Blogs

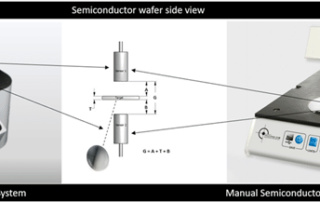

Why Disc Geometry Matters In Wafer Production

This is the first of three articles in Semiconductor Wafer Measurement for Increased Profitability. The second article examines the cost of failing to inspect semiconductor wafers. The third article describes the benefits of using semi-automated, fully-automated, and manual systems for wafer metrology and inspection. Semiconductor wafers are cut from cylindrical silicon crystals, or ingots. The flatness of these disc-shaped wafers is controlled to tight tolerances to ensure that the entire wafer surface is suitable for integrated circuit (IC) production. If disc geometry is out-of-spec after cutting, it may be possible to reprocess the wafer. Cutting is only the first [...]

High-Speed Digitizer Advantages

GaGe is a worldwide industry leader in high speed data acquisition solutions featuring a portfolio of the highest performance digitizers, PC oscilloscope and spectrum analayzer software, powerful SDKs for custom application development, and turnkey integrated PC-based measurement systems. Some of the primary advantages of selecting GaGe digitizers for your application include: Digitizer Effective Number of Bits (ENOB) Performance GaGe high-performance digitizers are renowned for sustaining the maximum effective number of bits (ENOB) over a wide signal frequency range with quality signal conditioning and signal fidelity features. Most engineers and scientists focus on sample rate and resolution when selecting high speed [...]

How Capacitive Measurement Can Help Reduce Packaging Waste

Product packaging is often made of lightweight polymeric foams or plastic sheets and films. These materials are relatively inexpensive, but manufacturers still want to minimize waste and maximize yields. Across high volumes of low-cost materials, even a small per-unit savings can become significant, especially as the price of petroleum – a key ingredient in many polymers – continues to rise. For companies with environmental sustainability efforts, there are other important considerations as well. The excessive use of packaging materials can contribute to environmental pollution, especially with polymers that are slow to degrade. Yet, materials such as plastic sheets and [...]

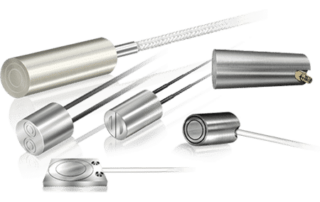

Non-Contact Displacement Sensors for Detection and Measurement

Non-contact sensors detect or measure a physical property without making direct contact with the target, the object that is being monitored or measured. They are used to measure physical properties such as thickness, proximity, displacement, or distance. To obtain readings, non-contact displacement sensors emit a form of energy and may use capacitance, fiber optic, or laser triangulation technologies. By contrast, contact sensors must touch the target and often rely upon mechanical movement. Non-Contact Sensors vs. Contact Sensors Non-contact sensors are faster, especially for applications with high sampling rates, and won’t dampen the motion of a target. They can also [...]

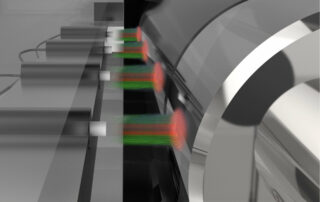

Advantages of Measuring Semiconductor Thin Film Thickness with Capacitance

Semiconductor Thin Films: Measuring Thickness with Capacitance In the semiconductor industry, thin films are deposited onto silicon and other wafer materials one atomic layer at a time. The thickness of these extremely thin coatings is important because thin-film thickness affects the wafer’s electrical, optical, and mechanical properties. With semiconductors, either conductive metallic films or non-conductive metal oxide films are deposited. There are two main thin-film coating methods, chemical vapor deposition (CVD) and physical vapor deposition (PVD), both of which use a variety of processes. Because the coatings for semiconductor wafers are so thin, thickness measurement require a high degree [...]

CEMENT BOARD QUALITY CONTROL

Cement backer board is used as underlayment for tile floors, walls and counter tops. It is also used as exterior sheathing and in exterior stucco systems. Cement backer board has proven to be more durable than virtually any other underlayment if quality control and thickness is maintained. The Problem: A major cement board manufacturer was faced with the challenge to improve a board production line throughput and decrease the amount of waste in the process. Too thin of cement board material weakens it structurally, while board that is too thick wastes material and resources, as well as drives up production costs. [...]

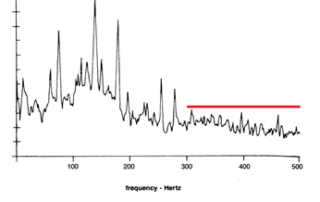

How Often Should Vibration Analysis Be Performed?

How Often Should Vibration Analysis Be Performed? Once a customer takes delivery of a PBS system and learns how to use it, the next logical question is: “How often should we use it?” At a minimum, your approved maintenance program (whether it’s a program developed by your operation, or the maintenance procedures outlined by the engine/airframe manufacturer) will tell you about the intervals at which to perform a vibration analysis. Usually, there is a procedure to specify how an engine vibration analysis and balance need be only completed when squawked by a pilot or after the completion of maintenance work [...]

Contact vs. Non-Contact Measurement and Linear Displacement Sensors

Contact vs. Non-Contact Measurement and Linear Displacement Sensors Linear displacement sensors are used to measure the distance between two points or two plane surfaces. They use various technologies, but there are two basic types: contact and non-contact. As their names suggest, contact sensors make physical contact with the object that is being measured and non-contact sensors do not. This is an obvious but important difference, but there is much more to consider. Non-contact measurement is faster than contact measurement, especially for applications with high sampling rates. Because contact-type devices must touch and then traverse the object, measurement is slower. [...]

Capacitance Sensors vs. Eddy Current Sensors Application Note

Capacitance Sensors vs. Eddy Current Sensors Application Note Capacitance sensors and Eddy current sensors are both used for non-contact measurements. Capacitive probes use electric fields to measure the distance from the sensor face to the surface of a target that is typically conductive and grounded. Eddy current probes use an alternating AC current to induce a magnetic field in a conductive target instead. In turn, the induced magnetic field produces a back magnetic field that is proportional to the gap between the probe face and the target. In a recent application note, MTI Instruments examines the differences between capacitance [...]

Ultrasonic Tissue Characterization

Ultrasonic Tissue Characterization Customer Case This customer's application is Ultrasonic Tissue Characterization. Their ultrasonic sensors transmit 16 signals. The customer's requirement is to capture 512 points on the 16 channels, average them together, and then store the data in a buffer, with the system running continuously. They would like to be able to update the average buffer and recapture data as fast as possible. They would then like to log the data to disk or process the data and display an image on the screen. Since the signals coming in from their ultrasonic sensors are very weak, the customer [...]