Blogs

MTI Application Note: How to Achieve <1um Accuracy When Measuring Roller Gap

How to Achieve <1um Accuracy When Measuring Roller Gap Roller Gap Measurement with MTI Digital Accumeasure Capacitive Probes Many roll-to-roll finishing processes typically use a calender, or series of hard pressure rollers, to deliver smooth, high-quality products of plastic, textile, or paper (Fig 1). Ensuring a consistent material thickness, however, depends on the ability to monitor, and maintain, a precise gap between rollers. This application note describes a quick and easy means for roller gap measurement. Problem How to measure the small gap between rollers to keep track of product thickness. Typically, it’s not possible to [...]

GaGe Application Note: Creating a Data Link Signal Integrity Test Platform

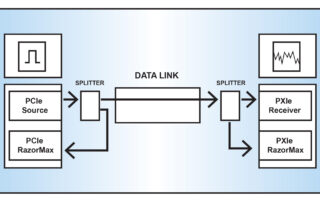

Creating a Data Link Signal Integrity Test Platform This application note describes how a manufacturer of data links utilizes GaGe Instruments’ PC-based high-speed data acquisition digitizers to perform production-level signal integrity testing. Data Link Device Testing The data link device under test (Figure 1) is characterized by comparing test signals that are input to the link with signals measured at the link output. Differences between these two test signals indicate a degradation by the link during transmission. The input and output test signals require sampling at 1 GS/s (GigaSample per second) with at least 14-bit vertical resolution. [...]

MTI Application Note: Security of Flight Doors Improved Through Use of MTI-2100 Fotonic Sensor

Security of Flight Doors Improved Through Use of MTI-2100 Fotonic Sensor Increased Safety & Reliability for Aircraft Cockpit Doors NTSB safety records point to numerous incidents involving cockpit door locking/unlocking mechanisms, either accidentally opening/closing or not operating fact enough upon command. Learn how one key industry supplier leveraged Fotonic Sensors to increase reliability and safety for their door locking mechanisms. Introduction Figure 1. Example of a typical cockpit door strike NTSB safety records point to numerous incidents involving cockpit door locking/unlocking mechanisms, either accidentally opening/closing or not operating fast enough upon command. In the assembly [...]

MTI Case-In-Point: Gap Monitor Keeps Wind Turbines Running

Gap Monitor Keeps Wind Turbines Running System helps operators minimize downtime and protect against catastrophic failure Introduction Wind turbine production has been steadily increasing to meet growing demand for renewable energy. As power outputs and the number of installations climb, maintenance becomes ever more critical. Operators want to minimize downtime and protect against catastrophic failure. The ability to predict when maintenance will be required can go a long way to ensure these goals are met. Challenge A leading manufacturer of wind turbine power generators approached MTI for critical gap monitoring sensors. Specifically, the company wished to [...]

MTI Application Note: Testing for Connector Failure Due To Vibration or Shock

Testing for Connector Failure Due to Vibration or Shock Mobile Communications Equipment Needs Reliable Connectors That Will Not Disconnect with Shock or Vibration Introduction A large multinational company approached MTI to provide a sensor capable of measuring displacement that also wouldn’t load the target (connector). Shock and vibration testing would span 2-15G and the target connectors were very small. Application MTI’s 2100 optical displacement sensor system is ideal for this kind of application because very small probes can be used and they measure displacement via reflected light. [...]

Application Note: How to Ensure Your LED Lighting Products Meet Industry Standards

Testing for performance, energy effeciency, consumption verification, quality and safety compliance during product development. Introduction Manufacturers and users of LED lighting products need to ensure that their products meet the qualifications and requirements of a multitude of reliability and efficiency standards. In addition to voluntary initiatives and programs like EnergyStar, mandatory standards and specifications for the lighting industry must be kept in mind during project development, including the latest IES LM-79-19 and the ANSI C82.16 documents. This application note provides an overview of relevant lighting standards and specifications for LED lighting products. [...]

GaGe Application Note: Creating a Data Link Signal Integrity Test Platform

Download a PDF Copy of this App Note Data Link Device Testing The data link device under test (Figure 1) is characterized by comparing test signals that are input to the link with signals measured at the link output. Differences between these two test signals indicate a degradation by the link during transmission. Figure 1. Two test platforms (PCIe and PXIe, respectively) transmit and receive the data link test signals. GaGe RazorMax high-speed data acquisition cards record the data for signal integrity comparison. The input and output test signals require sampling at 1 GS/s (GigaSample per second) [...]

A Comprehensive Guide to Non-Contact Sensors and Their Applications

A Comprehensive Guide to Non-Contact Sensors and Their ApplicationsSensors, both contact and non-contact, are crucial devices that allow the monitoring, detection, and reaction to conditions in an environment or within a process or piece of equipment. While myriad types of sensors exist and are designed to monitor varying conditions, all of them can be characterized as being one of two types — contact sensors and non-contact sensors. We’ll focus on the latter, diving into different technologies, types, and applications of non-contact sensor technology; but first, let’s explore what differentiates contact and non-contact sensors.Contact vs. Non-Contact Sensors: What’s the Difference?Measuring, monitoring, [...]

Vitrek’s Automated Testing System Simplifies and Speeds Automotive Cable/Harness Testing

Vitrek's Automated Testing System Simplifies and Speeds Automotive Cable/Harness Testing Testing system combines a hipot tester with Vitrek’s 964i switching system and QT Enterprise software; the automated approach enables manufacturers to configure tests easily and access historical data Introduction With 20 or more harnesses, many interfacing with digital control devices, today's vehicles have increasingly complex electronic systems. Precise and accurate continuity and cable testing must be performed on every connection during the assembly process to assure safety and reliability in the application. This article presents a highly functional, automated approach to automotive/cable harness testing. It describes [...]

The Benefits of Manual, Semi-Automated, and Fully-Automated Systems for Semiconductor Wafer Inspection and Metrology

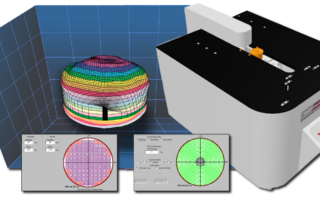

This is the third of three articles in Semiconductor Wafer Measurement for Increased Profitability. The first article in this series explains why disc geometry matters. The second article examines the cost of failing to inspect semiconductor wafers. Fully automated systems that can load, scan, and unload wafers are fast, convenient, and efficient at high volumes. They’re useful for checking every wafer in every batch, but these systems are expensive. Semi-automated and manual systems cost significantly less and are generally used for lower volumes; however, they’re also easy-to-use and can make fast, accurate measurements that support production flow. Semi-automated and [...]