Blogs

Capacitance Sensing vs. Strain Gauge Sensing Application Note

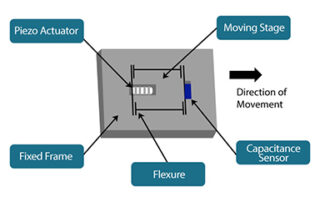

Capacitance Sensing vs. Strain Gauge Sensing Application Note Capacitance probes that are embedded in piezo flexure stages can provide significantly greater accuracy than strain gauges. Although some minor mounting modifications are required, capacitance probes with picoscale positioning provide higher linearity, greater long-term stability, and better direct measurement. Capacitance sensors cost more, however, and are limited by sensing distance. Therefore, strain gauge sensors remain a good choice for applications where cost is a consideration, sensing distances are larger, and high resolution or high accuracy are required. In a recent application note, MTI Instruments examines the differences between capacitance probes and [...]

Using Capacitance Sensors for Non-Conductive Material Measurement

Non-Conductive Material Measurement with Capacitance Sensors Capacitance sensors are non-contact devices that can be used to obtain position, thickness, and dynamic measurements with a high degree of precision, accuracy, and resolution. Capacitive measurement is used with electrically-conductive materials such as metals but can also be used to measure non-conductive materials such as glass, sapphire, and many plastics. Even if a non-conductive material is relatively inexpensive (such as closed cell foam), manufacturers want to avoid errors that can result in significant waste across high volumes. Importantly, capacitance measurement is also used with semi-insulating materials such as gallium arsenide (GaAs) and [...]

Semiconductor Wafer Lapping and Displacement Measurement

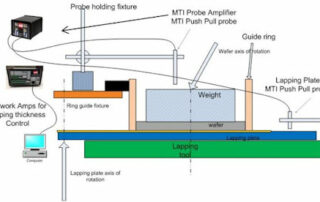

Semiconductor Wafer Lapping and Displacement Measurement Semiconductor Semiconductor Wafer Manufacturing Displacement Description Semiconductor Wafer Lapping and Displacement Measurement This application note explains how MTI’s Accumeasure technology was used with a lapping machine to measure displacement (wafer material removal) and determine the new semiconductor wafer thickness. Changes in electrical capacitance (displacement) were measured and then directly converted into a 24-bit digital reading to obtain precise digital thickness measurements. During lapping, a wafer of known start thickness is placed on a rotary lapping table. The backside of the wafer faces downward and [...]

Why Demand for SiC Wafers is Hot and Durable

Why Demand for SiC Wafers is Hot and Durable Pardon the pun, but SiC wafers are a hot item for high-temperature applications. Silicone carbide (SiC), a semiconductor containing both silicon and carbide, withstands temperatures up to 2700°C. Carborundum, as this durable ceramic is also known, finds additional applications in bulletproof vests, extrusion dies, sandpaper, and high-performance disc brakes. In electronics, SiC materials are used with light-emitting diodes (LEDs) and detectors. In the semiconductor industry, a market where interest is red-hot, SiC wafers are used in electronic devices that operate at high temperatures, high voltages, or both. Examples include electric [...]

Wafer Stress Analysis Using the 300iSA

Wafer Stress Analysis Using MTI Instruments Proforma 300iSAWafer processing involves several stages that may translate into mechanical alterations. Sometimes these alterations can cause deformities that render the wafer either unusable or that put it marginally close to not being usable. To determine this, stress analysis can be used.The Proforma 300iSA wafer characterization tool provides a software capability in which a wafer can be analyzed prior to processing and then after processing. The tool then evaluates how the wafer changed and hence, provides the resulting stress analysis.The software expects the customer to provide the material elasticity constants and to define them [...]

Weathering the storm: Keys to resiliency in MRO

Weathering the storm: Keys to resiliency in MRO By Ken Ameika It’s no secret that COVID-19 has adversely affected the airline industry, and consequently the MRO and test cell markets. But the impacts are nuanced. Commercial aircraft utilization is way down; meanwhile, freight carrier business is expanding markedly. Operators are spending less; but they still have needs, which often require quick turnaround. It’s been hard for many. But there’s good news: COVID provided lessons that we can all use to make our businesses, or our careers, more resilient to the next major disruption. Diversify Your Business Commercial passenger traffic—or [...]

Capacitance Probes vs. Strain Gauges in Piezo Flexure Stages

Capacitance probes with pico-positioning sensors can be embedded in piezo flexure stages. With minor mounting modifications, these non-contact probes provide significantly greater accuracy than strain gauges. Piezo flexure stages are positioning devices with a high degree of resolution. These motion stages contain a piezoelectric actuator that converts an electrical signal into displacement based on the reverse piezoelectric effect, which is the ability of a piezo electric material to elongate when a voltage is applied. When a voltage (e.g., 0-150 VDC) is applied to the actuator, the stage moves in proportion to the applied voltage. Yet, the exact position remains [...]

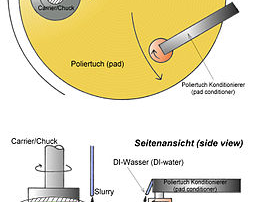

CMP and Capacitance-Based Semiconductor Wafer Measurement

Chemical mechanical polishing (CMP) uses chemical oxidation and mechanical abrasion to selectively remove material from semiconductor wafers in order to achieve very high levels of planarity. The planarity, or flatness, of these wafers is important for optical lithography, a microfabrication technique that produces integrated circuits (ICs) by transferring a geometric pattern from a photomask to a light-sensitive chemical photoresist. Also known as photolithography or UV lithography, optical lithography can produce a geometric pattern on a thin film or directly onto the substrate. Semiconductor Wafer Measurements: Flatness and Shape During optical lithography, variations in wafer flatness must be smaller than [...]

MTI Instruments Announces Newest Addition of the PBS-4100+ Portable Vibration and Balancing System

Learn More About PBS-4100+ Gen4 [/fusion_builder_row][/fusion_builder_container] MTI Instruments Announces Newest Addition of the PBS-4100+ Portable Vibration and Balancing System; Continuing its Industry Leading Excellence in Aircraft Engine Maintenance Systems The fourth-generation iteration of MTI Instruments’ engine vibration analysis and balancing system is more mobile than ever, while maintaining the highest standards in the industry for commercial aviation ALBANY, N.Y., April 27, 2021 /PRNewswire/ — MTI Instruments, Inc. (“MTI Instruments”), a wholly-owned subsidiary of Mechanical Technology, Incorporated (NASDAQ: MKTY), long known as the creators of industry leading aircraft engine maintenance diagnostic systems, continues their impressive legacy with [...]

MTI Instrument’s PBS ROI Calculator: See How Much Money You Can Save

Ensuring the proper operation of your aircraft engine is essential to complying with manufacturers guidelines for the safety and longevity of the aircraft. Ensuring engines are not operating outside acceptible vibration limits and operating optimally isn't just smart, it is vital to your business. Excessive engine vibration can lead to cracked turbine, fan and compressor components potentially leading to catastrophic failure. The costs of catastrophic engine failure due to an unbalanced engine can measure in the millions of dollars. As airlines push to get more and more life out of their aging fleets, the need to properly maintain the [...]