Blogs

Vitrek Scratchoff Promotion Winner!

[wufoo username="freibergs" formhash="m11t7ikx0dqp3sa" autoresize="true" height="1089" header="show" ssl="true"] Congratulations on being an instant winner in the Vitrek Scratchoff Promotion! Please complete this form to register your winning ticket! Your Vitrek Polo Shirt will be delivered in 3-4 weeks. In addition, you will automatically be entered into our quarterly "Big Prize" drawing where you can win a Smart TV! If you have any questions about the promotion please contact [email protected]. Void where prohibited by law. Promotion applies to US, Mexico & Canadian orders. Promotion may end at any time without notice. All form fields must be completed to receive [...]

Case-In-Point: High-Accuracy Capacitive Thickness Measurement Optimizes Li-Ion EV Battery Plate Qualities

High-Accuracy Capacitive Thickness Measurement Optimizes Li-Ion EV Battery Plate Qualities EV Battery manufacturers need to measure EV battery plate thickness with a high degree of precision (repeatable <2um accuracy and resolution) to optimize manufacturing efficiencies while maintaining uniform cell capacity and minimizing waste. The MTI Accumeasure System provides an effective means of monitoring plate thickness achieving sub 2um accuracy with high repeatability Introduction The rapidly expanding demand for electric vehicles is driving advances in the production of rechargeable cells that comprise the first stage in the composition of EV battery packs. Individual Li-Ion cells are combined to [...]

MTI App Note: Step Height Measurement (Thickness) of Copper Foil or EV Battery Film on a Roller Rig

Step Height Measurement (Thickness) of Copper Foil or EV Battery Film on a Roller Rig Leverage MTI Instruments' digital Accumeasure system to measure the thickness of the material used as anode and cathode plates in rechargeable Li-Ion battery cells Introduction Figure 1. Simplified structure of a Li-Ion battery cell This white paper describes, in detail, how Non-Contact Measurement systems can be used to measure the thickness of the material used as anode and cathode plates in a rechargeable Li-Ion battery Cell. Figure 1 describes the elements comprising a Li-Ion battery cell. The cathode is comprised of [...]

High Precision Portable Signal Generators and Calibrators: Everything You Need to Know

High precision portable signal generators are portable electronic devices that generate highly precise signals for testing, system calibration, sensor simulation, troubleshooting, and monitoring. Unlike the benchtop signal generators that are used in laboratories, these hand-held portable devices are designed to be used in the field. The best high precision portable signal generators are also rugged and NIST traceable, meaning that their manufacturer calibrates them to standards from the National Institute of Standards and Technology (NIST). In terms of cost, high precision portable signal generators are more expensive than less precise, lower-end devices that can be held in the hand; [...]

KineticSystems Partner Products

KineticSystems Partner Products Astronics Test Systems ActivATE Software Astronics Test Systems ActivATE Test Platform Development Environment All KineticSystems cPCI/PXI instruments are fully supported in the Astronics Test Systems ActivATE Test Platform Development Environment.The Astronics Test Systems ActivATE Test Platform is both a runtime and development environment for automatic test equipment and factory floor automation. ActivATE test software allows the test engineer to focus on software testing and not the test environment design.ActivATE test software has been used in both commercial and military applications with tremendous success. Deployed worldwide, this software has been used to test a wide range of units under [...]

Capacitance Probe System for Gap Measurement

This is a Legacy product. For information or support contact MTI Instruments at [email protected]. Capacitance Probe System for Gap Measurement Request Quote Download Data Sheet Bring capacitance accuracy, high-speed response, built in calibration and temperature stability to your manufacturing floor at a cost effective price point. Suitable for industrial deployment, this pre-calibrated capacitive gap sensor system provides highly accurate measurements to a grounded metal target. Capable of taking continuous or manual samples with analog or digital output for analysis or machine control. The large sample rate allows for insight into probe measurements [...]

Signal Conditioners

Signal Conditioning Data Acquisition & Control Products KineticSystems provides signal conditioning product solutions to meet demanding data acquisition and control requirements based on CompactPCI, PXI, and VXI standards. KineticSystems is a proud member of the PXI Systems Alliance and the VXI Bus Consortium. Data Acquisition & Control Products cPCI/PXI Signal Conditioners VXI Signal Conditioners

MTI Application Note: How to Achieve <1um Accuracy When Measuring Roller Gap

How to Achieve <1um Accuracy When Measuring Roller Gap Roller Gap Measurement with MTI Digital Accumeasure Capacitive Probes Many roll-to-roll finishing processes typically use a calender, or series of hard pressure rollers, to deliver smooth, high-quality products of plastic, textile, or paper (Fig 1). Ensuring a consistent material thickness, however, depends on the ability to monitor, and maintain, a precise gap between rollers. This application note describes a quick and easy means for roller gap measurement. Problem How to measure the small gap between rollers to keep track of product thickness. Typically, it’s not possible to [...]

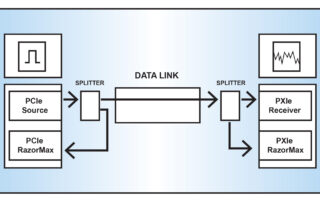

GaGe Application Note: Creating a Data Link Signal Integrity Test Platform

Creating a Data Link Signal Integrity Test Platform This application note describes how a manufacturer of data links utilizes GaGe Instruments’ PC-based high-speed data acquisition digitizers to perform production-level signal integrity testing. Data Link Device Testing The data link device under test (Figure 1) is characterized by comparing test signals that are input to the link with signals measured at the link output. Differences between these two test signals indicate a degradation by the link during transmission. The input and output test signals require sampling at 1 GS/s (GigaSample per second) with at least 14-bit vertical resolution. [...]

MTI Application Note: Security of Flight Doors Improved Through Use of MTI-2100 Fotonic Sensor

Security of Flight Doors Improved Through Use of MTI-2100 Fotonic Sensor Increased Safety & Reliability for Aircraft Cockpit Doors NTSB safety records point to numerous incidents involving cockpit door locking/unlocking mechanisms, either accidentally opening/closing or not operating fact enough upon command. Learn how one key industry supplier leveraged Fotonic Sensors to increase reliability and safety for their door locking mechanisms. Introduction Figure 1. Example of a typical cockpit door strike NTSB safety records point to numerous incidents involving cockpit door locking/unlocking mechanisms, either accidentally opening/closing or not operating fast enough upon command. In the assembly [...]