Blogs

Case-In-Point: Step Height Measurement (Thickness) of Copper Foil or EV Battery Film on a Roller Rig

Step Height Measurement (Thickness) of Copper Foil or EV Battery Film on a Roller Rig Leverage MTI Instruments’ digital Accumeasure system to measure the thickness of the material used as anode and cathode plates in rechargeable Li-Ion battery cells Many roll-to-roll finishing processes typically use a calender, or series of hard pressure rollers, to deliver smooth, high-quality products of plastic, textile, or paper (Fig 1). Ensuring a consistent material thickness, however, depends on the ability to monitor, and maintain, a precise gap between rollers. This application note describes a quick and easy means for roller gap measurement. Introduction [...]

WAFER MEASUREMENT – UNGROUNDED

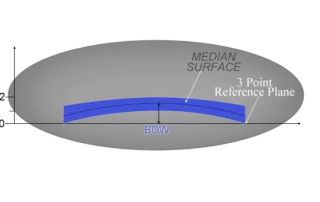

Industry Semiconductor Applications Wafer Measurement – Ungrounded Measurement Type Metrology Description MTI Instruments Inc. has developed a thickness measurement device that eliminates the effect of varying target conductivity. Called the Push-Pull probe, it’s a unique version of the AccumeasureTM amplifier series. This special design provides accurate surface information for wafer bow and warp. Bow is the deviation of the center point of the median surface of a free, un-clamped wafer from the median surface to the reference plane. Where, the reference plane is defined by three corners of equilateral triangle. This [...]

PHOTOLITHOGRAPHY USING CAPACITANCE SENSORS

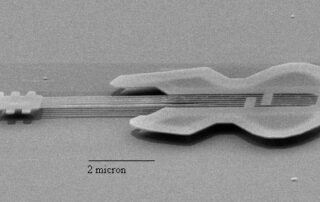

Industry Semiconductor Applications Lithography Optics Position Focus Measurement Type Positioning Description When it comes to photolithography, how accurate are our sensors? Photo by D. Carr and H. Craighead, Cornell - The world’s smallest guitar is 10 micrometers long — about the size of a single cell — with six strings each about 50 nanometers, or 100 atoms, wide. Made by Cornell University researchers from crystalline silicon, it demonstrates a new technology for a new generation of electromechanical devices. Even the world’s smallest guitar’s 2 micron [...]

Case-In-Point: High-Accuracy Capacitive Thickness Measurement Optimizes Li-Ion EV Battery Plate Qualities

High-Accuracy Capacitive Thickness Measurement Optimizes Li-Ion EV Battery Plate Qualities EV Battery manufacturers need to measure EV battery plate thickness with a high degree of precision (repeatable <2um accuracy and resolution) to optimize manufacturing efficiencies while maintaining uniform cell capacity and minimizing waste. The MTI Accumeasure System provides an effective means of monitoring plate thickness achieving sub 2um accuracy with high repeatability Introduction The rapidly expanding demand for electric vehicles is driving advances in the production of rechargeable cells that comprise the first stage in the composition of EV battery packs. Individual Li-Ion cells are combined to [...]

MTI App Note: Step Height Measurement (Thickness) of Copper Foil or EV Battery Film on a Roller Rig

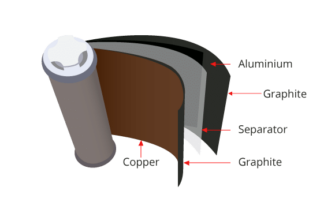

Step Height Measurement (Thickness) of Copper Foil or EV Battery Film on a Roller Rig Leverage MTI Instruments' digital Accumeasure system to measure the thickness of the material used as anode and cathode plates in rechargeable Li-Ion battery cells Introduction Figure 1. Simplified structure of a Li-Ion battery cell This white paper describes, in detail, how Non-Contact Measurement systems can be used to measure the thickness of the material used as anode and cathode plates in a rechargeable Li-Ion battery Cell. Figure 1 describes the elements comprising a Li-Ion battery cell. The cathode is comprised of [...]

MTI Application Note: How to Achieve <1um Accuracy When Measuring Roller Gap

How to Achieve <1um Accuracy When Measuring Roller Gap Roller Gap Measurement with MTI Digital Accumeasure Capacitive Probes Many roll-to-roll finishing processes typically use a calender, or series of hard pressure rollers, to deliver smooth, high-quality products of plastic, textile, or paper (Fig 1). Ensuring a consistent material thickness, however, depends on the ability to monitor, and maintain, a precise gap between rollers. This application note describes a quick and easy means for roller gap measurement. Problem How to measure the small gap between rollers to keep track of product thickness. Typically, it’s not possible to [...]

MTI Application Note: Security of Flight Doors Improved Through Use of MTI-2100 Fotonic Sensor

Security of Flight Doors Improved Through Use of MTI-2100 Fotonic Sensor Increased Safety & Reliability for Aircraft Cockpit Doors NTSB safety records point to numerous incidents involving cockpit door locking/unlocking mechanisms, either accidentally opening/closing or not operating fact enough upon command. Learn how one key industry supplier leveraged Fotonic Sensors to increase reliability and safety for their door locking mechanisms. Introduction Figure 1. Example of a typical cockpit door strike NTSB safety records point to numerous incidents involving cockpit door locking/unlocking mechanisms, either accidentally opening/closing or not operating fast enough upon command. In the assembly [...]

MTI Case-In-Point: Gap Monitor Keeps Wind Turbines Running

Gap Monitor Keeps Wind Turbines Running System helps operators minimize downtime and protect against catastrophic failure Introduction Wind turbine production has been steadily increasing to meet growing demand for renewable energy. As power outputs and the number of installations climb, maintenance becomes ever more critical. Operators want to minimize downtime and protect against catastrophic failure. The ability to predict when maintenance will be required can go a long way to ensure these goals are met. Challenge A leading manufacturer of wind turbine power generators approached MTI for critical gap monitoring sensors. Specifically, the company wished to [...]

MTI Application Note: Testing for Connector Failure Due To Vibration or Shock

Testing for Connector Failure Due to Vibration or Shock Mobile Communications Equipment Needs Reliable Connectors That Will Not Disconnect with Shock or Vibration Introduction A large multinational company approached MTI to provide a sensor capable of measuring displacement that also wouldn’t load the target (connector). Shock and vibration testing would span 2-15G and the target connectors were very small. Application MTI’s 2100 optical displacement sensor system is ideal for this kind of application because very small probes can be used and they measure displacement via reflected light. [...]

A Comprehensive Guide to Non-Contact Sensors and Their Applications

A Comprehensive Guide to Non-Contact Sensors and Their ApplicationsSensors, both contact and non-contact, are crucial devices that allow the monitoring, detection, and reaction to conditions in an environment or within a process or piece of equipment. While myriad types of sensors exist and are designed to monitor varying conditions, all of them can be characterized as being one of two types — contact sensors and non-contact sensors. We’ll focus on the latter, diving into different technologies, types, and applications of non-contact sensor technology; but first, let’s explore what differentiates contact and non-contact sensors.Contact vs. Non-Contact Sensors: What’s the Difference?Measuring, monitoring, [...]