Blogs

End of Life/Support

End of Life/Support This is a notice for owners of older versions of PBS products. Read below for more details. Valued PBS customers and partners: MTI Instruments prides itself on providing consistent, quality experiences for our customers. We recognize the importance of having products you can rely on to perform required functions consistently and accurately. As with any aging system, components become obsolete, parts become subject to wear and tear, software becomes vulnerable to cybersecurity risks, and older operating systems are incompatible with current operating environments. To that end, starting on August 1st, 2021, we [...]

Piezo Stage Positioning

Piezo Stage Positioning Consumer Electronics Piezo Stage Positioning Description Positioning stages using piezoelectric stack actuators (PEA) have very high resolution. However, it is difficult to achieve precise dynamic motion tracking using traditional linear controllers such as PID due to the inherent hysteresis nonlinearity of piezoelectric materials and the phase lag associated with such controllers. Capacitance Sensors are ideal for measuring the actual piezo stage position and correcting for the inherent nonlinearity through closed loop feedback. They have the stability, bandwidth and high resolution needed to do the job. Several of [...]

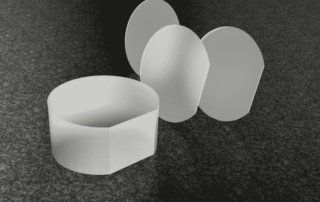

Glass Thickness

Glass Thickness Consumer Electronics Glass Thickness Thickness Description Did you know that glass thickness can be measured with a capacitance probe? You will need some equipment: Digital Accumeasure D200 ASP-2500-CTA Dielectric probe (The capacitance probe has a sensing area of 11.25 mm) Range extension = 3X, 10Hz filter Introduction:  An industrial glass fabricator needed a way to determine the thickness of glass, before cutting it to shape and coating it. The glass sample was marked with indices to find the measuring points. The sample center point -5- thickness was checked with [...]

Electronics Parts Profiling

Electronics Parts Profiling Consumer Electronics Electronics Parts Profiling Thickness Description MTI's 2D laser sensors can be used to scan 3D profiles of items such as printed circuit boards to verify all the parts are installed, making sure parts don’t exceed certain heights or that the part is present. You can even plot or examine the image intensity profile of the 2D sensor which yields a monochromatic image of the target and this can be used with OCR software or barcode software to recognize product codes, check if labels are present [...]

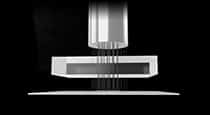

Height Gap Of Inkjet Printers

Height Gap Of Inkjet Printers Consumer Electronics Height Gap Of Inkjet Printers Positioning Description Introduction:  Inkjet printers require a certain distance between the inkjet print head and the paper. If the distance is set incorrectly, the printed images get blurry. Current state of the art printers have the print head nozzles built right into the bottom of the ink reservoir (B) as shown below. When the ink cartridge is installed in the printer, the inkjet nozzles (made out of silicon) essentially become a grounded target through the connections shown at [...]

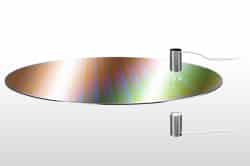

Wafer Measurement – Ungrounded

Wafer Measurement - Ungrounded Semiconductor Wafer Measurement - Ungrounded Metrology Description MTI Instruments Inc. has developed a thickness measurement device that eliminates the effect of varying target conductivity. Called the Push-Pull probe, it’s a unique version of the AccumeasureTM amplifier series. This special design provides accurate surface information for wafer bow and warp. Bow is the deviation of the center point of the median surface of a free, un-clamped wafer from the median surface to the reference plane. Where, the reference plane is defined by three corners of equilateral triangle. This [...]

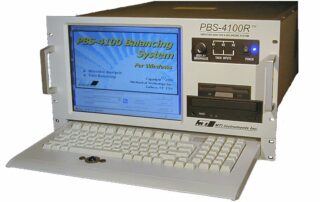

MRO NBAA 2022 Show Page

Two New Product Introductions at MRO Americas and NBAA Maintenance Conference Redefining a premier product family to improve jet turbine vibration analysis and balancing Join us at the MRO Americas show in Dallas, TX on April 26-28, or the NBAA Maintenance Conference in San Antonio, TX on May 3-5 to experience the MTI PBS family of products and see how our two new products can help your company with: Expanded functionality Improved usability focused on ease of learning and ease of use Faster performance Greater portability Better [...]

Wafer Thickness, Bow, Warp And TTV

Semiconductor Wafer Thickness, Bow, Warp And Ttv Surface Description Thickness Measurement ASTM F657: The distance through a wafer between corresponding points on the front and back surface. Thickness is expressed in microns or mils (thousandths of an inch). Total Thickness Variation (TTV) ASTM F657: The difference between the maximum and minimum values of thickness encountered during a scan pattern or series of point measurements. TTV is expressed in microns or mils (thousandths of an inch). Figure above shows a wafer placed between two non-contact measurement probes. By monitoring changes [...]

Tape Cartridge Movement

Tape Cartridge Movement Semiconductor Tape Cartridge Movement Positioning Description Researchers are presently working on drives with track widths in the 5 to 1 micron region. For these small widths, tape wander, properly called Lateral Tape Movement (LTM), must be less than 1 micron. This is because the track following head always lags the moving target and produces a position error signal. If the position error signal gets to be larger than about 1/10 the track width, the track cannot be read. However, it follows that the smaller the LTM, the smaller [...]

Wafer QA/QC After Slicing And Polishing

Wafer QA/QC After Slicing And Polishing Semiconductor Wafer Qa/Qc After Slicing And Polishing Surface Description Introduction: When wafers are sliced up with wire saws, they are measured to make sure they are within the specified thickness, with minimal bow, warp, and TTV. After initial measurement, they are sorted and sent for polishing. Since polishing removes material and smoothes out the rough surfaces they need to be measured again to ensure they meet thickness guidelines and quality standards. Solution: MTI Instruments manufactures multiple systems to perform thickness measurements. From semi automated Proforma [...]