro-Imaging

Acoustic Micro-Imaging Customer Case The customer is a leader in the field of acoustic micro-imaging. They use pulse ultrasound to image non-human materials. The ultrasound frequency used is between 100 and 200 MHz, as the materials they study can handle these frequencies (one cannot normally use such high frequencies with human tissue). The customer's PRF (Pulse Repeat Frequency) is approximately 4 KHz, with a PRI (Pulse Repeat Interval) of 250 ms. They need to capture approximately 2 ms (1,000 points) of data for each pulse. The customer wants scope emulation software to allow verification of board operation without having [...]

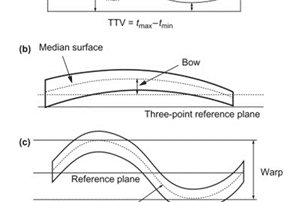

Measure Wafer Bow, Warp and TTV with Capacitance

The flatness of silicon wafers used to manufacture integrated circuits is controlled to tight tolerances to help ensure that the whole wafer is sufficiently flat for lithographic processing. To ensure your wafer manufacturing process is within tolerance, you need to measure the wafers being produced. Various measurement techniques exist to verify process tolerances and eliminate expensive scrap wafers. Non-contact capacitive sensing is a highly precise and cost-effective means to measure wafer flatness, bow, warp, and total thickness variation (TTV). MTI Instruments’ Proforma 300i and 300iSA systems use capacitance sensors to improve yields while reducing costs through better dimensional control of [...]

Non-Destructive Testing (NDT) Scanning Inspection

Non-Destructive Testing (NDT) Scanning Inspection Customer Case The customer is testing interior of pipes with time-resolved fluorescence, a Photo Multiplier Tube (PMT), a transducer with 8 MHz BandWidth and an integration chamber. They are searching for rare events and the scan width is approximately 3.5 inches. Multiple Record: 350 scans x 3 Kpts. GaGe Case Solution We recommended 5X-10X over sampling - therefore CompuScope 14100, CompuScope 12100, or even the 8-bit CS8500 may be sufficient. For a CS8500 Single Record example, say, at the single-channel sampling-rate of 50 MS/s, a 3000 point (i.e. 3 KS) acquisition would take about [...]

Non-Destructive Testing (NDT) of Concrete Structures

Non-Destructive Testing (NDT) of Concrete Structures Customer Case Our customer needs to perform Non Destructive Testing (NDT) to test concrete. The testing method involves using a special hammer mounted with a geophone, which serves as a transducer. They strike the concrete structure with the hammer and record the results for analysis. A definitive echo in the signal will be appear should there be a crack or a weak point in the concrete. GaGe Case Solution The customer was looking for a low-cost board that would be able to sample at 20 MHz or more, so we recommended the CompuScope [...]

Non-Destructive Testing (NDT) for Steel Manufacturing

Non-Destructive Testing (NDT) for Steel Manufacturing Customer Case The customer is a custom-built contractor of Non-Destructive Test (NDT) instruments for steel manufacturing. NDT uses ultrasonic pulses to scan through thick sheets of metals for possible causes of early wear, such as cracks or impurities. The stimulus is a stream of ultrasonic pulses. The response is their reflection from various depths. The center frequencies used by this customer are in the range of 250 KHz to 2.25 MHz and pulses are about 10 microseconds. The pulse repeat frequency (PRF) is less than 1 KHz. The thickness of steel sheets is [...]

How to Measure Dielectric Separator Thickness in EV Batteries

The International Energy Agency predicts that as many as 125 million electric vehicles (EVs) will be on the road by 2030. At the heart of these electric cars, trucks, and buses is the lithium-ion (Li-ion) battery, a type of rechargeable battery with high energy density and low self-discharge. The plates in Li-ion batteries consist of lithium compounds that are applied to either a copper plate substrate (cathode) or an aluminum substrate (anode). In turn, these two plates are separated by a dielectric separator. All of the layers in an EV battery are extremely thin. In fact, the cathode and [...]