Blogs

Generator Pole Gap Analysis

Power Generation Generator Pole Gap Analysis Tolerances Description

Grinding Process

Grinding Process Automotive Grinding Process Surface Description A cylindrical grinding process finishes most wheel spindle surfaces. It is essential that this grinding process leave a surface finish that is smooth and free of defects with minimal runout. No grinder produces a perfect surface. Grinder wheel runout, improperly dressed wheels and fixture vibrations can cause chatter on the spindle surface finish. Chatter is a series of microscopic, repetitive imperfections, or waves, in the surface of the material being machined. The required production environment sensor must have small spatial resolution, high frequency [...]

Spindle Run Out

Spindle Run Out Automotive Spindle Run Out Distance Description Rotating targets frequently have an intermittent, uncertain or nonexistent ground path. This introduces unwanted noise, instability, drift and reduces accuracy of the measurement. MTI Instruments offers a unique "Push-Pull" capacitance measurement system that does not require a grounded target. It utilizes two probes, built into one body, that work together to complete the ground path. One probe pushes current into the brake rotor while the adjacent probe pulls the current out. The result is a "clean", consistent electrical sensing path. As [...]

Thread Checking

Automotive Thread Checking Presence/Absence Description Manual thread inspection is slow, not always reliable and tedious for the inspector. Manufacturers have struggled to come up with ways to reliably automate the process at a reasonable cost. Automated systems are available that use “screw sensors” can quickly wear or be cross threaded, requiring operator attention and a tooling change. A worn screw can provide false rejections leading to the unnecessary scrapping of parts. Capacitance solutions are cost effective alternative which are becoming increasingly popular due to their high reliability and fast [...]

Piezo Stage Positioning

Piezo Stage Positioning Consumer Electronics Piezo Stage Positioning Description Positioning stages using piezoelectric stack actuators (PEA) have very high resolution. However, it is difficult to achieve precise dynamic motion tracking using traditional linear controllers such as PID due to the inherent hysteresis nonlinearity of piezoelectric materials and the phase lag associated with such controllers. Capacitance Sensors are ideal for measuring the actual piezo stage position and correcting for the inherent nonlinearity through closed loop feedback. They have the stability, bandwidth and high resolution needed to do the job. Several of [...]

Glass Thickness

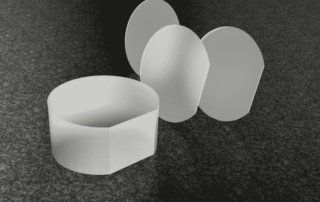

Glass Thickness Consumer Electronics Glass Thickness Thickness Description Did you know that glass thickness can be measured with a capacitance probe? You will need some equipment: Digital Accumeasure D200 ASP-2500-CTA Dielectric probe (The capacitance probe has a sensing area of 11.25 mm) Range extension = 3X, 10Hz filter Introduction:  An industrial glass fabricator needed a way to determine the thickness of glass, before cutting it to shape and coating it. The glass sample was marked with indices to find the measuring points. The sample center point -5- thickness was checked with [...]

Electronics Parts Profiling

Electronics Parts Profiling Consumer Electronics Electronics Parts Profiling Thickness Description MTI's 2D laser sensors can be used to scan 3D profiles of items such as printed circuit boards to verify all the parts are installed, making sure parts don’t exceed certain heights or that the part is present. You can even plot or examine the image intensity profile of the 2D sensor which yields a monochromatic image of the target and this can be used with OCR software or barcode software to recognize product codes, check if labels are present [...]

Height Gap Of Inkjet Printers

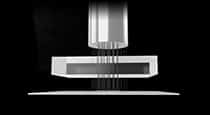

Height Gap Of Inkjet Printers Consumer Electronics Height Gap Of Inkjet Printers Positioning Description Introduction:  Inkjet printers require a certain distance between the inkjet print head and the paper. If the distance is set incorrectly, the printed images get blurry. Current state of the art printers have the print head nozzles built right into the bottom of the ink reservoir (B) as shown below. When the ink cartridge is installed in the printer, the inkjet nozzles (made out of silicon) essentially become a grounded target through the connections shown at [...]

Wafer Measurement – Ungrounded

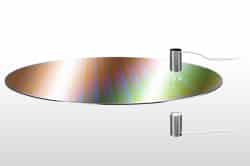

Wafer Measurement - Ungrounded Semiconductor Wafer Measurement - Ungrounded Metrology Description MTI Instruments Inc. has developed a thickness measurement device that eliminates the effect of varying target conductivity. Called the Push-Pull probe, it’s a unique version of the AccumeasureTM amplifier series. This special design provides accurate surface information for wafer bow and warp. Bow is the deviation of the center point of the median surface of a free, un-clamped wafer from the median surface to the reference plane. Where, the reference plane is defined by three corners of equilateral triangle. This [...]

Wafer Thickness, Bow, Warp And TTV

Semiconductor Wafer Thickness, Bow, Warp And Ttv Surface Description Thickness Measurement ASTM F657: The distance through a wafer between corresponding points on the front and back surface. Thickness is expressed in microns or mils (thousandths of an inch). Total Thickness Variation (TTV) ASTM F657: The difference between the maximum and minimum values of thickness encountered during a scan pattern or series of point measurements. TTV is expressed in microns or mils (thousandths of an inch). Figure above shows a wafer placed between two non-contact measurement probes. By monitoring changes [...]