Vitrek White Papers

Articles

Vitrek in the News…

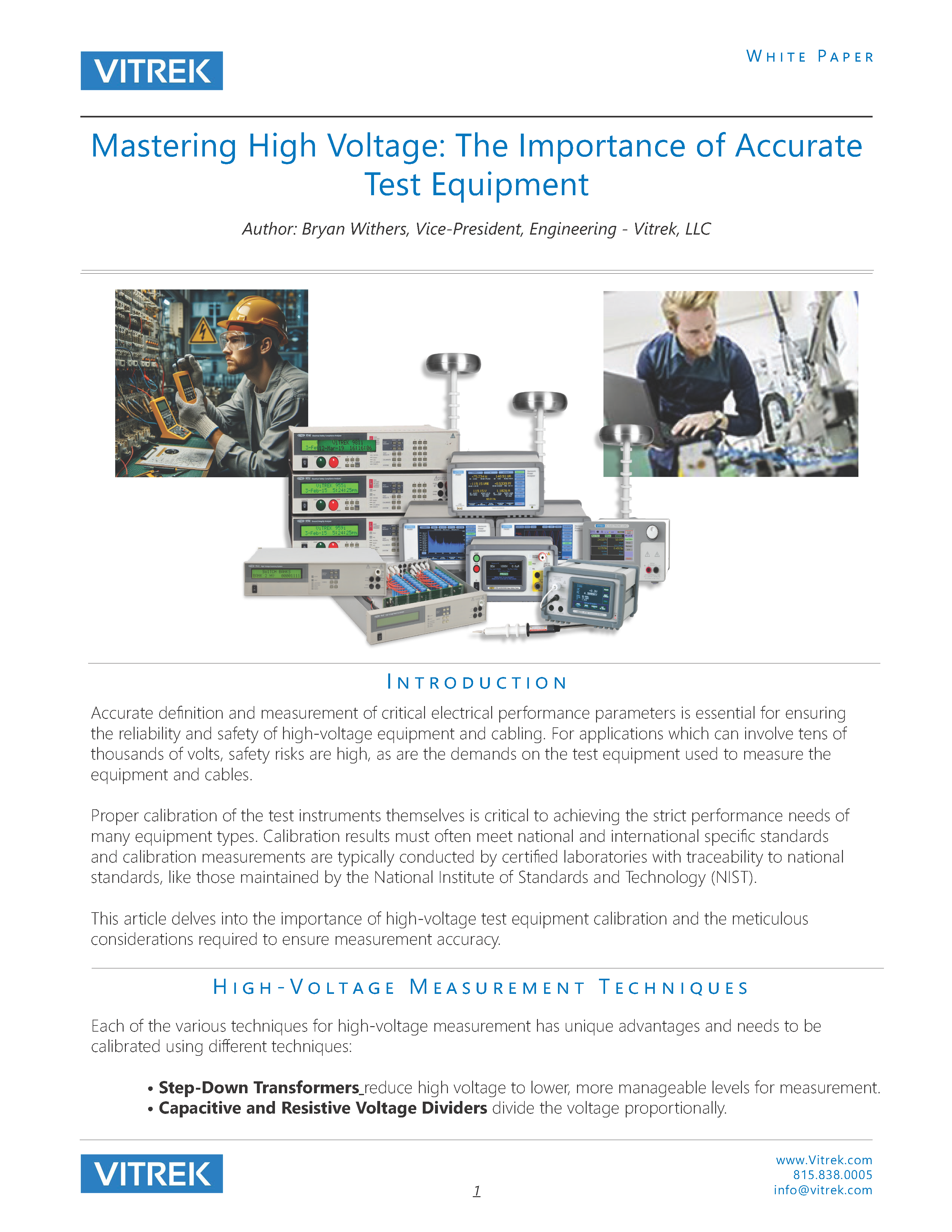

Whitepaper: Mastering High Voltage: The Importance of Accurate Test Equipment

Introduction

Accurate definition and measurement of critical electrical performance parameters is essential for ensuring the reliability and safety of high-voltage equipment and cabling. For applications which can involve tens of thousands of volts, safety risks are high, as are the demands on the test equipment used to measure the equipment and cables.

Proper calibration of the test instruments themselves is critical to achieving the strict performance needs of many equipment types. Calibration results must often meet national and international specific standards and calibration measurements are typically conducted by certified laboratories with traceability to national standards, like those maintained by the National Institute of Standards and Technology (NIST).

This article delves into the importance of high-voltage test equipment calibration and the meticulous considerations required to ensure measurement accuracy.

High-Voltage Measurement Techniques

Each of the various techniques for high-voltage measurement has unique advantages and needs to be calibrated using different techniques:

-

Step-Down Transformers reduce high voltage to lower, more manageable levels for measurement.

-

Capacitive and Resistive Voltage Dividers divide the voltage proportionally.

-

Series Resistance (Microampere Measurement): Measures current through a high resistance in series with the voltage source.

-

Analog Style Measurement Devices:

-

Sphere Gaps measure the voltage by observing the breakdown voltage between two spheres.

-

Electrostatic Measurement quantifies the electrostatic force between two plates.

-

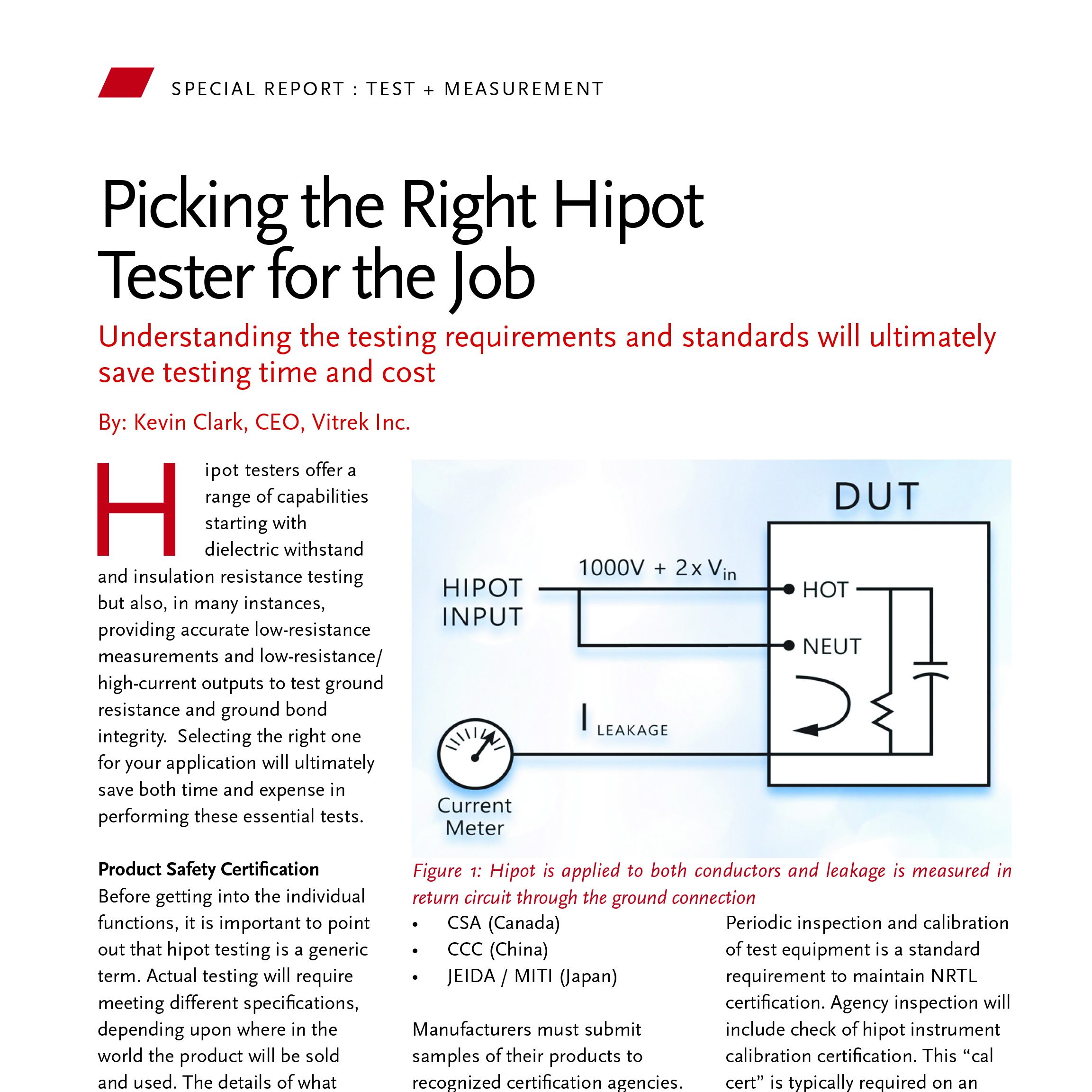

Figure 1. Many types of equipment are used for high-voltage measurement.

Why Measure High Voltage?

Measuring high voltage is increasingly important as technology advances. High-voltage systems reduce current carrying requirements and minimize energy loss. Also, in many cases, voltage values determine system performance. This means the voltage sources must be accurate and reliable in order to meet systems specifications. Also, monitoring systems need to be in place to ensure that the systems perform reliably from end-to-end and year-to-year.

High-Voltage Applications by Industry

High voltage, defined here as 1 kV to 150 kV (AC or DC), is used across various fields, including:

-

Analytical Instruments: Mass spectrometers and photomultiplier tubes.

-

Defense and Aerospace: Radar systems, CRT displays, and flight simulators.

-

Homeland Security: Baggage inspection and explosive detection equipment.

-

Inspection and Non-Destructive Testing: Systems that ensure the integrity of materials and structures.

-

Manufacturing Processes: Like electron beam welding and electrostatic coating applications.

-

Medical and Biotechnology: X-ray and radiographic equipment.

-

Research Laboratories: Products like detectors, accelerators other large scale analyzers.

-

Semiconductor Equipment: Essential for ion implantation and sputtering processes.

-

High Voltage Power Supplies: Fundamental in many industrial applications.

-

RF Generators and Matching Networks: Used in telecommunications and broadcasting.

-

Power Distribution: Critical for corona detection and cable insulation testing in electrical cables and harnesses be they in utility networks, manufacturing plants or campuses.

Accurate high-voltage measurement is essential in these sub-systems to ensure operational efficacy and safety.

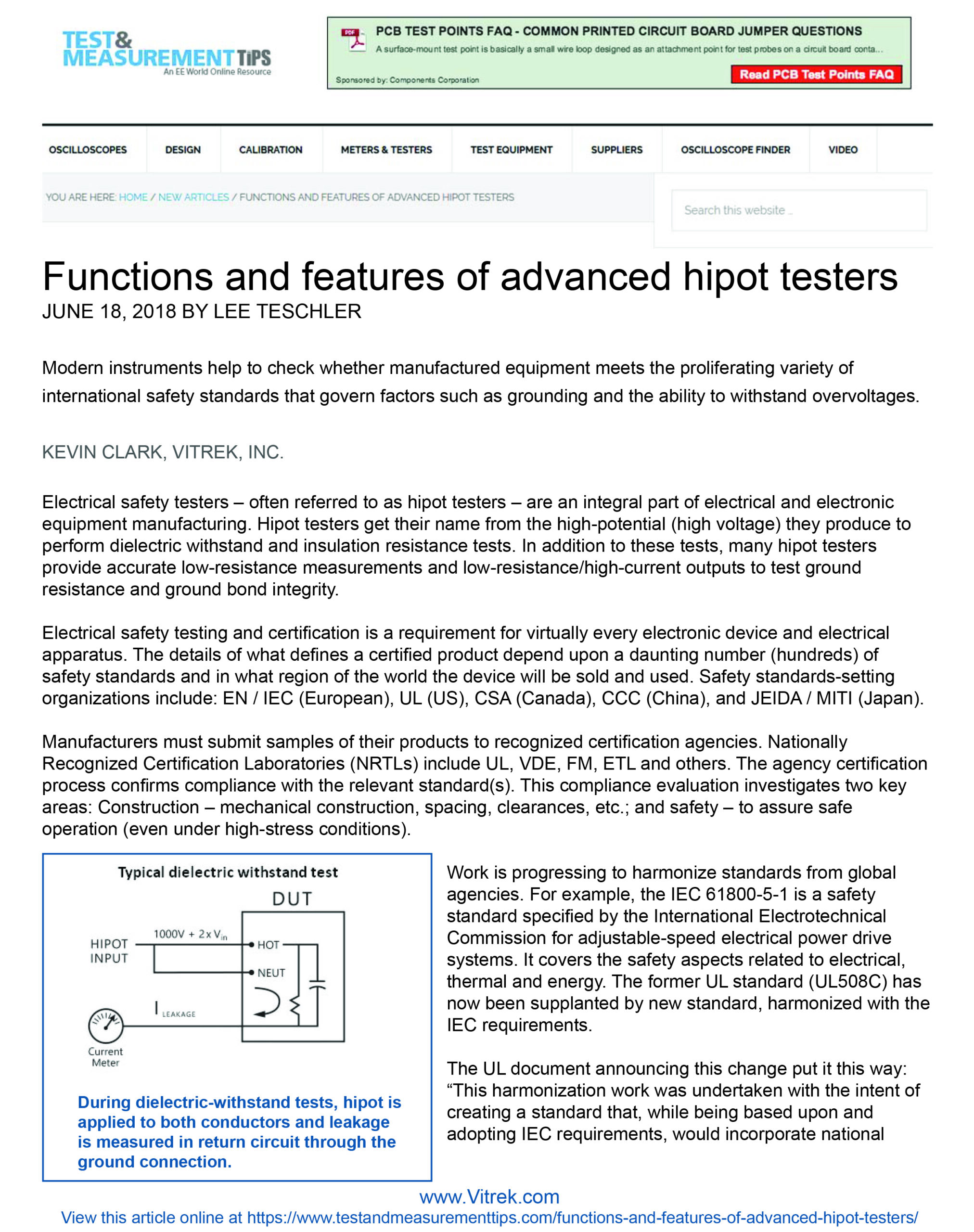

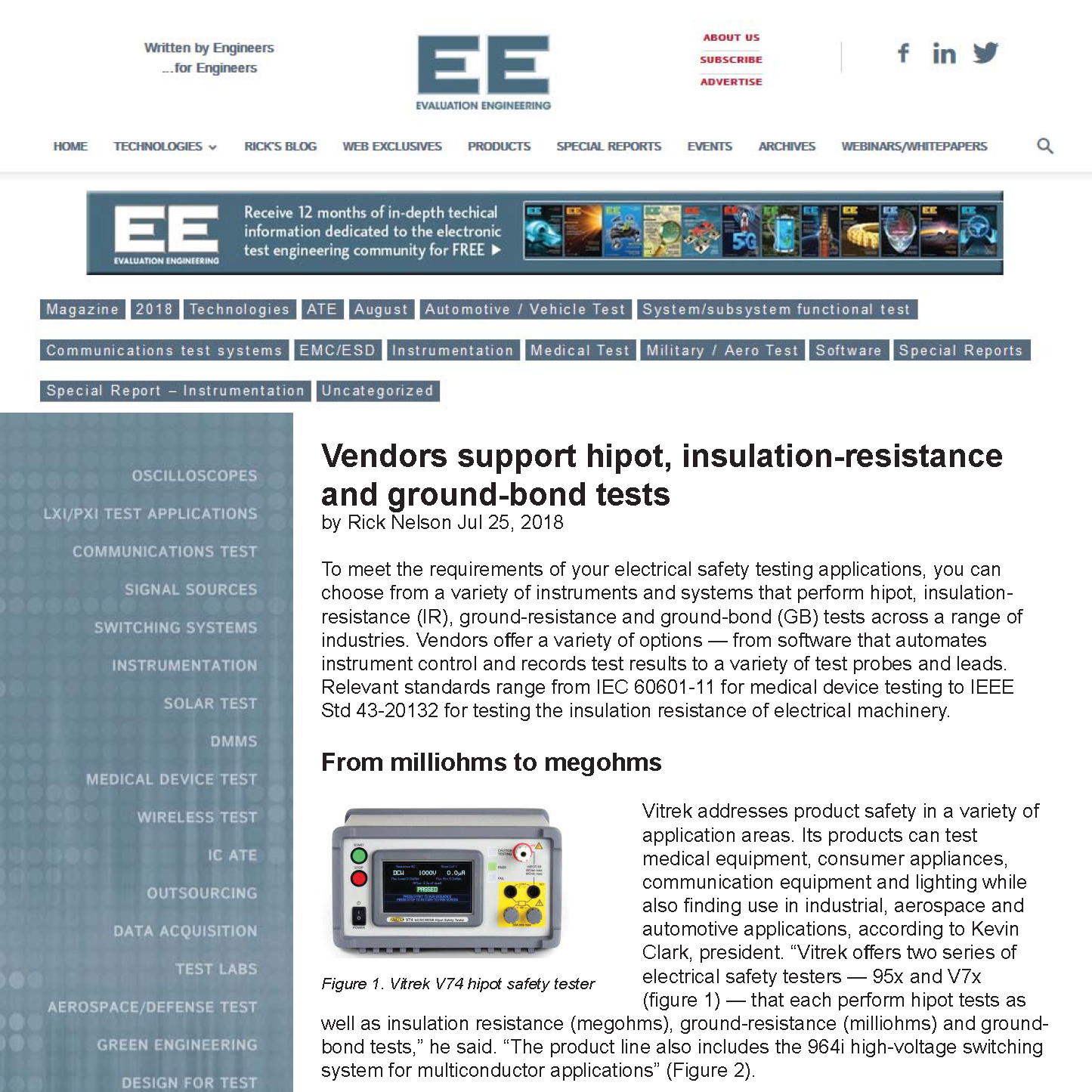

Devices requiring high-voltage measurements include:

-

Hipot Testers: Ensure the integrity of electrical insulation.

-

X-Ray Power Supplies: Validate performance for medical and industrial imaging.

-

Ion Implantation Systems: Regulate electrical systems for precise particle acceleration.

-

Energy Transmission Sub-Stations: High voltages in power grids enhance efficiency and reduce losses.

Safety Considerations

Calibrating high voltages is important for safety considerations:

-

Establishing appropriate earth ground conductivity prevents dangerous ground loops.

-

Ensuring sufficient clearance avoids unintended flashovers.

-

Proper barrier positioning protects people from high voltage areas under all conditions.

-

Means to discharging stored energy in voltage systems ensures safe adjustments.

-

Following Manufacturer Guidelines: Adherence to recommended practices minimizes risk.

High-Voltage Test Equipment Calibration

Calibration Standards and Accreditation

ISO/IEC 17025:2017 outlines the general requirements needed for calibration and test laboratories to be deemed technically competent to perform calibrations. Additionally, standards like ANSI/NCSL Z540-1-1994 are also recognized in the industry by defining measurement uncertainty criteria. Accredited labs undergo

regular assessments to maintain their certifications. These ensure that their procedures, environment, and personnel meet high standards of competence.

Ensuring Measurement Uncertainty

When calibrating high-voltage test equipment, it’s essential to account for all sources of measurement uncertainty, including:

-

Equipment Accuracy and Precision — Every measuring instrument has a specified accuracy, often expressed as a percentage of the reading or a fixed value. Precision, on the other hand, refers to the instrument’s ability to produce consistent readings over repeated measurements. Regular calibration ensures that both accuracy and precision are maintained, aligning instrument performance with its specified tolerances.

-

Signal Type and Frequency — High voltage measurements can be affected by the type of signal (AC or DC) and its frequency. AC signals, especially at high frequencies, can introduce additional errors due to reactive components in the measurement system. It is crucial to ensure that the measurement accounts for this reactivity so that its accuracy is maintained.

-

Calibration Procedures — Calibration involves comparing the instrument’s measurements to a known standard by making necessary adjustments. This process must be performed in controlled environments to minimize external influences. Calibration intervals depend on the instrument’s usage and the criticality of its measurements. Optimal intervals are usually recommended by the manufacturer.

-

Environmental Effects — Environmental conditions such as temperature, humidity, and altitude can significantly impact measurement accuracy. For instance, temperature fluctuations can cause expansion or contraction of materials, affecting the physical dimensions of components and thereby the measurement. Humidity can influence the conductivity and dielectric properties of insulating materials, while altitude changes can alter the air density, affecting high-voltage discharge characteristics.

-

Cabling and Connections — High-quality cables and secure connections are essential for accurate high-voltage measurements. Poor connections can introduce resistance, leading to voltage drops and inaccurate readings. Additionally, cables should be chosen based on their voltage rating and insulation properties to prevent leakage currents and ensure safety.

-

External Influences — Uncontrolled variables, such as EMI and corona discharges, can introduce significant errors in high-voltage measurements. EMI can be mitigated by using shielded cables and maintaining proper grounding. Corona discharge, caused by ionization of the air around conductors, can be reduced by using smooth, rounded connections and avoiding sharp points that can concentrate the electric field.

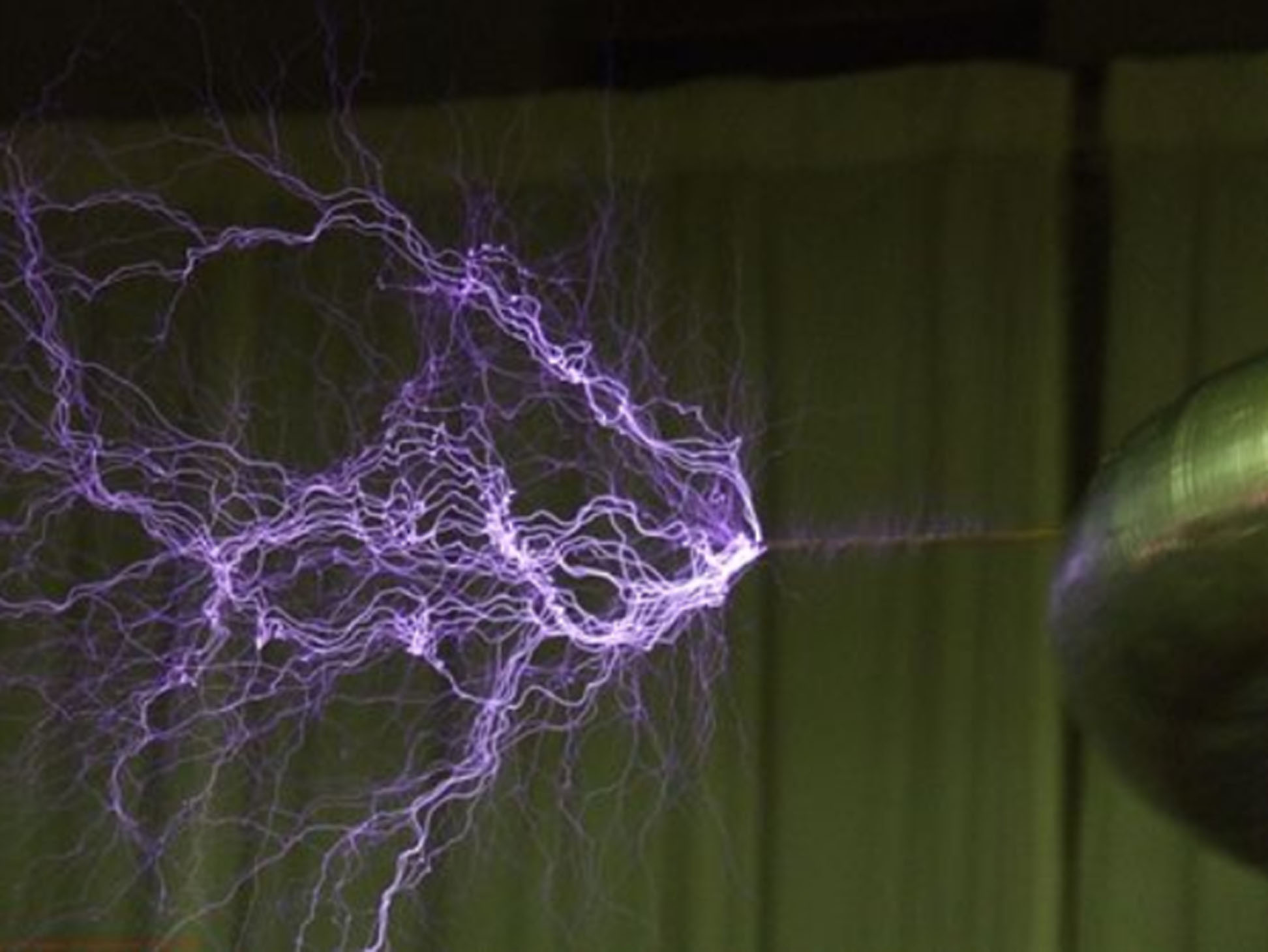

Corona and Connections

Corona discharge is a common source of error in high-voltage measurements. It occurs when an electrical discharge ionizes the surrounding air, often at sharp points or within air gaps in insulation. To minimize corona:

-

Smooth out connection points to reduce the risk of discharge.

-

Use larger diameter wires to reduce electric field strength around conductors.

-

Maintain ample separation between high-voltage components.

-

Use continuous insulation without gaps to prevent internal discharges.

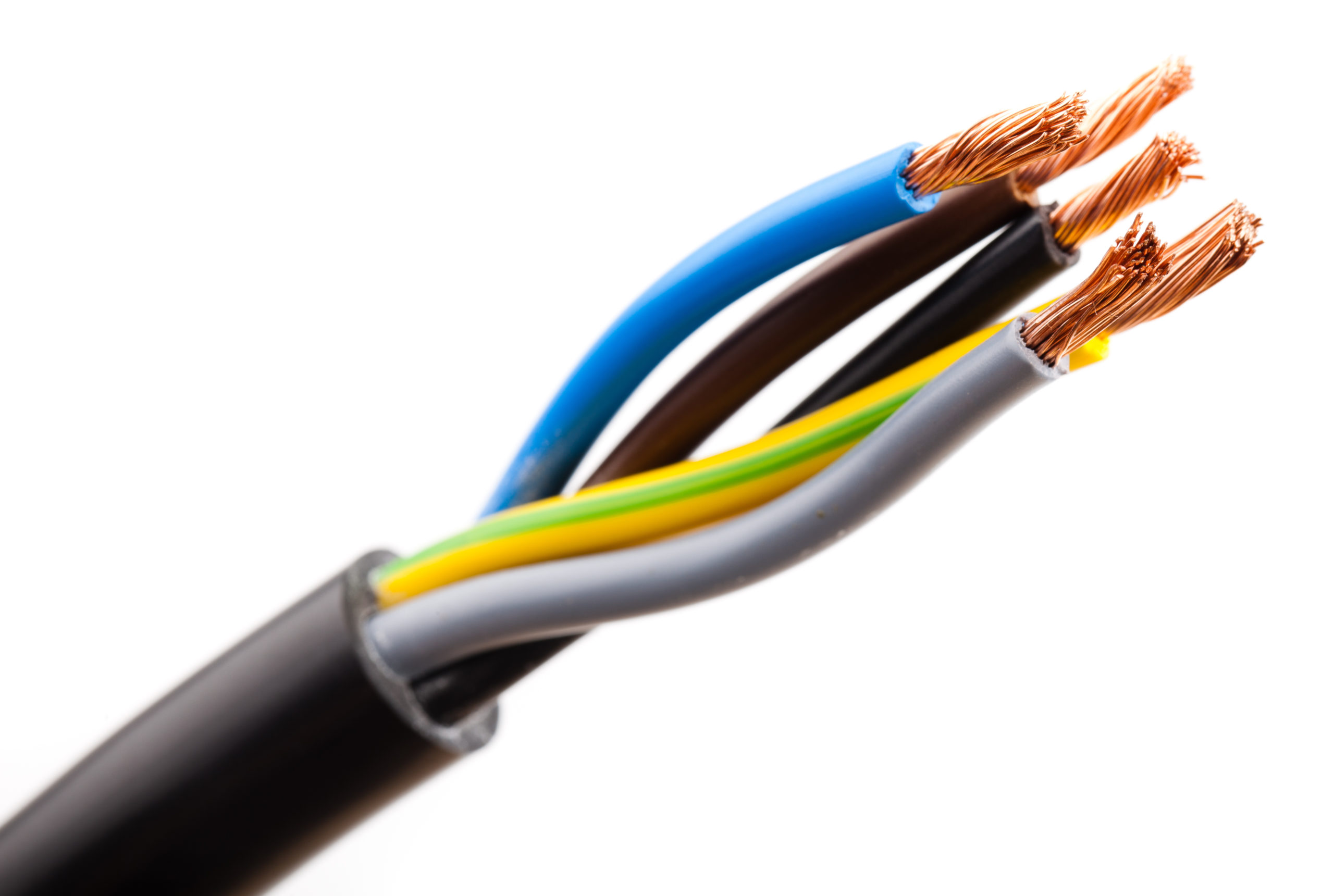

Figure 2. What Not To Do — Loose Wire Ends, Different Wire Thicknesses, Sharp Wire Bend.

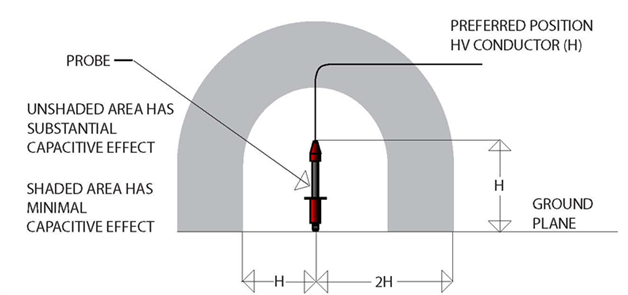

Fields and Interference

High voltages generate substantial electrical fields which can be influenced by nearby objects, including the operator. External electrical interference from sources like radio stations and military installations can also impact measurements. To mitigate these effects:

-

Keep measurement setups away from potential sources of interference

-

Employ proper shielding techniques to protect against external fields.

-

Avoid movement of objects or personnel near the measurement area during testing.

Figure 3. Diagram showing influence of external fields on high voltage.

Total System Uncertainty

Total system uncertainty encompasses all potential sources of error in a measurement setup. This includes:

-

Device and Divider Errors: Each component in the measurement system introduces its own level of error.

-

Operator Bias and Location Effects: The experience of the operator and the measurement environment can affect results.

-

Software Influence: Ensure the software used for data collection and analysis is accurate and reliable.

High-Voltage Test Equipment Needs to Fit the Application

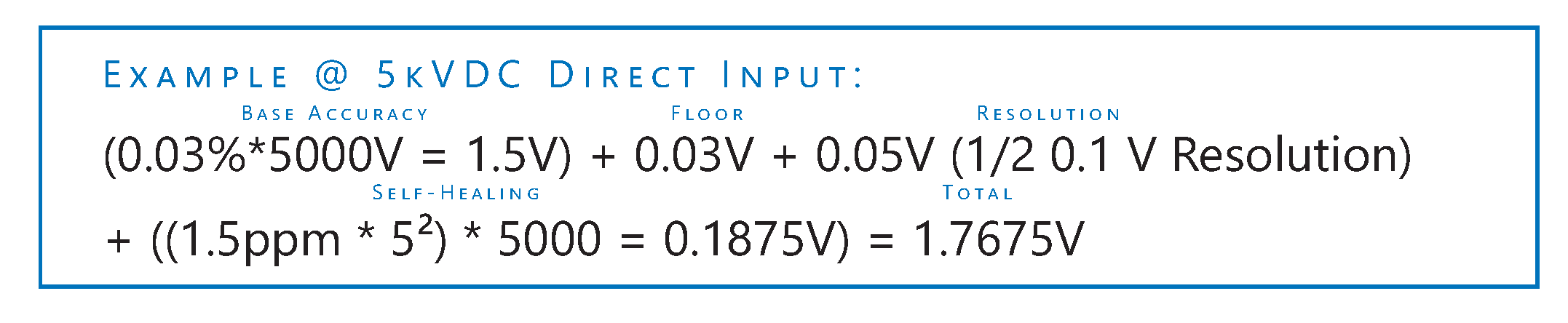

The types of devices used in standards and calibration labs worldwide can provide simultaneous AC/DC voltage, frequency, peak-to-peak, and crest factor readings. In commonly used equipment like the Vitrek 4700, the meter measures up to 10kV directly and up to 150kV with their proprietary Smart Probes. It also provides a chart mode for graphic documentation of high voltage drift, ramp time, overshoot, and sag — key variables that can define failure.

Accuracy calculations for equipment like the Vitrek 4700 are valid for one year from calibration. The accuracy specifications include the measurement uncertainties in the standards and methods employed by the manufacturer during calibration of the tester and probes. Measurement accuracy specification comprises base accuracy, floor, resolution, and high voltage self-heating specifications. For direct measurements, no additional calculations for accuracy at the terminal are required.

Performance and Automation

The best of the available test equipment utilizes Digital Signal Processing (DSP) technology that can provide outstanding AC and DC voltage accuracy, stability, and resolution. A simple example of such DSP is signal averaging, which can improve measurement precision or stability. Ideally the device should support test automation with built-in Ethernet and high-speed serial communication ports, making it fully programmable for tailored testing requirements. Some equipment, like the Vitrek 4700, include a USB printer port for capturing readings and obtaining hardcopy printouts of high voltage plots. The This meter and its SmartProbes come with an ISO17025 accredited calibration certificate, ensuring accuracy and traceability.

The Role of Accredited Laboratories

Accredited laboratories play a crucial role in maintaining measurement accuracy. These labs provide traceability to national and international standards, ensuring consistent and reliable calibration. For instance, Vitrek’s calibration lab is accredited by the American Association for Laboratory Accreditation (A2LA) to ISO

17025:2017 and ANSI/NCSL Z540-1-1994 standards. This ensures that all measurements are traceable to the International System of Units (SI) via national metrology institutes like NIST and NRC.

Conclusion

The calibration of high-voltage test equipment is not just a technical necessity but a cornerstone of safety and reliability. By adhering to rigorous standards and meticulously accounting for all sources of measurement uncertainty, we can ensure that high-voltage systems operate with precision and dependability. Accredited labs play an indispensable role by providing the expertise and traceability needed to uphold high standards.

As technology advances, the importance of accurate high-voltage measurements will only grow, making it essential for industries to invest in proper calibration practices. Ultimately, mastering high-voltage measurement is about safeguarding both the equipment and the people who rely on it, ensuring a safer and more efficient future for all.

Press Release: Vitrek Launches Next Gen Compliance Test Automation Software

Vitrek Launches Next Gen Compliance Test Automation Software

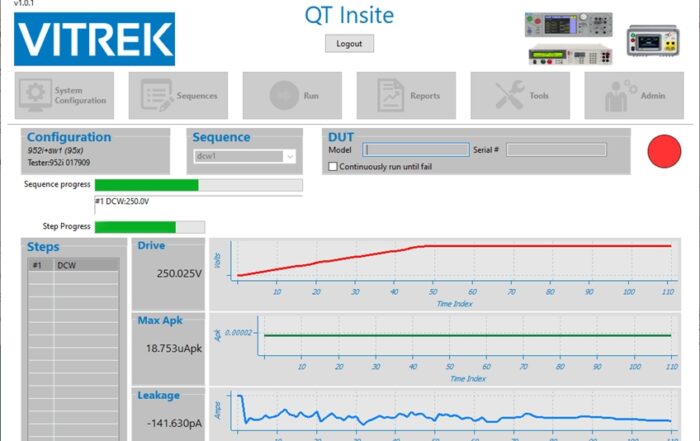

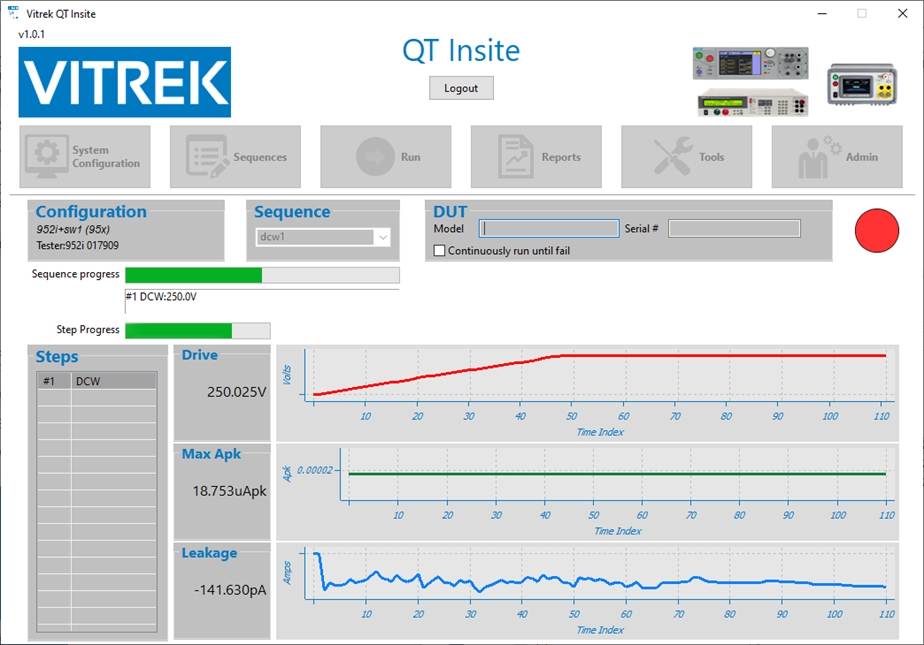

Introducing QT Insite™ — Vitrek’s Latest Advancement in High Voltage Test Automation

Lockport, IL—January 29, 2025— Vitrek, a US-based manufacturer of high-end test, measurement and signal recording equipment, announced today that it has introduced a new test automation software package — QT Insite. This, the latest in their line of Quick Test software releases, is distinguished by its streamlined use of system resources and robust features.

Lockport, IL—January 29, 2025— Vitrek, a US-based manufacturer of high-end test, measurement and signal recording equipment, announced today that it has introduced a new test automation software package — QT Insite. This, the latest in their line of Quick Test software releases, is distinguished by its streamlined use of system resources and robust features.

Designed to work with Vitrek’s 95x, 98x and V7x series of hipot testers as well as the company’s 964i high-voltage switches, QT Insite software helps automate test procedures by simplifying test design, set-up and data tracking.

With QT Insite software, complex high voltage test sequences can be programmed to run from a remote computer or uploaded to the hipot equipment itself. Once programmed, the floor operator can see specific test instructions then initiate the tests via a barcode scanner and even see how the test is progressing in real-time via user-friendly graphical displays.

Popular among medical, aerospace and manufacturing sub-assembly makers where the cost of errors are high, QT Insite software allows manufacturers to store data automatically on their network by model and serial number in a wide variety of configurable formats. The software also enables the data to be searched, filtered and exported.

Customizable operator permissions and user profiles in the software provide security over the test settings, making this a popular choice for applications where data security and traceability are critical.

Vitrek makes it easy to sample QT Insite software by offering a free trial version for up to 45 days.

“The goal of QT Insite software is to make it easier to use our testers in demanding applications,” said Chad Clark, Vitrek’s Vice President of Sales, adding, “For this software release, we reduced the price to simplify the decision whether to buy or design your own test software. Our test equipment enables both, so customers can decide for themselves by leveraging our 45-day free trial of the software.”

About Vitrek

Vitrek products are widely used in the aerospace industries, electric vehicles, medical, research and development markets, as well as by a wide variety of manufacturing industries. Vitrek product lines include a broad line of precision voltage generators and analyzers as well as hipot testers and switches.

Vitrek products are widely used in the aerospace industries, electric vehicles, medical, research and development markets, as well as by a wide variety of manufacturing industries. Vitrek product lines include a broad line of precision voltage generators and analyzers as well as hipot testers and switches.

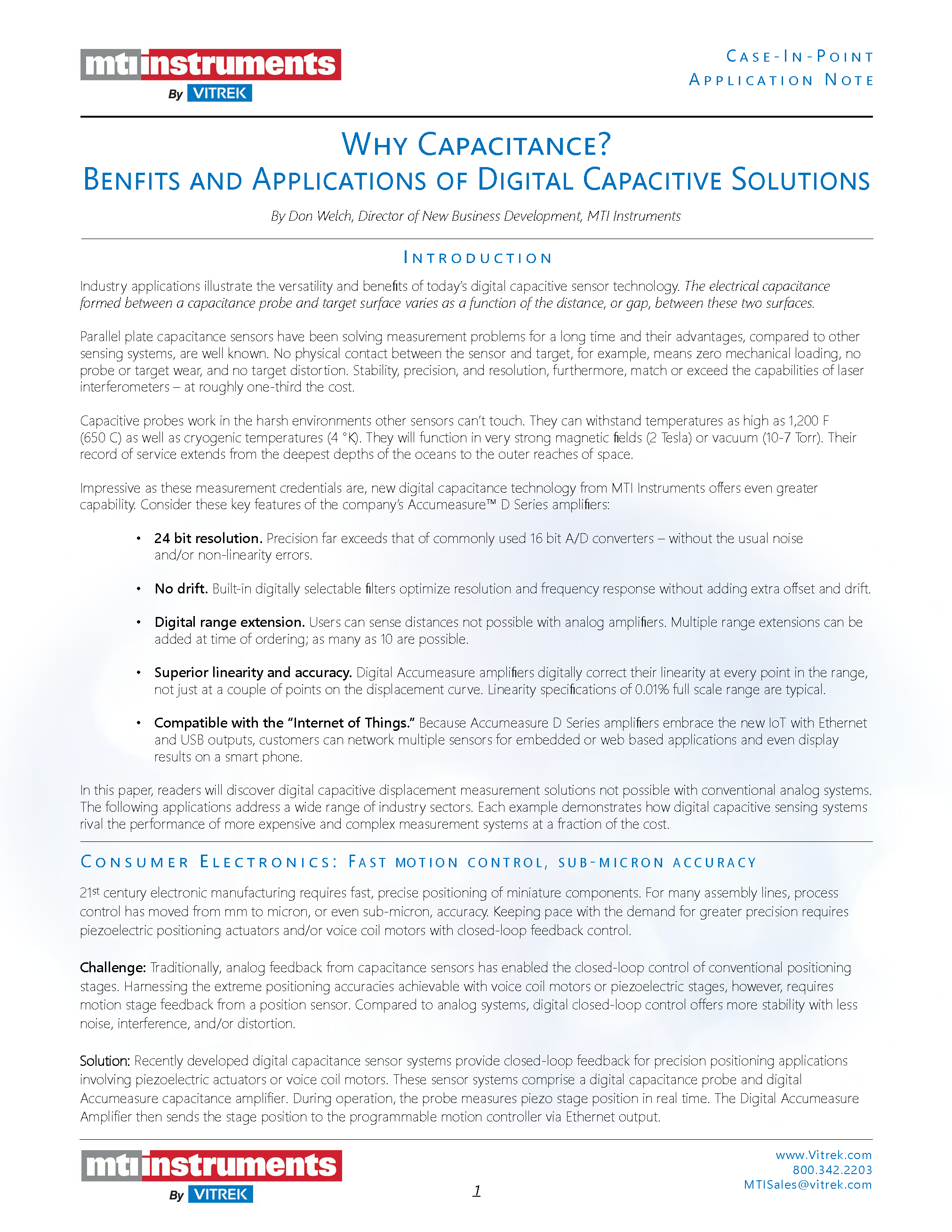

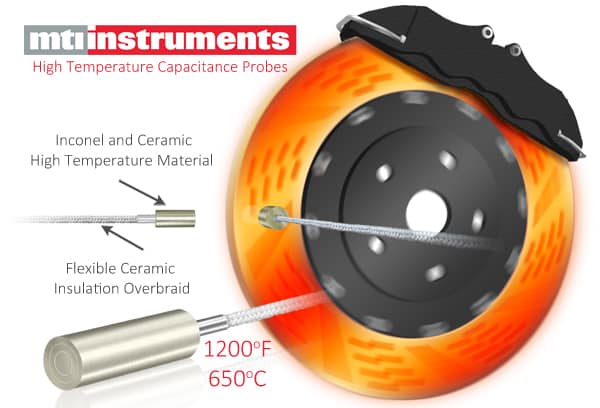

The Vitrek family of brands also includes: the MTI lines of capacitive measurement solutions for semiconductor wafer and precision film testing as well as jet engine balancing products; the GaGe digitizer cards which are recognized worldwide for combining high speeds with high-resolution and application flexibility.

Press Release: Vitrek Honored as Top Semiconductor Solution Provider of 2024

Vitrek Honored as Top Semiconductor Solution Provider of 2024

Semiconductor Review Magazine Recognizes Vitrek’s Industry-Leading Products are at the Forefront of Innovation in the Semiconductor Solutions Market.

Lockport, IL—January 22, 2025— Vitrek, a leader in high-performance test and measurement equipment, is proud to announce that it has been recognized as one of the Top Ten Semiconductor Solutions Providers of 2024 by Semiconductor Review Magazine. This award underscores Vitrek’s reputation and trust among customers and industry peers, as well as its innovative contributions to the semiconductor industry.

Lockport, IL—January 22, 2025— Vitrek, a leader in high-performance test and measurement equipment, is proud to announce that it has been recognized as one of the Top Ten Semiconductor Solutions Providers of 2024 by Semiconductor Review Magazine. This award underscores Vitrek’s reputation and trust among customers and industry peers, as well as its innovative contributions to the semiconductor industry.

The award was granted after evaluation by an expert panel of C-level executives, industry thought leaders, and the editorial board of Semiconductor Review. Vitrek’s comprehensive range of high-precision solutions, including products from its MTI Instruments and GaGe brands, played a significant role in earning this accolade.

Vitrek’s Achievements Recognize the Collective Impact of Its Three Brands:

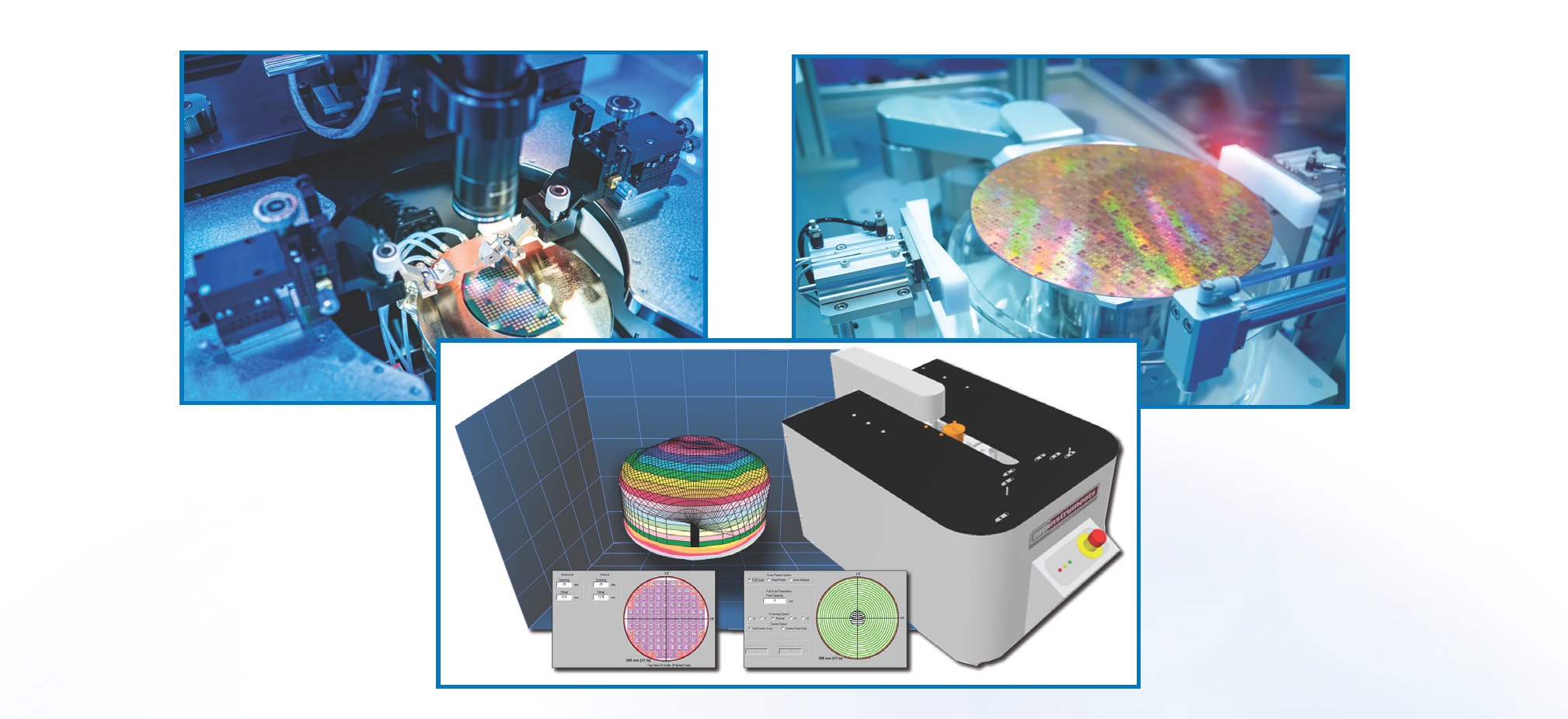

- MTI Instruments: Known for high-precision, non-contact capacitive measurement tools, the MTI line includes the semi-automatic Proforma 300iSA, which offers full wafer scanning and thickness accuracy of +/- 0.25 µm.

- GaGe: Specializing in high-resolution, high-speed digitizer cards capable of streaming vast amounts of data at high speeds, the GaGe products are integral to various applications, including measuring ion density, ultrasonically imaging chiplet bonds and identifying defective MOSFETs via high speed switching analysis.

- Vitrek: Renowned for precise high-voltage measurement, the Vitrek line of products are used in larger equipment such as ion implanters and automated test systems, among other applications.

“We are honored to receive this recognition from Semiconductor Review,” said Ken Ameika, Vitrek VP of Global Sales. “This award is a testament to our commitment to innovation, quality, and customer satisfaction. We will continue to push the boundaries of technology to meet the evolving needs of the semiconductor industry.”

Vitrek’s products are trusted by globally recognized compliance and standards organizations, including the National Institute of Standards and Technology (NIST) and Underwriters Laboratories (UL). Manufactured in the U.S. and supporting the CHIPS Act, Vitrek’s portfolio combines American ingenuity with a global reach, supported by a robust distribution network and U.S.-based servicing.

About Vitrek

Vitrek is a leading provider of high-performance test and measurement equipment, serving industries such as semiconductor, aerospace, automotive, medical, manufacturing and more. With a focus on innovation and quality, Vitrek delivers solutions that meet the rigorous demands of modern technology and industry standards. The Vitrek headquarters is located in Lockport, Illinois.

Vitrek is a leading provider of high-performance test and measurement equipment, serving industries such as semiconductor, aerospace, automotive, medical, manufacturing and more. With a focus on innovation and quality, Vitrek delivers solutions that meet the rigorous demands of modern technology and industry standards. The Vitrek headquarters is located in Lockport, Illinois.

Semiconductor Review: Vitrek Awarded Top Semiconductor Solutions Provider of 2024

Vitrek

High-Accuracy Measurement Tools from Silicon to Final Solution

Vitrek makes test and measurement solutions for everything from processors to power chips. The company’s broad industry presence is, in part, by design. Vitrek is the union of three complementary companies. Each delivers unique high-precision solutions:

- MTI Instruments delivers high-precision, non-contact, capacitive measurement tools.

- GaGe specializes in high-resolution, high-speed digitizer cards.

- Vitrek, now the parent brand, is renowned for precise hi-voltage measurement products.

“Before being merged, each of our companies had established a presence in the industry, addressing the need for high precision in unique ways that addressed critical needs,” says Sam Cremin, vice president of marketing.

![]()

The Proforma 300 iSA, a flagship product in MTI’s product portfolio, offers full wafer scanning and thickness accuracy to +/- 0.25μ—the equivalent of a smaller-sized inhaled smoke particle. The tool delivers raw mapping data as well as full 3-D images. It can highlight shape changes to wafers before and after processing, including film and coating stress calculations.

What sets the GaGe digitizer cards apart is not just the high resolution of their cards. It’s their ability to stream vast amounts of data at speeds capable of triggering a production line stop in milli-seconds. Typically integrated into larger solutions, the cards have been adopted to:

- Measure ion density and thickness in deposition equipment.

- Ultrasonically image bonds between chipsets and substrates.

- Detect minor noise frequency changes that indicate MOSFET defects.

- Rapidly ground power chips during thermal cycling, allowing more chips to be tested simultaneously.

As such, the GaGe products are the chameleons of the Vitrek family—they can be paired with different sensors and PCIe bus-based products for a range of applications.

While Vitrek high-voltage products are often sold as freestanding units, they are also used in larger equipment, such as ion implanters and automated test systems.

![]()

Vitrek’s accurate, rapid response product line reduces waste and accelerates the throughput of very precise chips. This ensures that only high-quality ICs, wafers and transistors proceed through production and testing, making the semiconductor market one of Vitrek’s most promising growth areas.

Adding to its growing name recognition, the testing products’ reputation for excellence is fortified by the trust of globally recognized compliance and standards organizations, including the National Institute of Standards and Technology and Underwriters Laboratories. These institutions now use Vitrek’s equipment in their testing labs, which is a testament to the product’s recognized quality and durability.

Manufactured in the U.S., Vitrek’s portfolio of products pairs American ingenuity with a global reach. A robust distribution network ensures these innovative solutions are available worldwide, while U.S.-based servicing guarantees rapid turnaround times and reliable product support.

“While Asian markets remain vital, growth in the U.S. and western regions is accelerating, driven by strategic initiatives like the CHIPS Act,” says Ken Ameika, vice president of sales. “We are well-positioned to serve customers across these geographies.”

![]()

![]()

Vitrek’s promise to stay ahead of industry trends is deeply embedded in its culture, reflected in its proactive knowledge acquisition and market engagement. It leverages a variety of channels to remain at the forefront of technological advancements and industry needs. From attending trade shows—whether as exhibitors or participants—to actively engaging with industry associations, the company prioritizes staying informed about the latest developments shaping the semiconductor and electrification sectors.

The pace of technical progress is persistent, and in this highstake game, Vitrek is the required change. With its products designed to perform flawlessly for years, minimizing the need for repairs and maximizing customer confidence, Vitrek ensures every microchip is perfect before it powers the next leap forward.

Press Release: Vitrek Adds New 16-Bit Resolution, 4 Channel A/D Card To GaGe Product Line

Vitrek Adds New 16-Bit Resolution, 4 Channel A/D Card to GaGe Product Line

Sabre Express Product Designed for Customers Needing High-Resolution & Mid-Level Speeds

November 13, 2024— Vitrek, a US-based manufacturer of high-end test equipment and signal recording systems, has added the Sabre Express, a 4-channel analog-to-digital converter card to its GaGe line of digitizer cards.

Featuring 250 MS/s, the Sabre Express card provides a 4-channel alternative to the GaGe line of 16-channel digitizer cards currently available offering 500 MS/s or 1 GS/s.

The Sabre Express features a 6GB/s PCIe x8 interface that can deliver real-time streaming to the host over sustained periods of time.

The 4-channel Sabre Express card can be combined with various PC solutions to serve as the heart of a wideband, multi-channel, RF/Microwave signal analysis and recording system. The card supports both Windows 10/11 and Linux operating systems and is offered with the GaGeScope PC Oscilloscope software, including development kits for C/C#, Python, LabVIEW and MATLAB systems.

“Customers have been coming to Vitrek looking for a pared-down high-resolution digitizer system for the wide-range of applications that do not require added speed and flexibility of our high-end systems.” Said Gary Schafer, Vitrek President, adding that the card offers the same outstanding signal-to-noise ratio that have made GaGe cards popular worldwide.

Click here or visit the Vitrek website for detail on the Sabre Express and Vitrek’s full link of digitizer cards.

About Vitrek and GaGe

The GaGe digitizer cards are recognized worldwide for combining high-speeds with high-resolution and application flexibility. Their outstanding signal-to-noise ratio distinguishes them in the marketplace for enabling users to achieve the highest effective number of bits at any speed. Vitrek’s Sabre Express Digitizer follows a long line of GaGe card products that have helped researchers and scientists solve hundreds of ground-breaking discoveries. Read overviews of how GaGe cards assisted these breakthroughs in the summaries of published white papers available on Vitrek.com.

Vitrek, the umbrella brand for all our test and measurement products, is also the world-recognized brand name for our high-voltage testing equipment, multi-point high-voltage switches and graphical power analyzers.

Vitrek’s MTI Instruments includes various precision engine rotor measurement/balancing tools and non-contact measurement tools used by industry leaders worldwide. For applications from jet engine balancing to semi-conductors and film measurement.

The Vitrek headquarters is located in Lockport, Illinois.

Press Release: Vitrek, LLC Expands Industry-Leading MTI PBS line to include the PBS eXpress™, a Portable Engine Balancing System for Business and Regional Jets

Vitrek, LLC Expands Industry-Leading MTI PBS line to include the PBS eXpress™, a Portable Engine Balancing System for Business and Regional Jets

Lightweight, portable system utilizes proven PBS technology for fast, highly accurate rebalancing of small-frame turbofan and turboprop engines

Lockport, IL—October 17, 2024— Vitrek, LLC, a U.S.-based manufacturer of advanced test and measurement equipment, introduces the enhanced PBS eXpress aircraft engine vibration analysis and balancing system. Designed to optimize engine performance in the small-frame turbofan and turboprop engines used in regional, business and smaller military jets, the PBS eXpress minimizes down-time and fuel costs by eliminating guesswork.

It features advanced algorithms based on commonly used engines to translate vibration and speed measurements into accurate balancing solutions. Available in rack mount as well as portable versions for on-runway testing, the system features intuitive setup and easy-to-operate visualization tools like vibration surveys, exportable data and PDF reporting. Supported propulsion systems include the most popular small-frame engines and APUs from major OEMs such as Honeywell, Rolls-Royce, P&W Canada, and Williams International.

The PBS eXpress features the same industry-leading technology developed for the PBS-4100+ family of balancing products used world-wide to support the larger frame engines on leading airlines and military jets.

Market-leading features of the portable PBS eXpress include:

- Modern Interface – Color touchscreen operates the entire Windows-based user interface.

- Extreme Simplicity – The Trim Balance Wizard streamlines the diagnosic process with simple-to-follow steps.

- Advanced Functionality – Rapidly calculates optimized engine balancing solutions accounting for existing weights on the engine and generates detailed “before and after” PDF reports.

- Convenience – Lightweight and portable system operates 6-plus hours between battery charges.

- Ease of Migration – Usable with common cables, pickups, and sensors.

Gary Schafer, President of Vitrek, LLC, said, “The PBS eXpress offers many of the advanced features found on the most sophisticated engine balancing systems – but with a price point and form factor optimized for MRO organizations and operators who maintain small-to-mid-sized corporate and regional jets.” He continued, “The PBS eXpress’s industry leading intuitive user-interface enables operators to perform vibration analysis and engine rotor balancing, with minimal training.”

The PBS eXpress will be on display at the NBAA-BACE Show at the Las Vegas Convention Center, West Hall in Las Vegas on Oct. 22-24. The product will be shown along with the PBS-4100+ for large frame jet engines and the portable1510A which allows technicians to bring a laboratory-grade precision function generator directly to the flight line.

About Vitrek and MTI Instruments

In 2022 MTI Instruments was purchased by Vitrek, LLC, a US-based designer and manufacturer of test and measurement tools. The Vitrek family of brands also includes the MTI line of capacitive measurement solutions for semi-conductor wafers and high-precision film products; the GaGe digitizer cards as well as the broad line of precision voltage generators and hi-pot testers that have long been offered by Vitrek.

Vitrek products are widely used not only in the aerospace industries, but the electrical vehicle, medical, research and development markets, as well as by a wide variety of electrical products makers.

Education & Training

Check out our recent presentation of Understanding Electrical Safety Testers at the 2018 San Diego Test Equipment Symposium!