Blogs

MONITOR ROLLER GAPS AND PARALLELISM

Easy Roller Gap Measurement Ensures Calendering Success Many roll-to-roll finishing processes typically use a calender, or series of hard pressure rollers, to deliver smooth, high-quality products of plastic, textile, or paper (Fig 1). Ensuring a consistent material thickness, however, depends on the ability to monitor, and maintain, a precise gap between rollers. This application note describes a quick and easy means for roller gap measurement. Problem Establishing a roller gap and checking for parallelism across roller width can be a slow and cumbersome procedure. Manual measurement requires multiple sized feeler gauges which can introduce errors. Misinterpreting feeler gauge drag, [...]

Testing for Connector Failure Due to Vibration or Shock

Testing for Connector Failure Due to Vibration or Shock Mobile Communications Equipment Needs Reliable Connectors That Will Not Disconnect with Shock or Vibration Introduction A large multinational company approached MTI to provide a sensor capable of measuring displacement that also wouldn’t load the target (connector). Shock and vibration testing would span 2-15G and the target connectors were very small. Application MTI’s 2100 optical displacement sensor system is ideal for this kind of application because very small probes can be used and they measure displacement via reflected light. Of course, reflected light does [...]

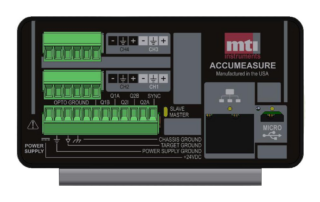

Connecting Encoders to MTI’s Digital Accumeasure

Connecting Encoders to MTI's Digital Accumeasure MTI's Digital Accumeasure D has the ability to accept one or two digital quadrature encoders. The encoders can be linear slide-type or rotary. Digital encoders allow for tracking the position of capacitive probes such that you can synchronize a probe's position with the probe's displacement data. Two common examples are: Rotary shaft runout: shaft (radial) displacement vs. angular encoder position X/Y position of probes measuring wafer thickness (map wafer thickness) Accumeasure software (basic and measurement) allows the display of instantaneous encoder counts as well as probe displacement data; however, [...]

Foam Density Measurement: Capacitance Sensors vs. Nuclear Gauges

Foam Density Measurement: Capacitance Sensors vs. Nuclear Gauges Foam Density Measurement Manufacturing EV Battery Production Thickness, Distance This application note from MTI Instruments compares two technologies for measuring foam density: capacitance sensors and nuclear gauges. It examines the basic operating principles of each technology and explains why capacitance measurement is recommended for in-line measurement during foam manufacturing. Capacitance Sensors Capacitive probes are non-contact devices that use electric fields to measure foam density. In combination with a thickness value, a density measurement may be calculated. These probes consist of a capacitance [...]

ADDING A DIGITAL PANEL METER TO MTI ANALOG OUTPUT PRODUCTS

How To Use Digital Displays with Analog OutputsMTI Microtrak 3 Lasers and some of our Accumeasure amplifiers such as the Accumeasure 9000 only have analog outputs. If you wish to add a digital display, then the Lascar Panel pilot © makes a nice cost effective (~ $110) addition – Fig 1. These Digital panel meters have both 1 & 2 channel display capability and the user can customize the display with a variety of interesting formats. The meter can operate off 4-30VDC which is compatible with the MT-3 power supply and the panel meter inputs can handle 0-10V which is compatible with [...]

PRECISION LASER MEASURING TOOLS

If you are looking for high quality, reliable precision laser measurement tools and devices then you are in the right place. MTI Instruments is a manufacturer of precision tools, systems and solutions for clients requiring the precise measurement and control of products and processes, and for the development and implementation of automated manufacturing, assembly, and complex machinery operation. Our product solutions are used in: Engine vibration analysis systems for military and commercial aircraft applications Industrial manufacturing/production markets Research, design and process development market. Non-Contact Measurement Turbine Balancing & Vibration Analysis Semiconductor/Solar Metrology Systems Signal Generator Applications When it comes [...]

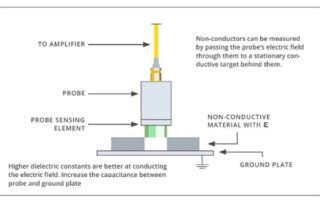

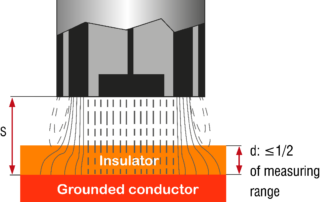

Thickness Measurement of Dielectric Materials

Thickness Measurement of Dielectric Materials Manufacturing EV Battery Production Thickness, Distance --- Description --- Introduction Many applications, both in manufacturing and research, require precise material thickness measurements. This becomes especially difficult if the material is moving, is non conductive and/or translucent to clear. The specifics of your application may make accurate measurements difficult; many circumstances prohibit contact measurement, and make laser measurements difficult or impossible, for example with thin clear materials such as glass, sapphire, plastic . In cases such as these, capacitance measurement provides a highly accurate and cost-effective solution. [...]

Windshield Manufacturing

Industry Automotive Applications Oil Film Measurement Type Level Description In order to maintain proper profile and thickness within a glass furnace the extrusion plate spacing must be maintained at a predetermined gap. Unfortunately, due to process changes and temperature swings this gap can fluctuate significantly in short periods of time. This variation causes the glass thickness to change (check out our glass thickness measurement devices to accurately measure thickness), producing uneven temperature gradients and creating potentially weak glass panels. To control this critical parameter the manufacturing process requires automated active feedback [...]

Comparing Non-Contact Sensors: Capacitive vs. Eddy Current Sensors

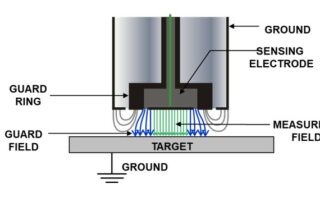

Comparing Non-Contact Sensors: Capacitive vs. Eddy Current Sensors Comparing Non-Contact Sensors: Capacitive vs. Eddy Current Sensors Manufacturing EV Battery Production Thickness, Distance This application note from MTI Instruments compares two types of non-contact sensors: capacitive and Eddy current. It describes their basic operating principles, includes a quick comparison table, and offers recommendations for use. Capacitance Sensors: Basic Operating Principles Capacitive probes use electric fields to measure the distance from the sensor face to the target surface. A guard ring around the capacitive sensor in the probe steers the direction of [...]

GRINDING PROCESS

A cylindrical grinding process finishes most wheel spindle surfaces. It is essential that this grinding process leave a surface finish that is smooth and free of defects with minimal runout. No grinder produces a perfect surface. Grinder wheel runout, improperly dressed wheels and fixture vibrations can cause chatter on the spindle surface finish. Chatter is a series of microscopic, repetitive imperfections, or waves, in the surface of the material being machined. The required production environment sensor must have small spatial resolution, high frequency response and large standoff distance for easy loading and unloading of parts. Additionally, the measurement accuracy had to [...]